Automatic bag arranging and bundling equipment

A technology for automatic sorting and bagging, which can be used in automatic control of packaging, bundling materials, and parts of bundling machinery, etc., which can solve the problems of high labor intensity and low work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

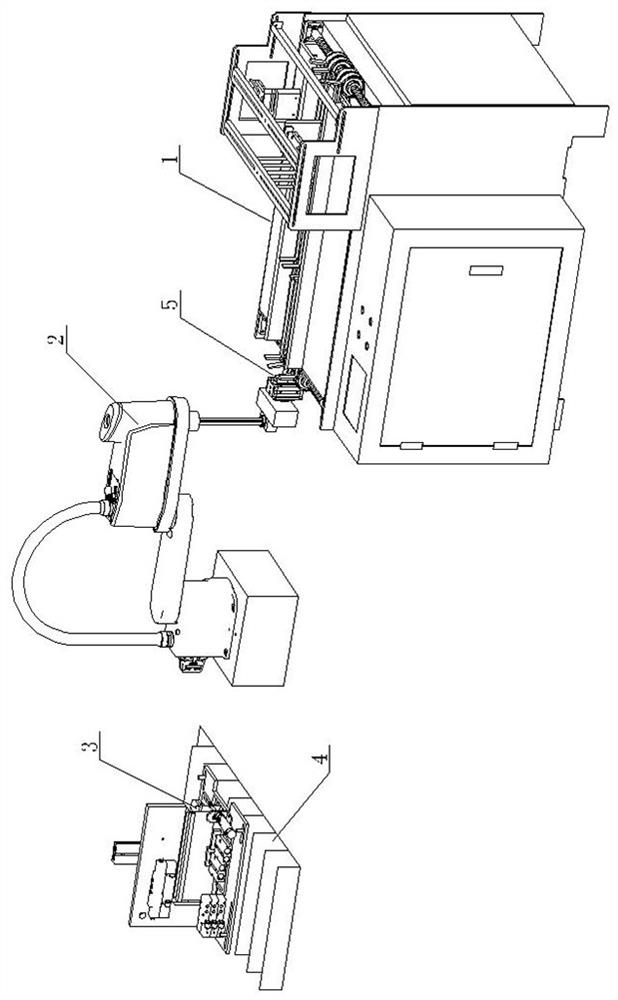

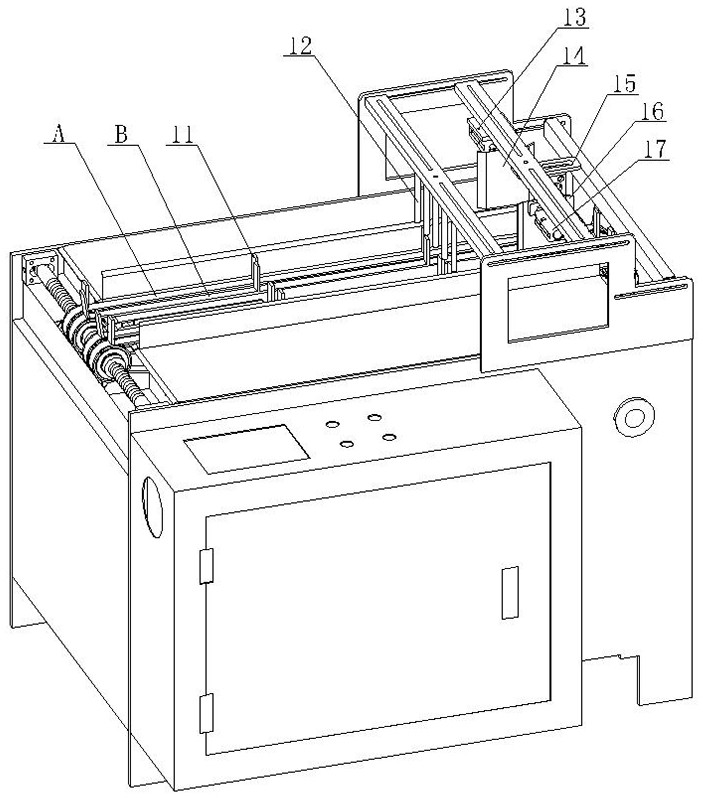

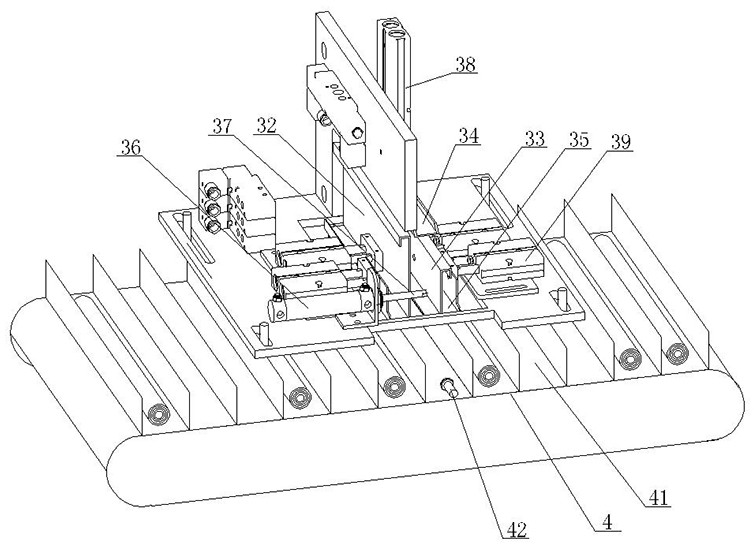

[0019] As shown in the figure, the automatic bag sorting equipment of the present invention is composed of a bag-arranging conveying mechanism 1, a manipulator 2, a bag-bundling forming mechanism 3 and a bag-bundling conveying belt 4. The bag-arranging conveying mechanism 1 is used for stacking and arranging bags. Conveying, bag sorting and conveying mechanism 1 includes four conveyor belts arranged side by side, the two outer conveyor belts A are driven by the first servo motor, the middle two conveyor belts B are driven by the second servo motor, and the conveyor belts A and B are equidistantly arranged. The block 11, the front block 12 and the left and right side blocks are arranged above the input end of the conveyor belt, the left block 16 is connected with the left leveling cylinder 17, the right block 14 is connected with the right leveling cylinder 13, and the position near the side block is provided with The second inductive switch 15; the manipulator 2 moves between t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap