Belt power-assisted sampler

A sampler and belt technology, which is applied in the field of belt-assisted samplers, can solve the problems of high sampling cost, potential safety hazards of electric leakage, and high maintenance costs, and achieve the effects of reducing maintenance costs, reducing sampling costs, and avoiding consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

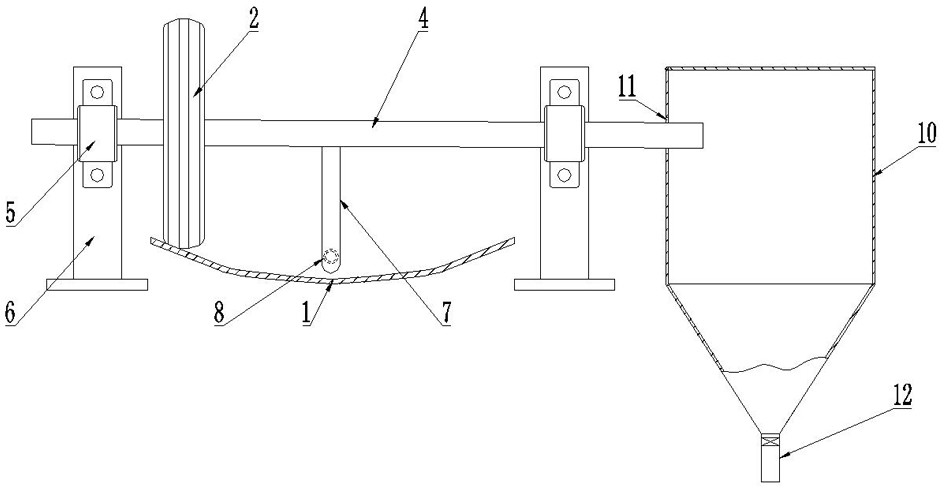

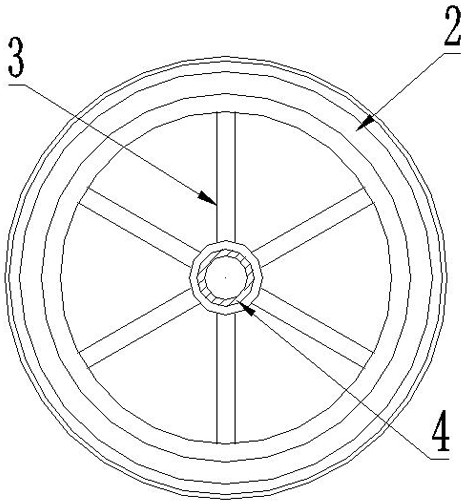

[0026] like Figure 1-Figure 4 Commonly shown, the present invention provides a belt-assisted sampler, comprising a transmission wheel 2, the bottom of the transmission wheel 2 is in contact with the upper edge of the belt 1, and the belt 1 drives the transmission wheel 2 to rotate through friction during movement.

[0027] The inside of the transmission wheel 2 is provided with a diversion oblique tube 4, and the transmission wheel 2 and the diversion oblique tube 4 are connected by a plurality of struts 3 evenly distributed around the circumference; The rod 3 and the transmission wheel 2 rotate synchronously.

[0028] The transmission wheel 2 can be a tire.

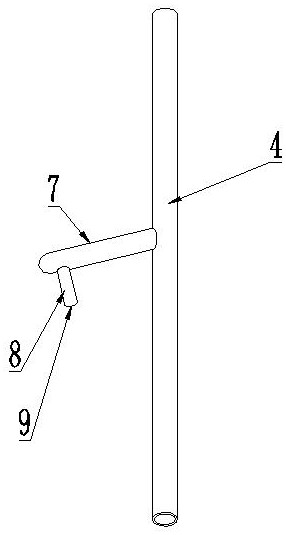

[0029] The diversion oblique tube 4 is located above the belt 1, and the two ends of the diversion oblique tube 4 are respectively penetrated in the bearing seat 5, and the bearing seat 5 rotates and supports the diversion oblique tube 4; the bearing seat 5 is respectively connected by bolts. Mounted on the support 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com