A kind of branch point fracture type hyperbranched resin and its preparation method and application

A technology of hyperbranched resin and branch point, which can be applied to biocide-containing paints, coatings, anti-fouling/underwater coatings, etc., and can solve the problem that the resin cannot be detached from the coating surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

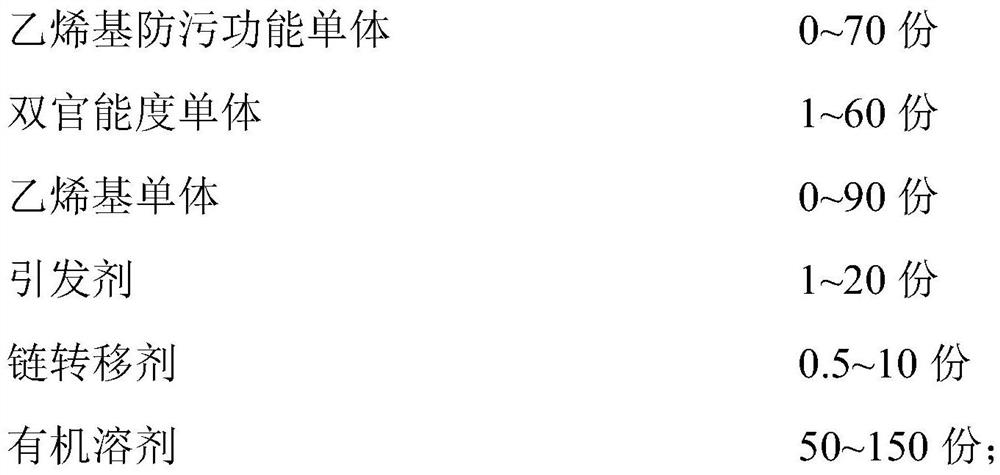

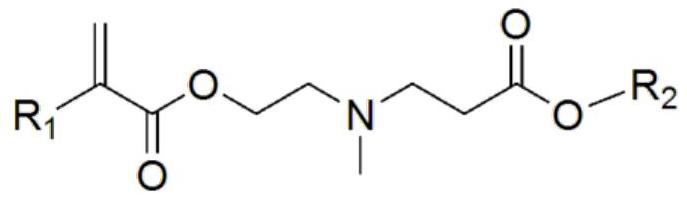

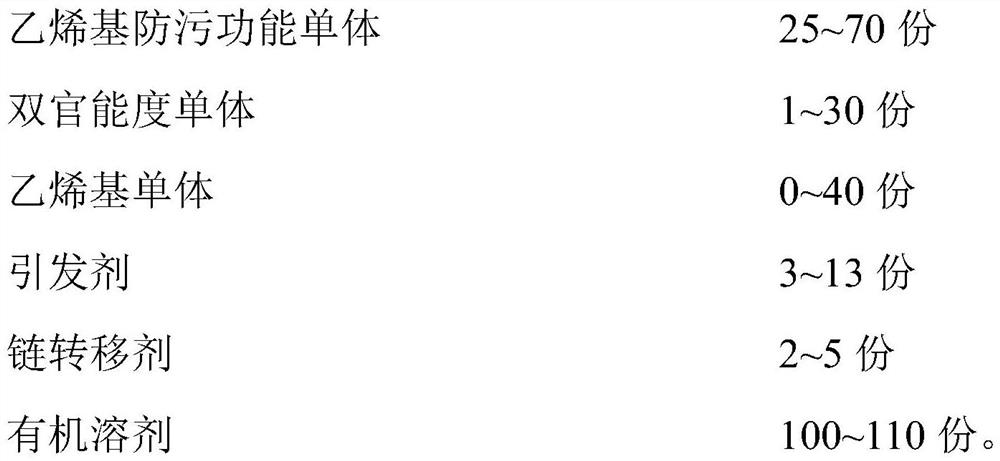

Method used

Image

Examples

Embodiment 1

[0073] Under stirring conditions, add 50g of xylene and 35g of propylene glycol methyl ether to the reaction vessel, raise the temperature to 90°C under a nitrogen atmosphere, and dropwise add 50g of bis(trimethylsiloxane)methyl methacrylate in 6 hours. Silicone ester (purchased from Momentive, USA), 20g ethyl acrylate, 30g polyglycolide with a molecular weight of 500g / mol at both ends of the vinyl group, 5g azobisisobutyronitrile, 2g diisopropyl disulfide The mixture of xanthate and 10g dimethylbenzene forms, after dropwise addition, continue to dropwise add the mixture of 0.5g di-tert-butyl peroxide and 10g dimethylbenzene in 30 minutes, then stir for 1.5 hours again, obtain hyperbranched silicon base Self-polishing resin.

[0074] The number average molecular weight Mn of the hyperbranched silicon-based self-polishing resin in the present embodiment is 4.5×10 3 g / mol, the silicon content is 4.6%, and the acid value is 92mgKOH / g; its paint film adhesion is grade 2; the drag...

Embodiment 2

[0076] Under the condition of stirring, add 20g of xylene and 70g of methyl isobutyl ketone into the reaction vessel, raise the temperature to 95°C under nitrogen atmosphere, and dropwise add 70g of tri-n-butylsilyl methacrylate (purchased In Bailingwei Technology Co., Ltd.), 30g magnesium acrylate, 2g azobisisovaleronitrile, 5g S-(thiobenzoyl) thioacetic acid, and 10g methyl isobutyl ketone. After the dropwise addition, keep warm for 3 hours , and then dropwise added 1 g of azobisisobutyronitrile and 10 g of xylene at a constant speed within 30 minutes, and stirred for another 4 hours to obtain a hyperbranched silicon-based self-polishing resin.

[0077] The number average molecular weight Mn of the hyperbranched silicon-based self-polishing resin in the present embodiment is 4.5×10 3 g / mol, the silicon content is 6.9%, and the acid value is 138mgKOH / g; its paint film adhesion is grade 1; the drag reduction rate is 4.8%; it is compounded with 10wt% 5-octyl-2-furanone to prepa...

Embodiment 3

[0079] (1) Synthesis of vinyl zinc ester monomer:

[0080] Add 10.4g of zinc oxide, 20g of propylene glycol methyl ether and 7g of xylene to the reaction vessel, heat to 75°C, dropwise add a mixture of 9.3g of acrylic acid, 7.7g of acetic acid and 1g of deionized water at a constant rate, and control it within 3 hours After the dropwise addition, after the dropwise addition, the insulation reaction was carried out for 2 hours, and the solvent was removed by rotary evaporation to obtain the vinyl zinc ester monomer;

[0081] (2) Synthesis of hyperbranched zinc-based self-polishing resin:

[0082] Under the condition of stirring, add 50g of xylene and 35g of propylene glycol methyl ether into the reaction vessel, raise the temperature to 90°C under a nitrogen atmosphere, and add 25g of vinyl zinc ester monomer, 30g of methacrylic acid-2 - Methoxyethyl ester, 15g methyl methacrylate, 30g polycaprolactone with a molecular weight of 500g / mol and vinyl groups at both ends, 5g azobi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com