Tobacco alcoholization fermentation equipment, alcoholization fermentation method and circulating air supply method

A technology of fermentation equipment and circulating air, which is applied in the fields of supplementary air circulating air supply, tobacco alcohol fermentation equipment, internal circulation and external circulation, and can solve the problems of condensed water cannot be exhausted, biological enzymes are warmed, humidified and oxygenated Inhomogeneity, uneven material moisture, etc., to achieve stable pressure and oxygen content, uniform distribution of oxygen content, and good drainage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

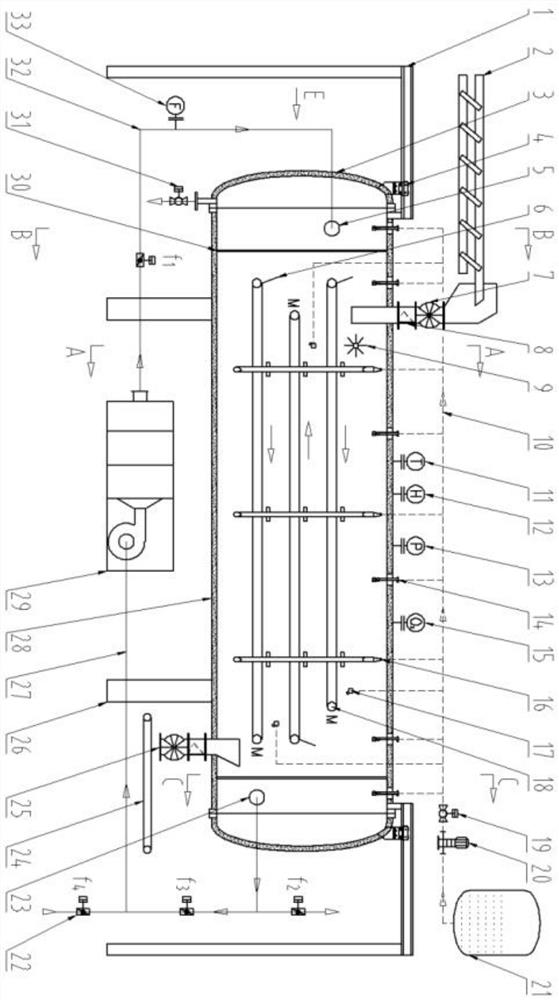

[0064] Specifically, as figure 1 As shown in the figure, the specific embodiment of the full batch alcoholization fermentation method is that, before feeding, various process parameters are preset. Generally, the hot air temperature is 40-50 ° C, the humidity is 60-80%, and the oxygen content is based on the requirements of biological enzymes. Setting, the air pressure in the cylinder is 0.01-0.05Mpa, and the hot air circulation method adopts the supplementary air circulation. At this time, the two sealing valves and the end doors 3 on both sides are in a closed state. Wait until the environment in the cylinder reaches the set requirements and start feeding. The tobacco with the premixed fermentation enzymes is loosened from the feeding vibrating tank 2 and evenly falls into the lower collection hood. At this time, the feeding sealing valve 8 is opened, and the tobacco in the collecting hood is continuously and evenly falling under the action of the feeding air lock 7. Enter ...

Embodiment 2

[0066] Specifically, as figure 1 As shown in the figure, the specific embodiment of the semi-batch alcoholization fermentation method is that, before feeding, various process parameters are preset, generally, the hot air temperature is 40-50 ° C, the humidity is 60-80%, and the oxygen content is based on the requirements of biological enzymes. Setting, the air pressure in the cylinder is 0.01-0.05Mpa, and the hot air circulation method adopts the supplementary air circulation. At this time, the two sealing valves and the end doors 3 on both sides are in a closed state. Wait until the environment in the cylinder reaches the set requirements and start feeding. The tobacco premixed with fermentation enzymes is loosened from the feed vibrating tank 2 and evenly falls into the lower collection cover. At this time, the feed sealing valve is opened, and the tobacco in the collection cover falls continuously and evenly under the action of the feed air lock 7. The first layer of mesh ...

Embodiment 3

[0068] Specifically, as figure 1As shown in the figure, the specific embodiment of the continuous alcoholization fermentation method is that, before feeding, various process parameters are preset. Generally, the hot air temperature is 40-50 ° C, the humidity is 60-80%, and the oxygen content is set according to the requirements of biological enzymes. The air pressure in the cylinder is 0.01-0.05Mpa, and the hot air circulation method adopts the supplementary air circulation. At this time, the two sealing valves and the end doors 3 on both sides are in a closed state. Wait until the environment in the cylinder reaches the set requirements and start feeding. At this time, the two sealing valves of the inlet and outlet, as well as the inlet air lock 7 and the outlet air lock 25 are opened at the same time. The tobacco premixed with fermented enzymes is loosened from the feed vibrating tank 2 and evenly falls into the lower collection hood. Under the action of the feed air lock 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com