Hub bearing high-pressure washing sealing performance detection equipment

A technology of tightness detection and high-pressure flushing, which is used in liquid/vacuum measurement for liquid tightness, by detecting the appearance of fluid at the leak point, etc., which can solve problems such as lack of detection equipment and facilitate data comparison and data adjustment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

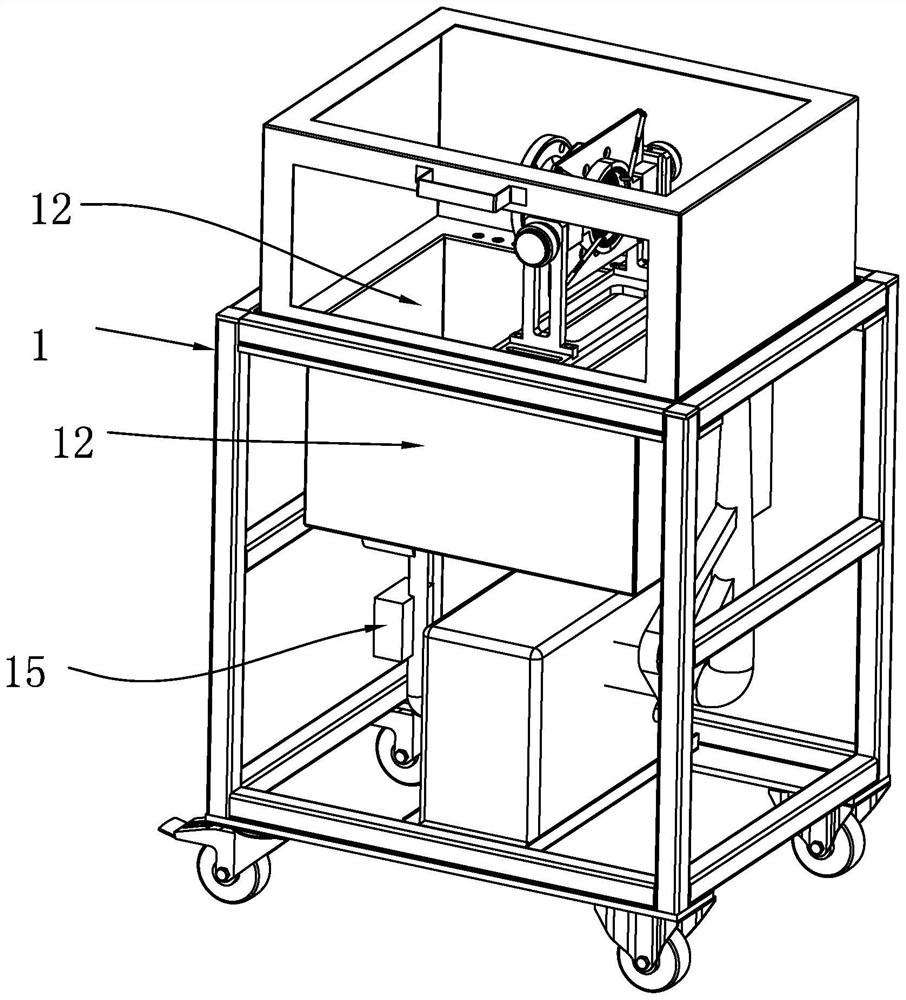

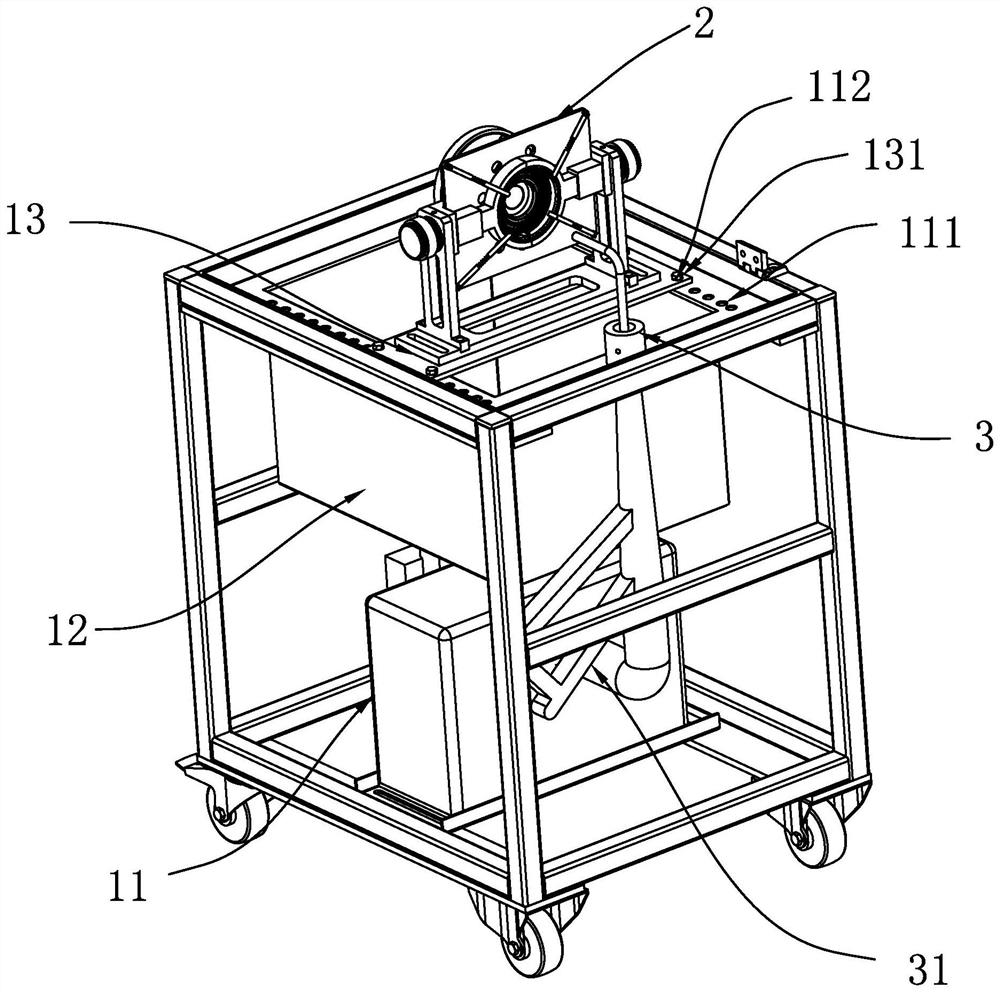

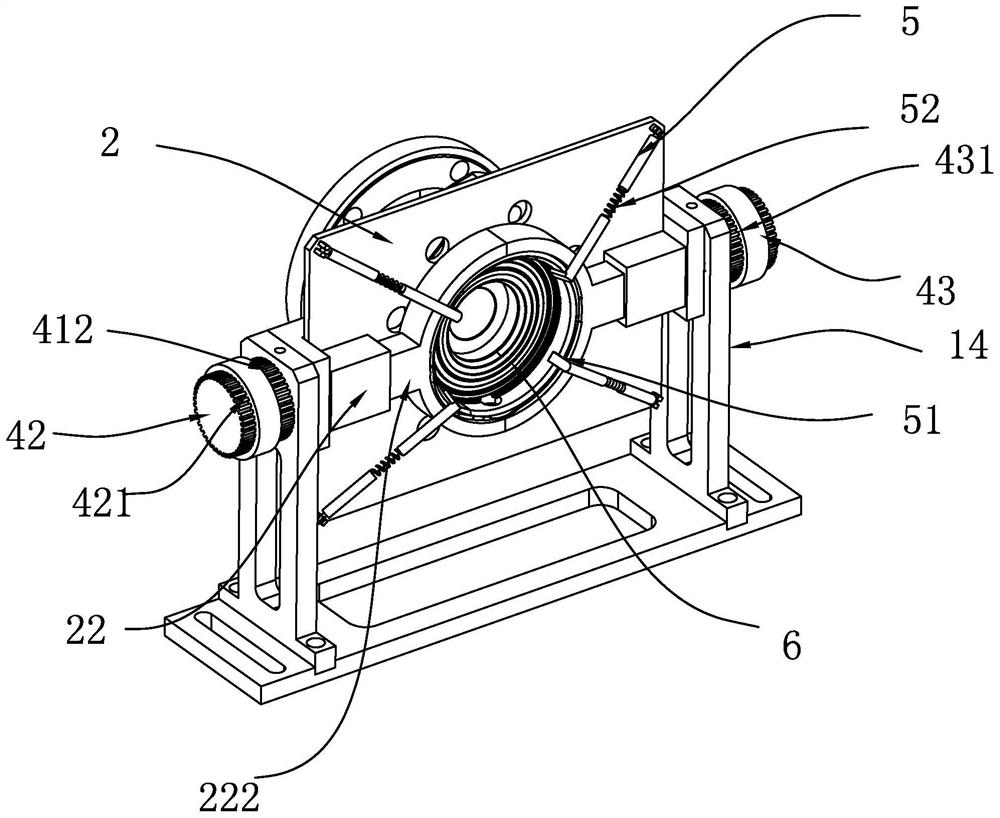

[0024]The present invention provides a wheel hub bearing high-pressure flushing tightness detection equipment, which includes an operation table 1, the operation table 1 is hollowed with a water storage chamber 11, and the end surface of the operation table 1 is provided with a water collection tank 12, and the operation table 1 A support plate 13 is arranged on the end surface, and the support plate 13 is arranged above the opening of the sump 12. Two vertical plates 14 are arranged on the support plate 13, and a fixing plate 2 is arranged between the two vertical plates 14. , the fixed plate 2 is provided with an accommodating hole 21 for the external bearing to be tested, and the inner peripheral wall surface of the accommodating hole 21 is a contact surface for contacting the outer peripheral wall of the outer ring of the bearing to be tested. The fixed plate 2 is provided with a fixing piece for stably fixing the external bearing to be tested on the fixed plate 2, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com