Embedded system-oriented flotation froth flow velocity extraction method

An embedded system and extraction method technology, applied in the field of froth flotation automation, can solve problems such as increasing the cost of manual observation, inaccuracy, and difficulty in archiving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

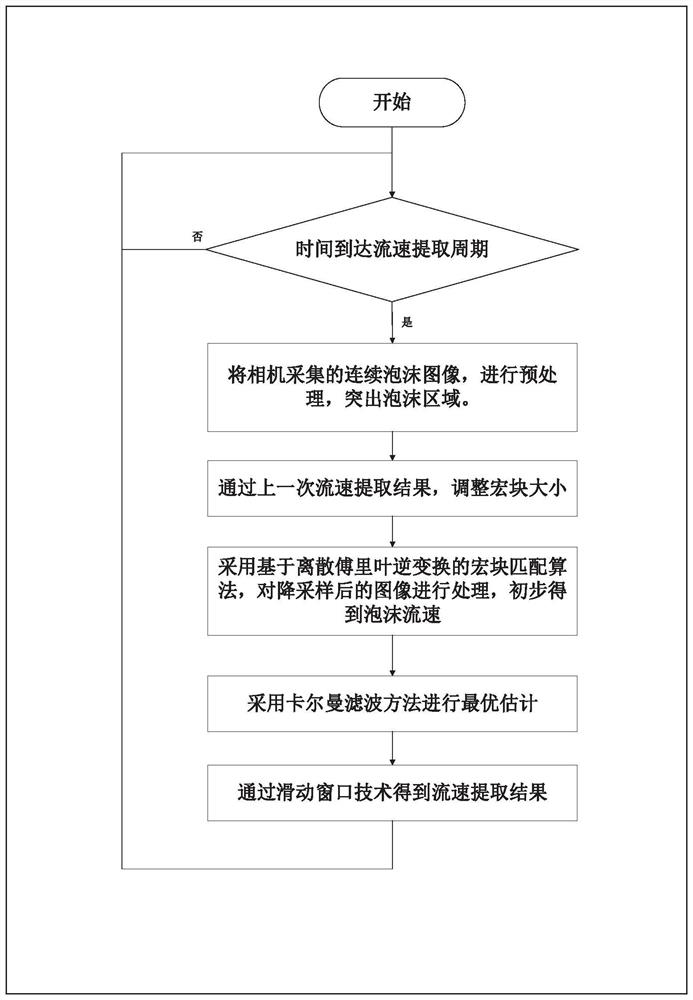

[0069] see figure 1 , the present embodiment discloses a method for extracting the flow rate of flotation froth for an embedded system, including:

[0070] Acquire flotation froth images for a period of time, perform image preprocessing, and obtain image sets with prominent froth areas;

[0071] The image set is down-sampled, the size of the macroblock is adjusted according to the result of the last flow velocity extraction, and the macroblock matching algorithm based on the inverse discrete Fourier transform is used to initially obtain the foam flow velocity;

[0072] After Kalman filtering, the extraction flow rate is obtained by sliding window technique.

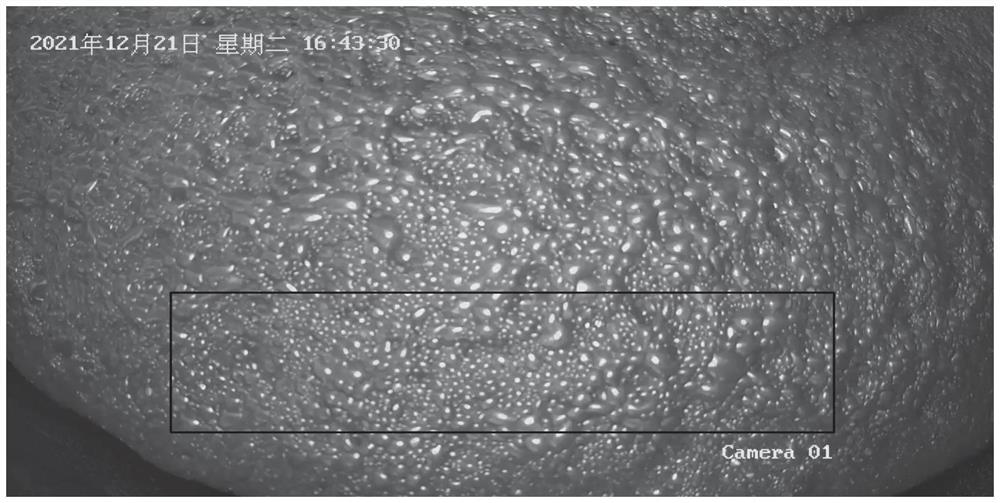

[0073] Specifically, the foam image of a tin ore processing plant for a certain period of time is used as a case for analysis. First of all, at the industrial site of a tin ore dressing plant, a camera is placed above the flotation cell to capture the image of the foam layer on the surface of the flotation cell. The for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com