Automatic production line for veneer plywood

An automatic production line, plywood technology, applied in the direction of plywood press, veneer press, wood veneer joining, etc., can solve the problems of poor processing efficiency, lack of integral design of production line, poor molding effect, etc., to improve processing Efficiency and forming effect, easy processing forming and stacking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments.

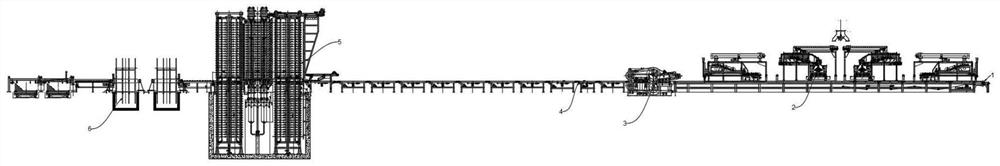

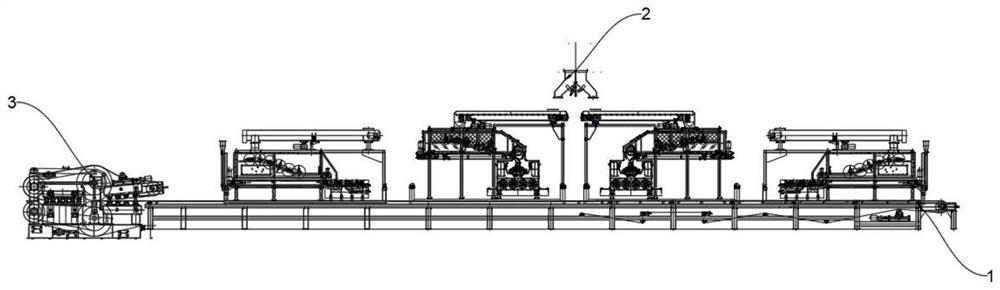

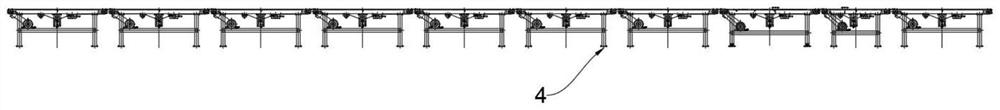

[0019] see Figure 1-4 , an automatic production line for veneerable plywood, including a pretreatment feeding module 1, an auxiliary assembly module 2, a continuous pre-pressing machine 3, a conveying module 4, a pressing machine module 5 and a stacking processing module 6. One end of the pretreatment feeding module 1 An auxiliary assembly module 2 is provided, the other end of the auxiliary assembly module 2 is provided with a continuous pre-pressing machine 3, the other end of the continuous pre-compressing machine 3 is provided with a conveying module 4, and the other end of the conveying module 4 is provided with a pressing machine modu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap