A crane power assembly

A technology of power components and cranes, which is applied to transmission parts, transmission devices, running mechanisms, etc., can solve the problems of large size of the running mechanism, and achieve the effects of compact structure, improved circulation flow, and reliable heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In the following, the present invention will be explained in detail with the implementation examples. It should be noted that in the case of non -conflict, the embodiments and the characteristics in the embodiments in the present invention can be combined with each other.

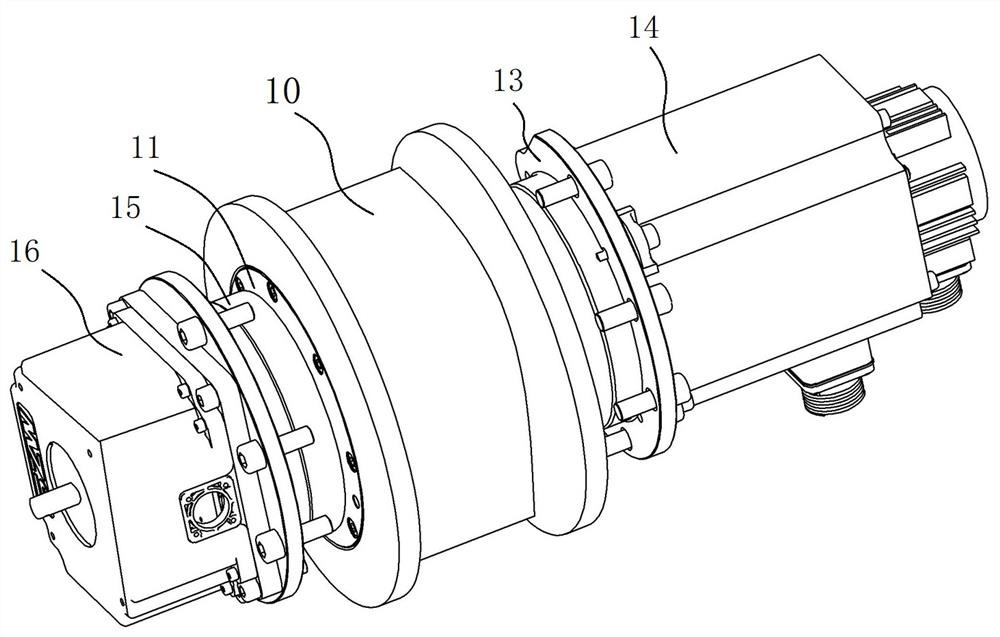

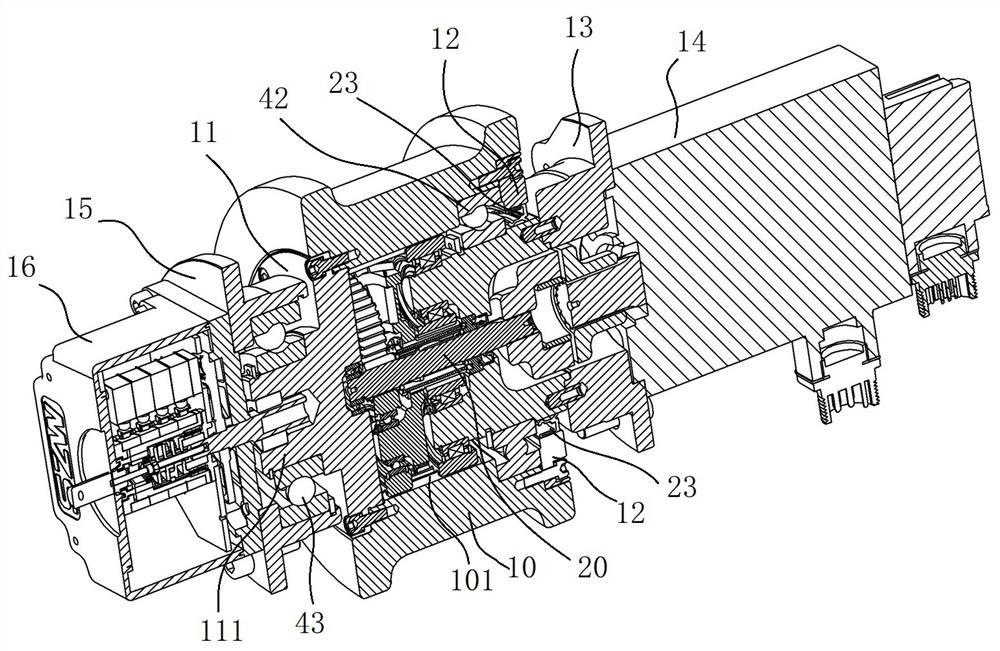

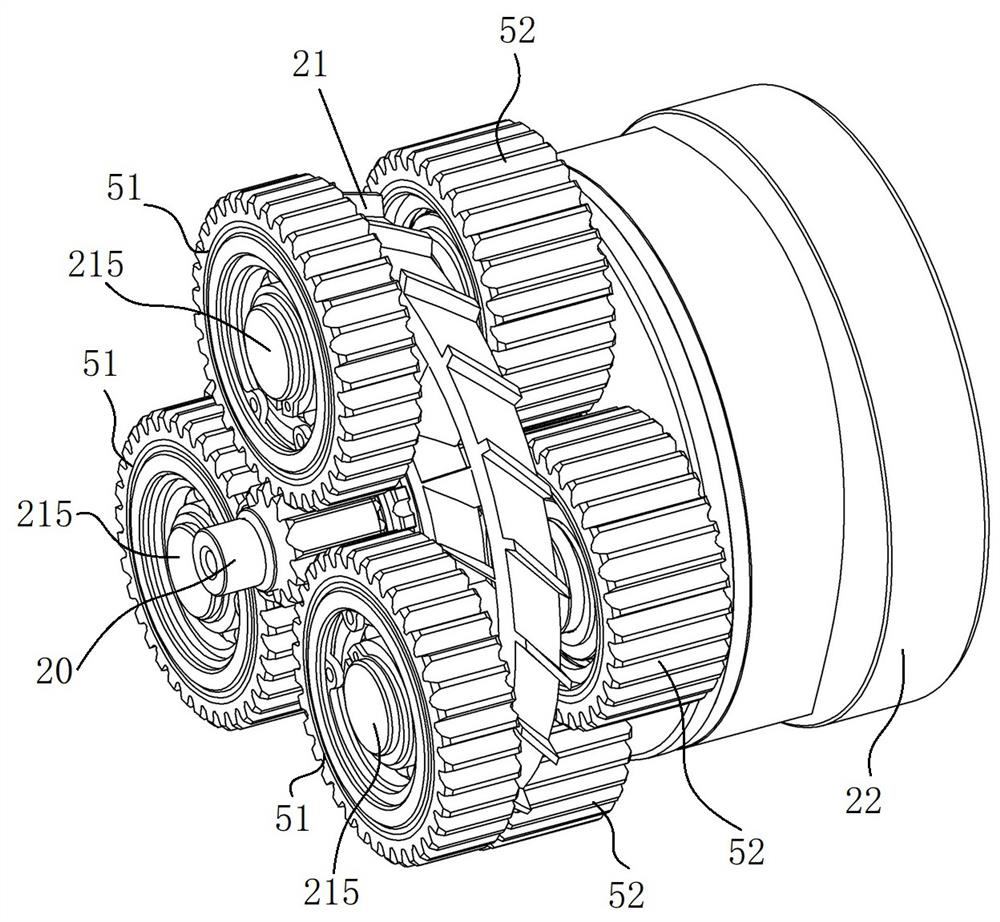

[0029] like Figure 1 to Figure 6 In an embodiment of the beeper power component of the present invention, the crane power component of the embodiment includes a cylindrical wheel 10, and a circular axial sealed end cover 11 on one side of the wheel 10, and the wheel 10 of the wheel 10. On the other side, a shaft block 12 is fixed on the other side. The inner surface of the wheel 10 has an inner gear 101, and the wheel 10 interior is equipped with a planet deceleration module. 21. Second -level planetary rack 22, first -level solar wheel 31 and secondary solar wheel 32, first -class planetary frame 21, and second -level planets on the planet wheels with the inner gear 101 of the wheel 10; One end can be r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com