Method for monitoring frictional wear state by using frictional electric signal

A friction and wear, electrical signal technology, applied in the field of friction, can solve the problems of damage, poor sensitivity and wear of the two friction surfaces of the friction pair, and achieve the effect of easy installation, sensitive response, and dynamic monitoring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

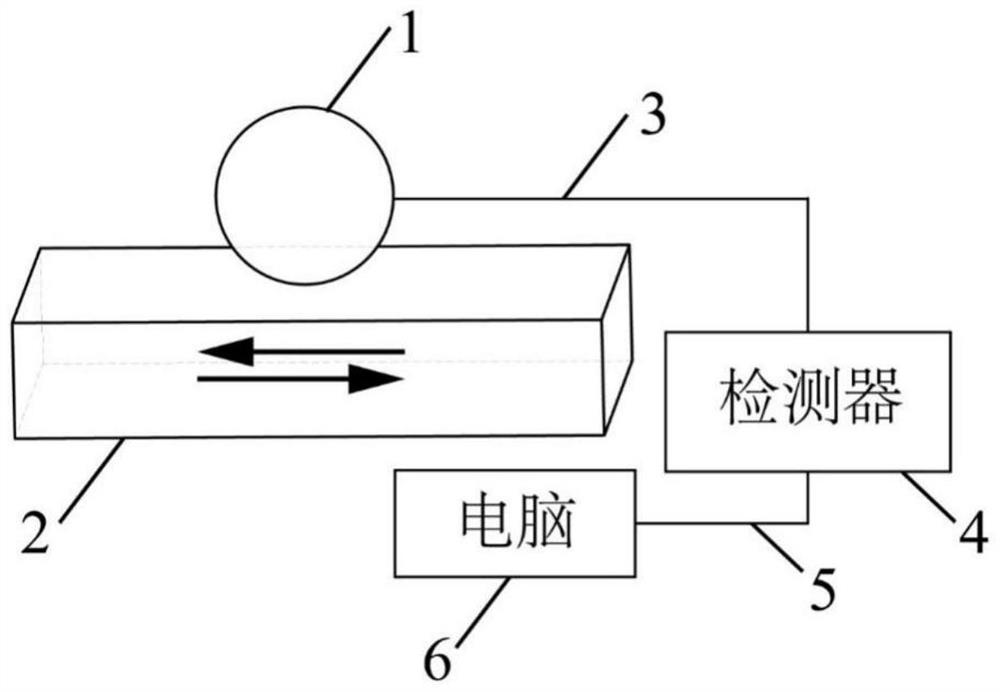

[0060] Real-time monitoring of friction and wear status of rolling bearings. Rolling bearings are composed of rolling elements, outer rings and inner rings. The materials of rolling elements, outer rings and inner rings are high carbon bearing steel (GCr15). The rolling bearings are lubricated with liquid lubricants. friction movement. The monitoring device is connected as Figures 7 to 8 As shown, one end of the wire 3 is connected to the outer ring, and the other end is connected to a current amplifier, and the current amplifier transmits the triboelectric signal to the computer 6 through the data cable 5 .

[0061] The detected triboelectric signals such as Figure 9 shown. Figure 9 The dotted box 1 is the triboelectric signal under normal friction and lubrication conditions of the friction pair, which is 50nA, and the triboelectric signal of the friction pair in the dotted box 2 is slightly worn. It can be seen that discharge will occur at this time, and the current dur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com