Design method and device for cooling high-temperature gas with equal Mach number

A high-temperature gas and cooling device technology, applied in design optimization/simulation, computer-aided design, calculation, etc., can solve problems such as inability to compress high-temperature incoming flow, high Mach number at flight altitude, and recycling of high-temperature exhaust gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

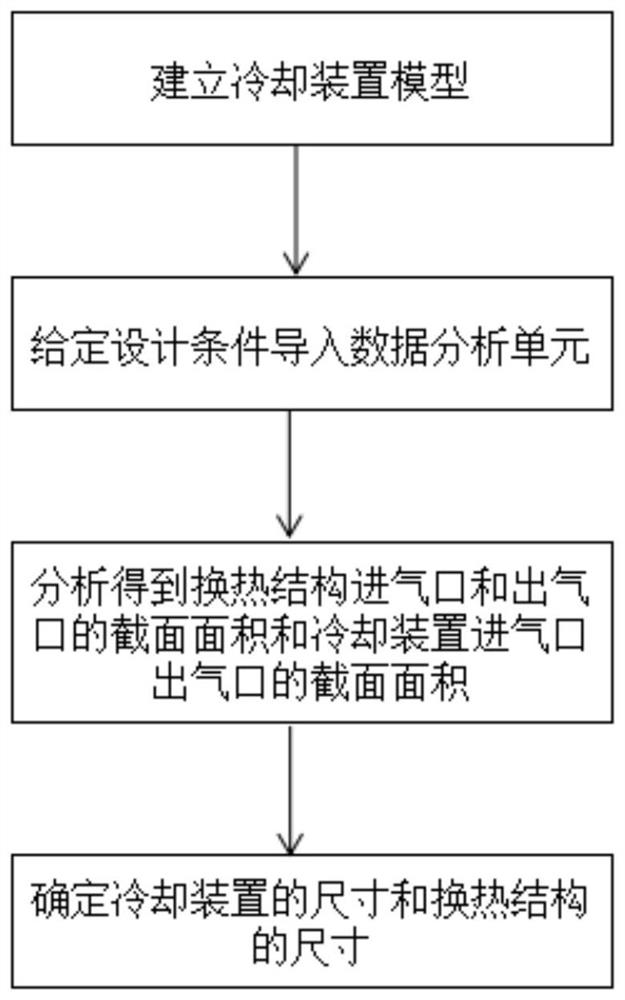

Method used

Image

Examples

Embodiment 1

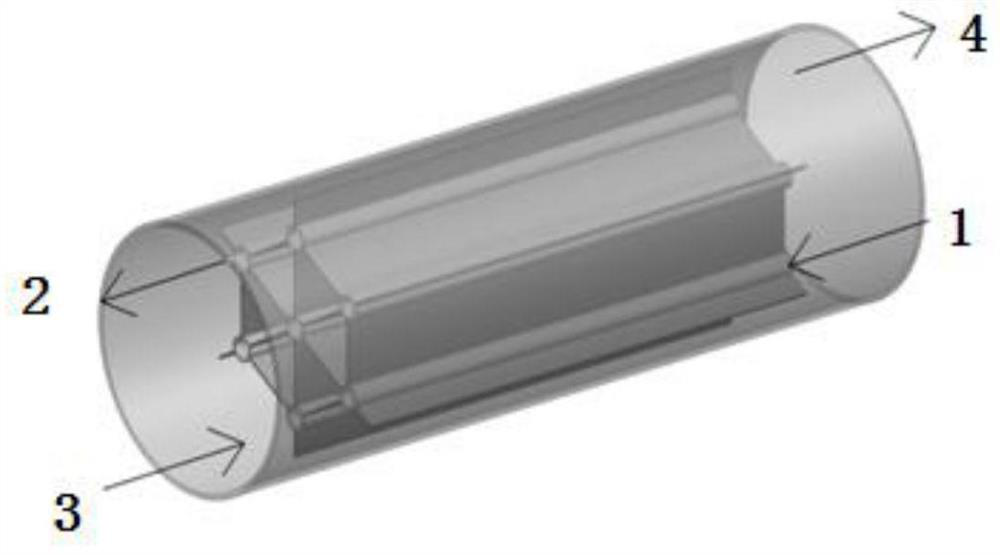

[0066] Design Goal: Design a pure air cooling device with a circular cross-section, operating at a maximum Mach number of 4.2.

[0067] Design conditions: The air flow rate at the air inlet and outlet of the cooling device is Mach 0.2, and the gas flow rate in the heat exchange structure is maintained at Mach 0.3; the total temperature of the air to be pre-cooled is the stagnation temperature of the incoming air corresponding to Mach 4.2, and the flow rate is assumed It is 2kg / s (before flowing into the cooling device, the high-speed incoming air of Mach 4.2 is decelerated to Mach 0.2 through the air inlet of the cooling device); the air static pressure of the air inlet of the heat exchange structure is 1.3atm, and the static pressure of the air outlet is 1.0atm , the temperature is 350K.

[0068] According to the analysis of the above design conditions, the design parameters of the heat exchange structure are given; assuming that the incoming flow rate increases to 4kg / s, or ...

Embodiment 2

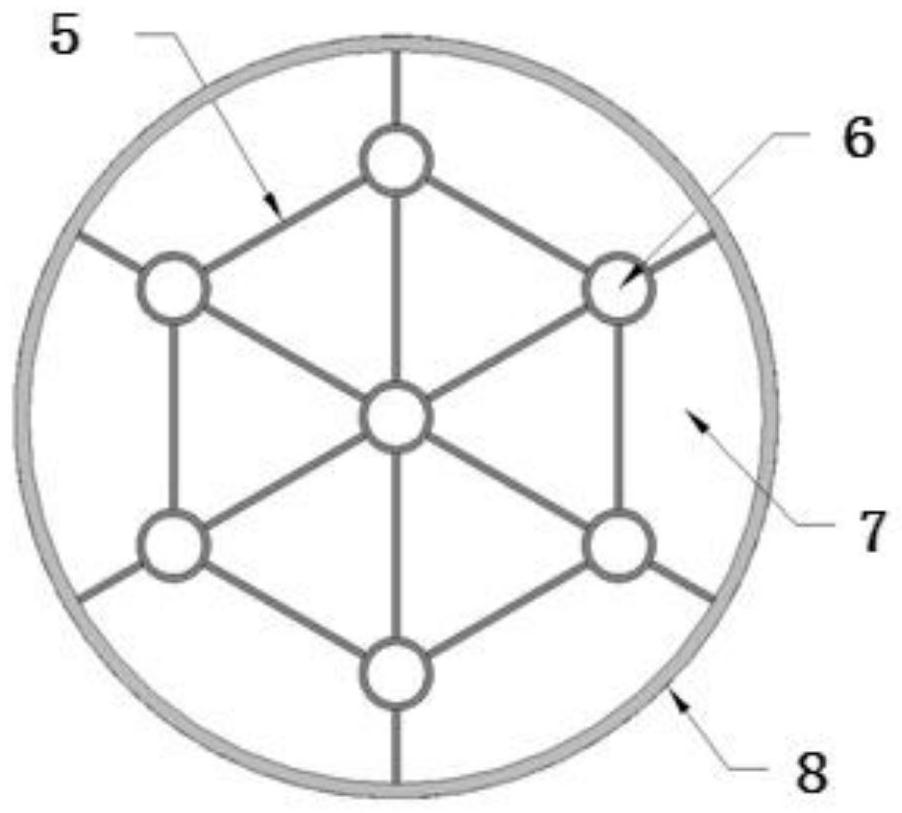

[0105] Design goal: a heat exchanger with an irregular cross-section (different from the circular cross-section in Example 1, which is more general).

[0106] Design conditions: the total temperature at the air inlet of the cooling device is 1000K, the static pressure is 1.3atm, and the gas velocity Mach number at the inlet is 0.4; the equivalent Mach number along the air flow, that is, the gas velocity Mach number in the heat exchange structure is 0.6 (considering heat transfer efficiency and pressure drop constraints).

[0107] Design results: According to the equal Mach number design method of the present invention, it can be calculated that the proportion of air passages on each section of the heat exchange structure in the air precooler is 75%, and the proportion of solids is correspondingly 25%.

[0108] The dimensions of the cooling device corresponding to different flow rates are shown in Table 4:

[0109] Table 4 Size and mass prediction of cooling device (design wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com