Surface treatment device

A surface treatment device and surface treatment technology, applied in transportation and packaging, lighting and heating equipment, furnace components, etc., can solve the problems of reduced productivity, prone to mechanical conflicts, uneven surface treatment conditions, etc., to prevent non-conductor , Improving the delivery accuracy and reducing the effect of holding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

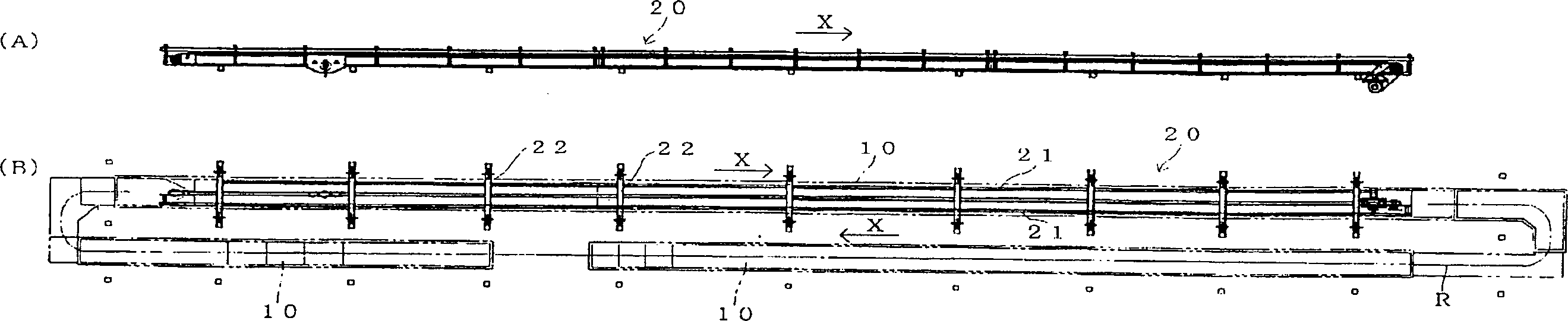

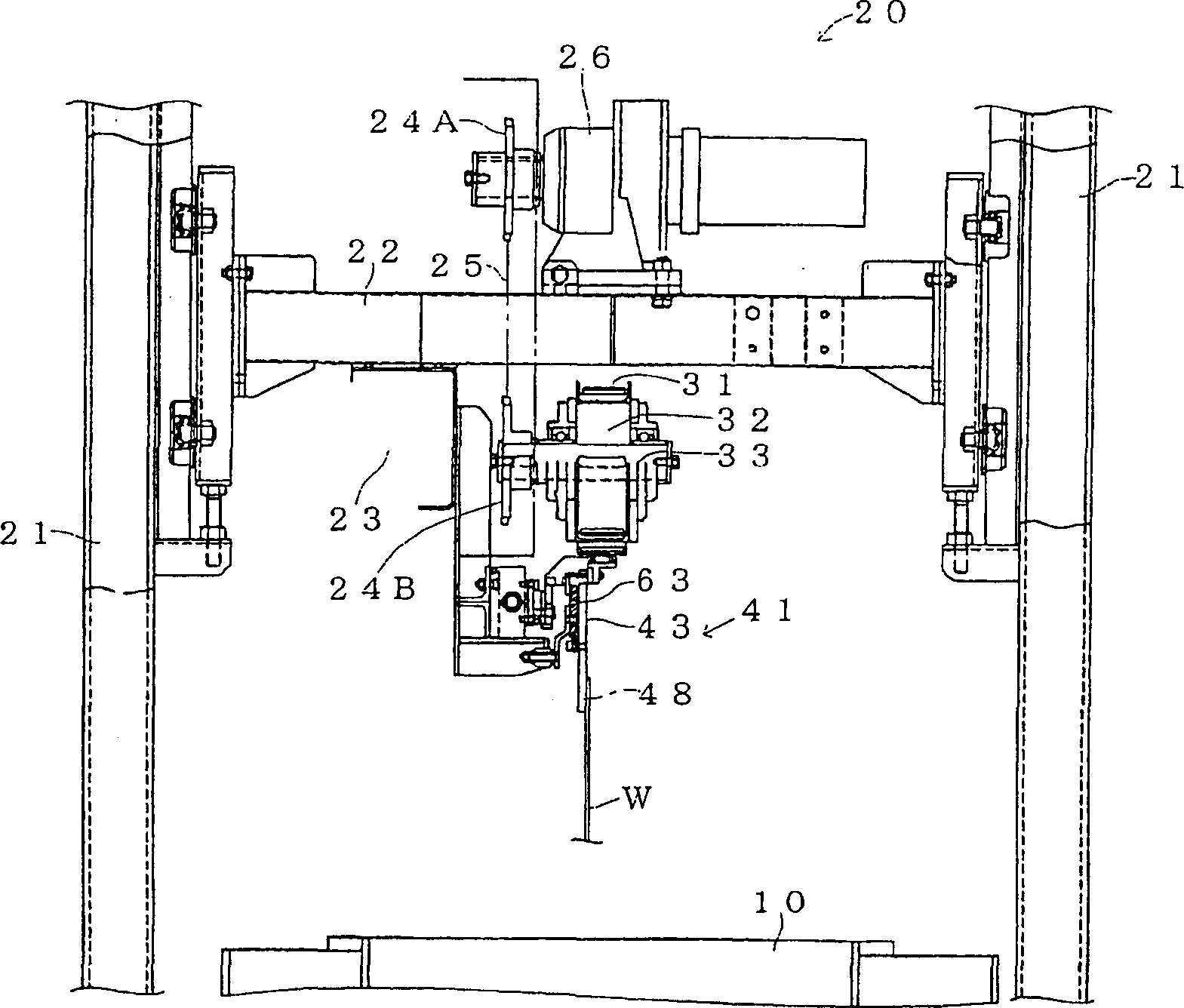

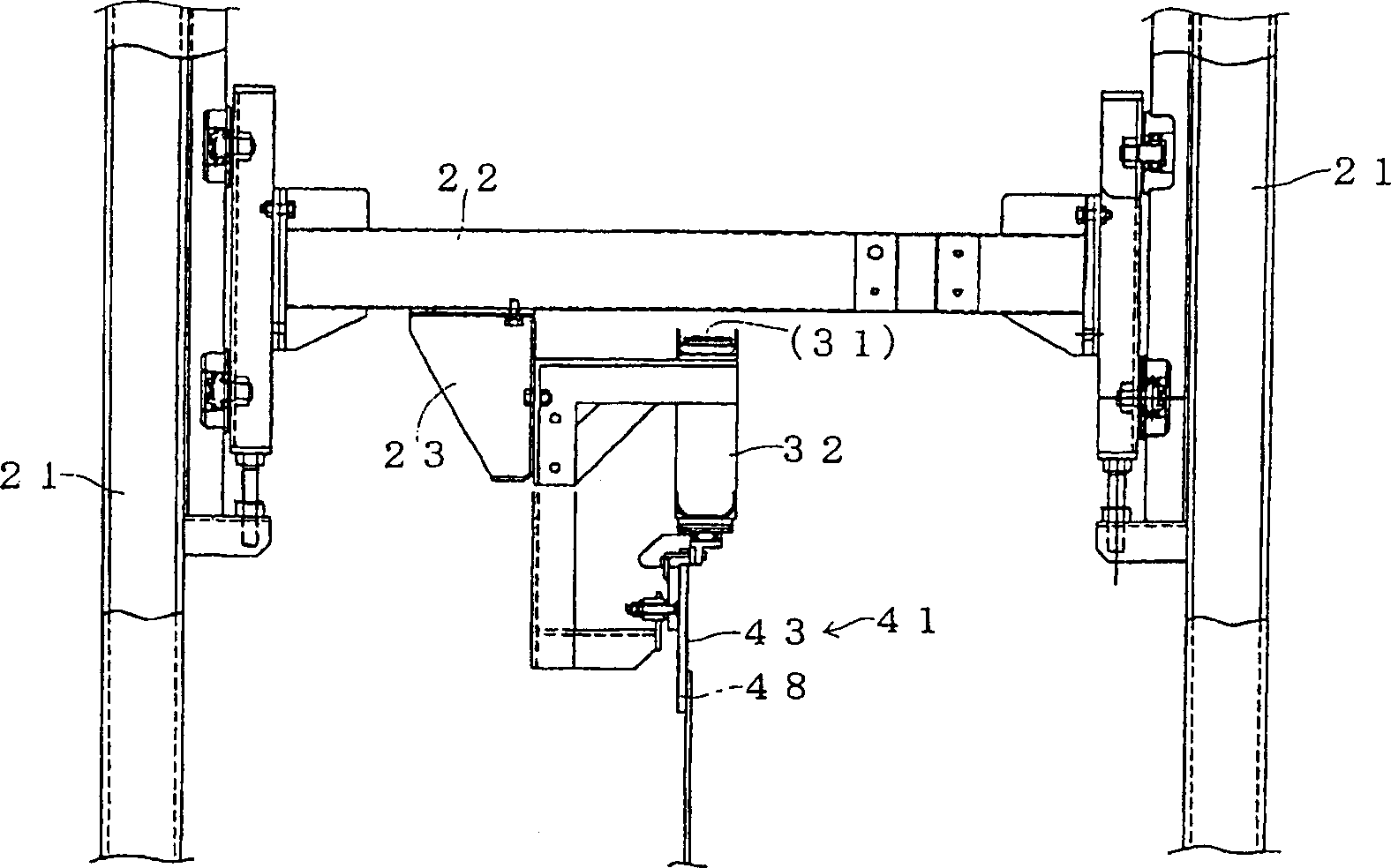

[0045] Surface treatment device of the present invention such as Figure 1 to Figure 6 As shown, the conveyer 31 that can move the conveying mechanism 20 in the conveying (X) direction can maintain a vertical hanging posture with a plurality of hangers 41 that hold a flat object (work W) at intervals in the X direction. The suspension loading and unloading mechanism 51 that is installed or separated on the conveyor 31 under the state of the suspension is constituted, and this suspension loading and unloading mechanism 51 has a plurality of ring-shaped materials 54 and A plurality of protruding materials 58 installed on one side of each suspension (or one side of the conveyor) can be engaged and separated by elastic deformation of both (or at least one of) the ring material 54 and the protruding material 58, At the same time, in the engaged state of both 54 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com