Conveying and cleaning machine for automobile part machining

A technology for auto parts and washing machines, which is applied in the direction of using liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., which can solve the problems of limited cleaning effect of flushing devices, achieve good cleaning effect, improve cleaning effect, Guaranteed cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following examples are for illustrative purposes only and are not intended to limit the scope of the invention.

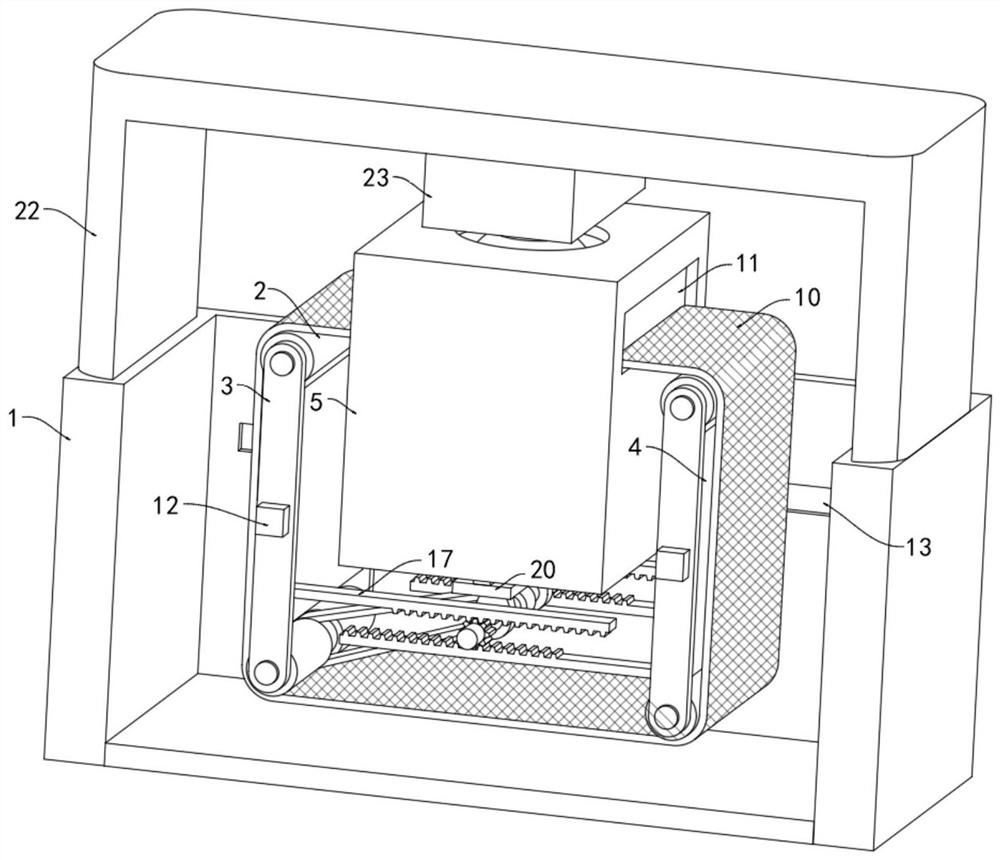

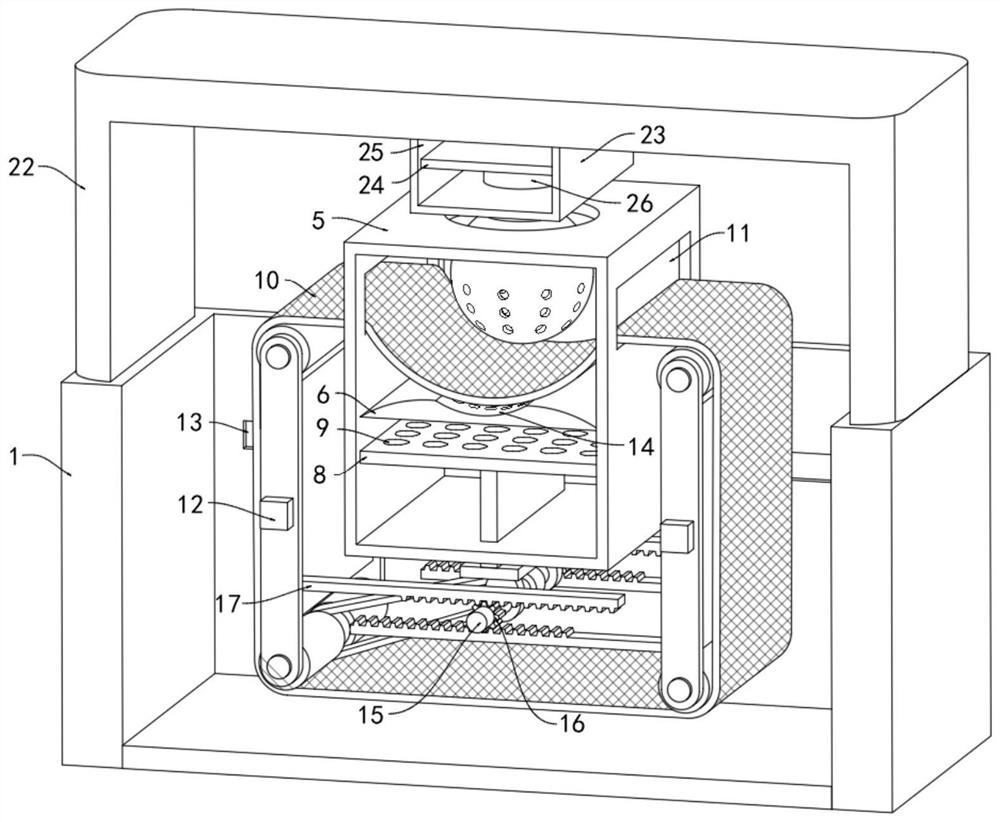

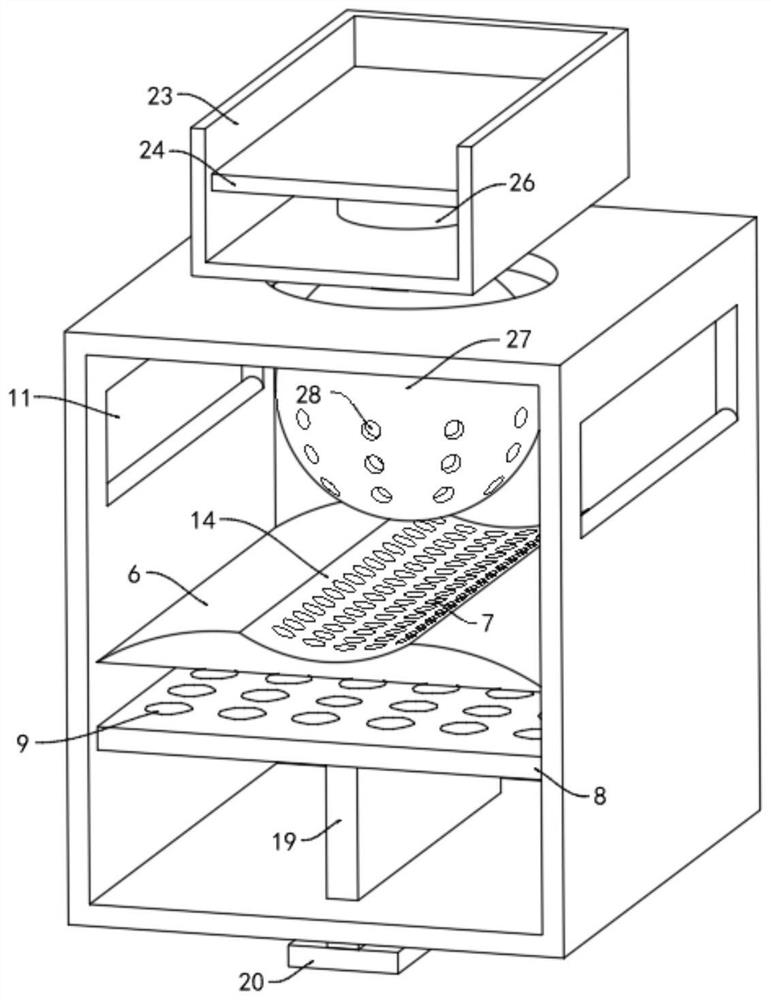

[0027] like Figure 1-5 As shown in the figure, a conveyor cleaning machine for processing automobile parts includes a frame body 1 with an open upper end, and two pairs of rotating rollers 2 arranged horizontally are arranged in the frame body 1, and each pair of rotating rollers 2 are located in the same vertical In the plane, the ends of each pair of rotating rollers 2 close to each other are provided with connecting plates 3 , and the rotating rollers 2 are rotatably connected with the connecting plates 3 .

[0028] It should be noted that, the outer side wall of each connecting plate 3 is fixedly connected to the limit block 12, the inner side wall of the frame body 1 is provided with a transverse groove 13 matched with the limit block 12, and the limit block 12 is slidably connected with the transverse groove 13. The entire frame can only be moved...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com