Nanometer material modified plastic and preparation method thereof

A nanomaterial and plastic technology, applied in the field of plastic processing, can solve the problems of blurred glass and inability to see the working conditions of drying equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A nanomaterial-modified plastic, comprising the following raw materials in parts by weight: 88 parts of polymethyl methacrylate; 79 parts of polycarbonate; 7 parts of isocyanate; 3 parts of phthalate; 30 parts of olefin copolymer elasticity; 17 parts of heat-resistant polyamide resin; 14 parts of polyimide fiber; 13 parts of high temperature resistant adhesive.

[0042] By heating the plastic made with this formula, observe at what temperature the plastic begins to melt.

Embodiment 2

[0044] A nanomaterial-modified plastic, comprising the following raw materials in parts by weight: 100 parts of polymethyl methacrylate; 85 parts of polycarbonate; 10 parts of isocyanate; 6 parts of phthalate; 35 parts of olefin copolymer elasticity; 23 parts of heat-resistant polyamide resin; 21 parts of polyimide fiber; 17 parts of high temperature resistant adhesive.

[0045] By heating the plastic made with this formula, observe at what temperature the plastic begins to melt.

Embodiment 3

[0047] A nanomaterial-modified plastic, comprising the following raw materials in parts by weight: 111 parts of polymethyl methacrylate; 89 parts of polycarbonate; 14 parts of isocyanate; 9 parts of phthalate; 39 parts of olefin copolymer elasticity; 28 parts of heat-resistant polyamide resin; 26 parts of polyimide fiber; 21 parts of high temperature resistant adhesive.

[0048] By heating the plastic made with this formula, observe at what temperature the plastic begins to melt.

[0049] Table I

[0050] temperature Example 1 Example 2 Embodiment 3 254℃ melt not melted melt 278℃ melt not melted melt 264℃ melt not melted not melted

[0051] According to the above examples, the important proportions in Example 2 are the best, and the plastics of this formula have the best heat-resistance effect.

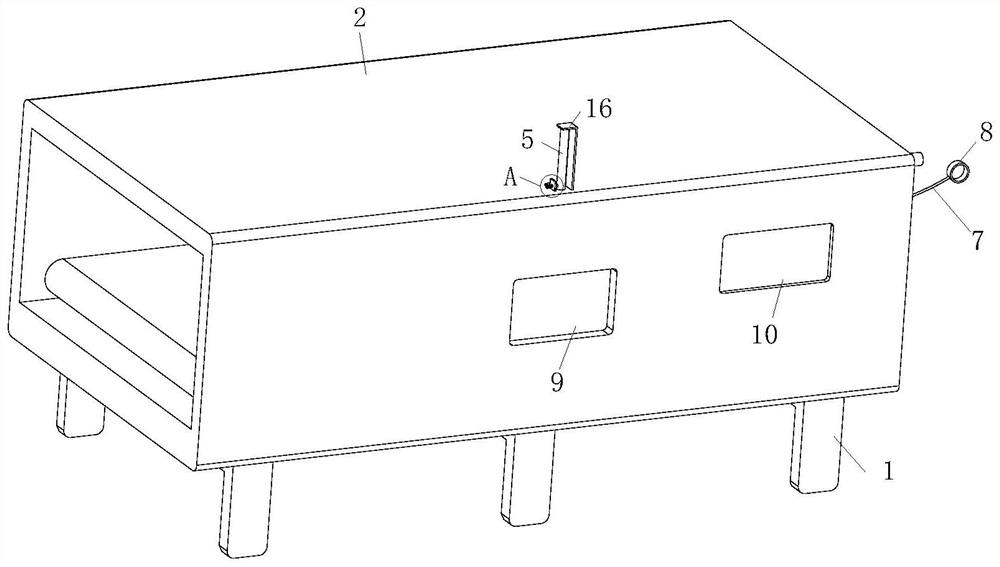

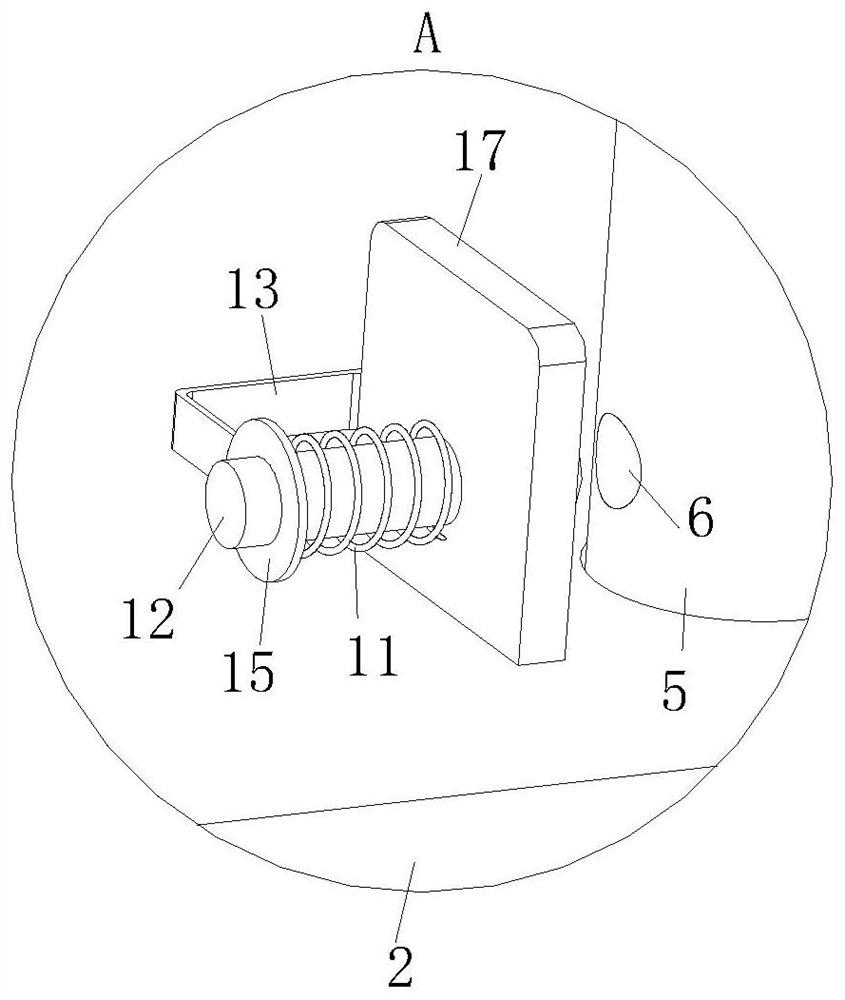

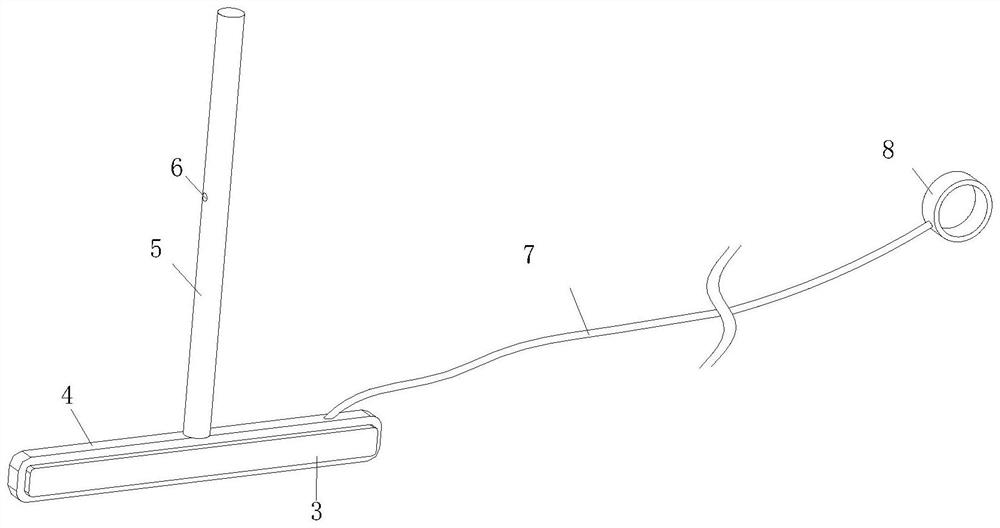

[0052] see Figure 1-5 shown, including the following raw materials by weight:

[0053] 88-111 parts of polymethyl methacrylate;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com