Unidirectional cloth compounding method capable of controlling tension stability of unidirectional cloth

A unidirectional cloth and tension technology, applied in chemical instruments and methods, lamination auxiliary operations, lamination and other directions, can solve the problems of unbalanced unidirectional cloth tension, composite cloth wrinkle, large tension difference, etc., to save labor , improve the degree of automation, improve the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

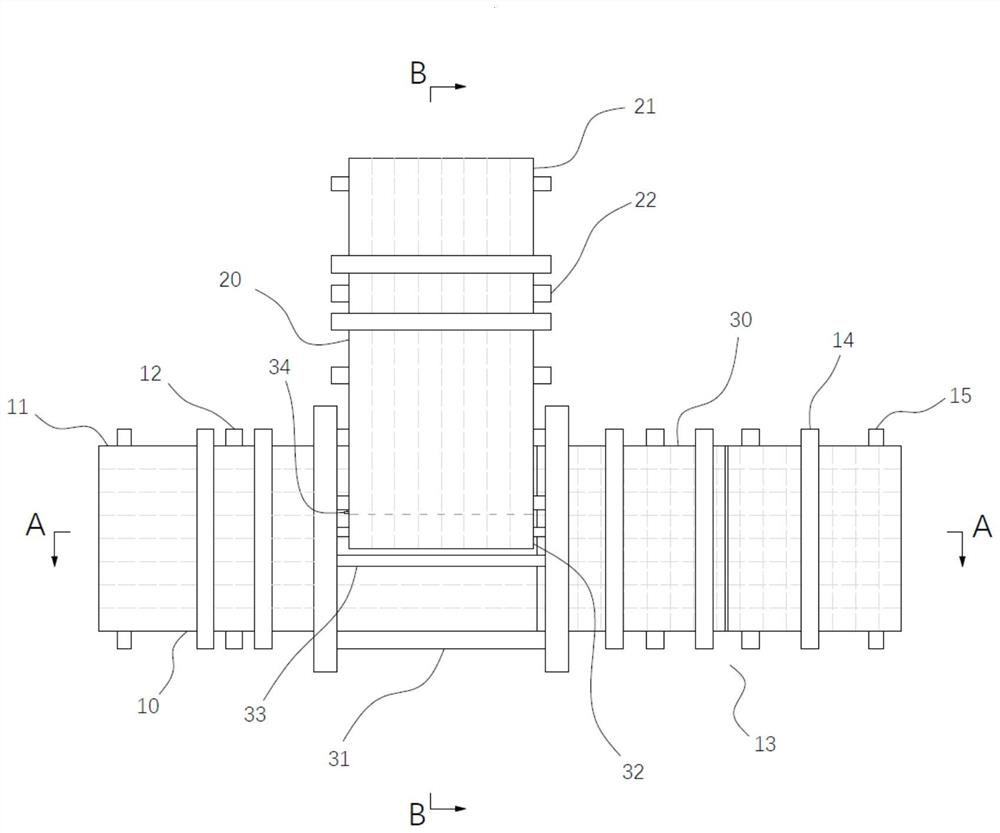

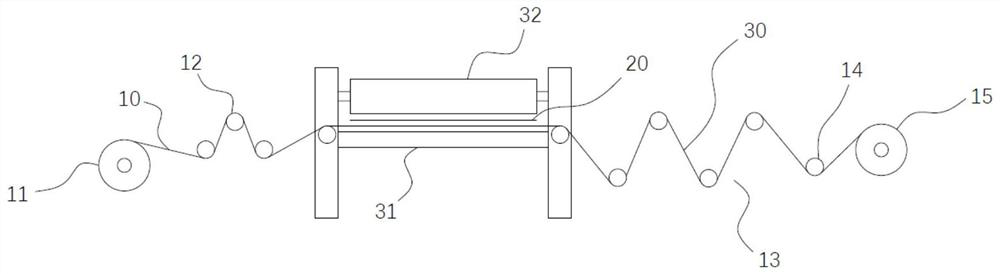

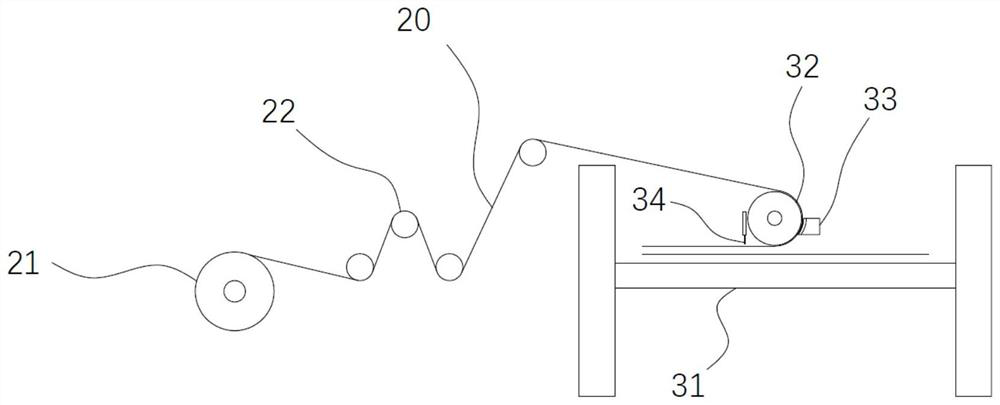

[0072] like Figure 1-4 As shown, this embodiment relates to a compounding device that can control the tension of unidirectional cloth to stabilize, including a longitudinal unit, a transverse unit and a compounding unit. The longitudinal unit includes a longitudinal unwinding device 11, a first tension roller 12, a tension separation device 13 composed of a group of conveying rollers, a third tension roller 14, a winding device 15, and a longitudinal direction not shown in the figure. Unwinding power unit and rewinding power unit. The transverse unit includes a transverse unwinding device 21, a second tension roller 22, and a transverse unwinding power device not shown in the figure. The compounding unit includes a compounding platform 31, a hot-pressing roller 32, a clamping device 33, a cutting device 34, and an air blowing device 35, wherein the surface of the compounding platform 31 is provided with a high-temperature resistant rubber pad, and the hot-pressing roller 32 ...

Embodiment 2

[0093] The equipment of this embodiment is the same as that of Embodiment 1, and the difference lies in the compounding process. The compounding process of this embodiment is as follows: Figure 5 shown, the specific steps are as follows:

[0094] Step a): as Figure 5 As shown in a, in the initial state of the compounding process, the hot-pressing roller 32 is located at the left edge of the longitudinal unidirectional cloth 10, the rotating shaft of the hot-pressing roller 32 is in a braking state, and the hot-pressing roller 32 and the clamping device 33 will Clamp to the cloth 20;

[0095] In the initial state, the hot-pressing roller 32 and the clamping device 33 are in a clamping state. In the clamping state, the rotating shaft of the hot-pressing roller 32 is in a state of braking and cannot rotate, and the hot-pressing roller 32 and the clamping device are in a state of being braked and unable to rotate. 33 fits snugly, so the transverse unidirectional cloth 20 is cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com