Magnetorheological polishing device with grinding head self-repairing function

A magnetorheological polishing and self-healing technology, applied in the polishing field, can solve the problems of pollution of flexible grinding heads, poor polishing quality, complicated operation, etc., and achieve the effects of long service life, simple operation and simple device structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

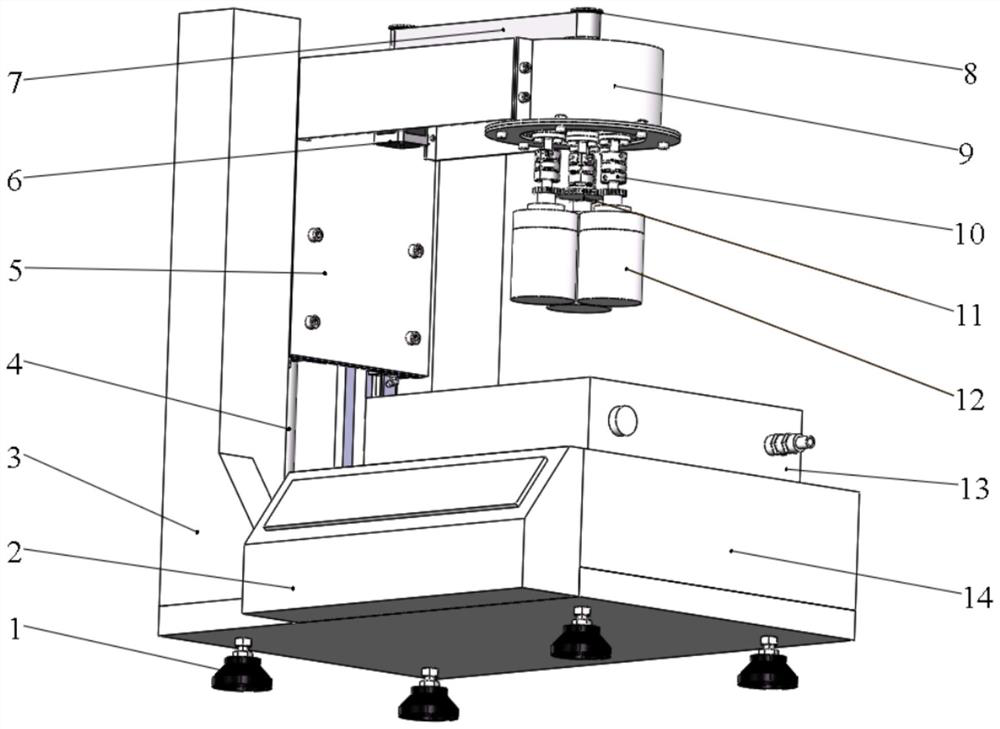

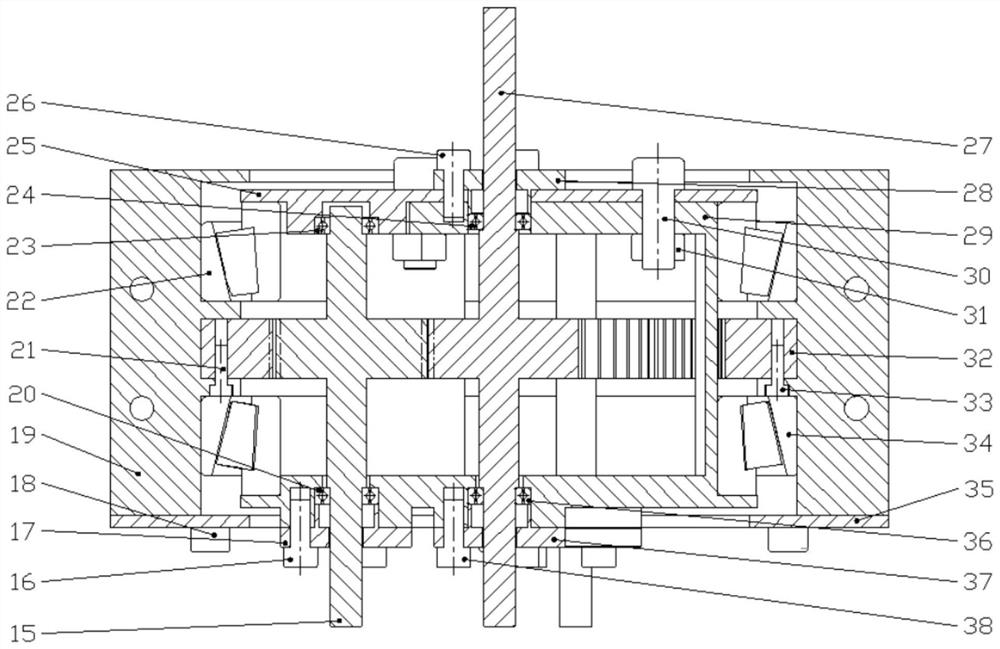

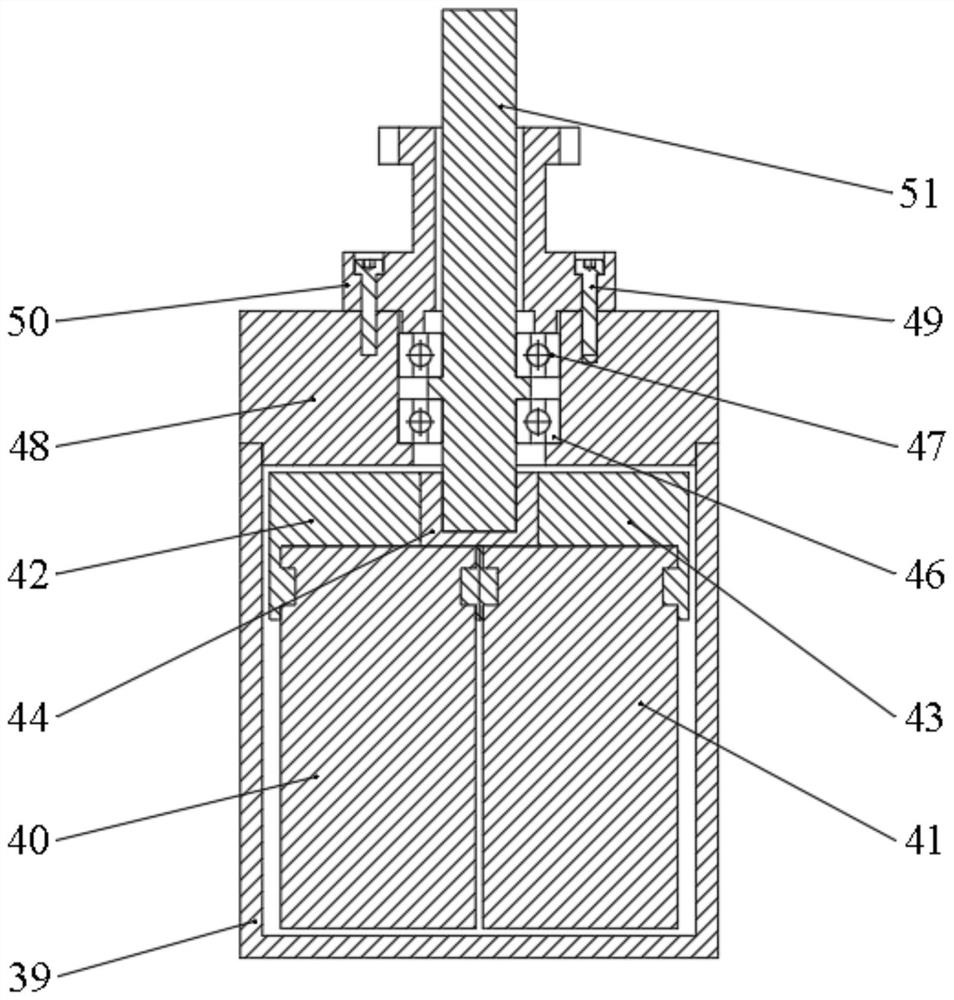

[0019] A magnetorheological polishing device with self-repairing grinding head is composed of a foot cup 1, an instrument operation panel 2, a frame 3, a ball screw module 4, a fifth connecting piece 5, a motor 6, a synchronous belt 7, and a synchronous pulley. 8. The transmission device 9, the coupling 10, the third gear shaft 11, the polishing head 12, the vacuum adsorption platform 13, and the fixture installation platform 14 are composed; the foot cup 1 is installed on the frame 3; the fifth connector 5 is fixed on the ball screw module 4; the ball screw module 4 is fixed on the rack 3; the fixture mounting platform 14 is mounted on the rack 3; the instrument operation panel 2 is mounted on the fixture mounting platform 14; the vacuum adsorption platform 13 is installed on the fixture installation platform 14; the motor 6 is fixed on the fif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com