Variable air volume adjusting method and device for exhaust hood of laboratory

An adjustment method and an adjustment device technology, which are applied in chemical instruments and methods, cleaning methods and appliances, special data processing applications, etc., can solve the problem of low precision of variable air volume adjustment in the fume hood, complex structure of the air volume adjustment system in the fume hood, etc. Problems, to avoid pressure rebound fluctuations, improve pressure irrelevance, and strong practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

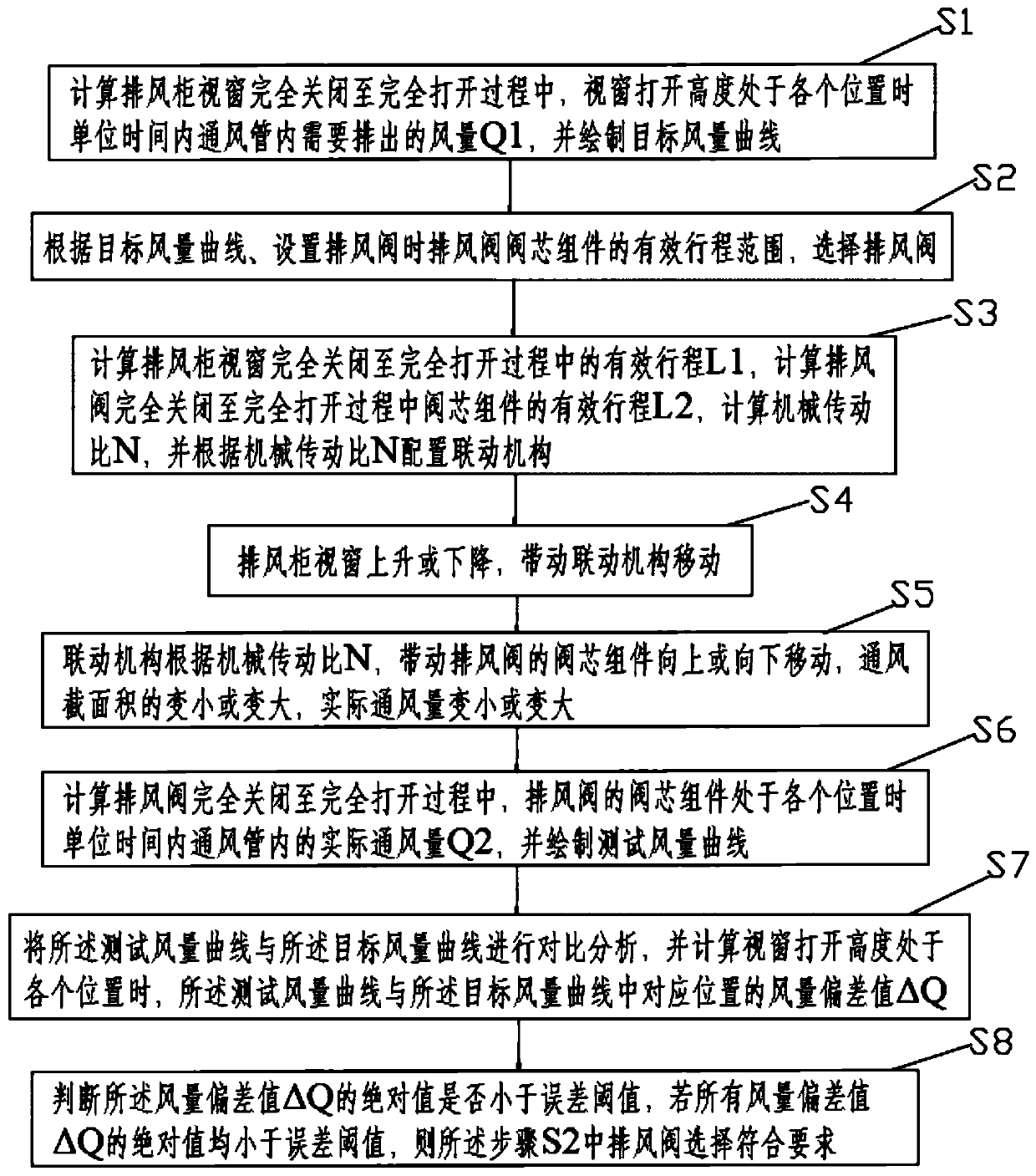

[0047] Please refer to Figure 1-Figure 3 , the invention provides a method for adjusting the variable air volume of a laboratory fume hood, comprising the following steps:

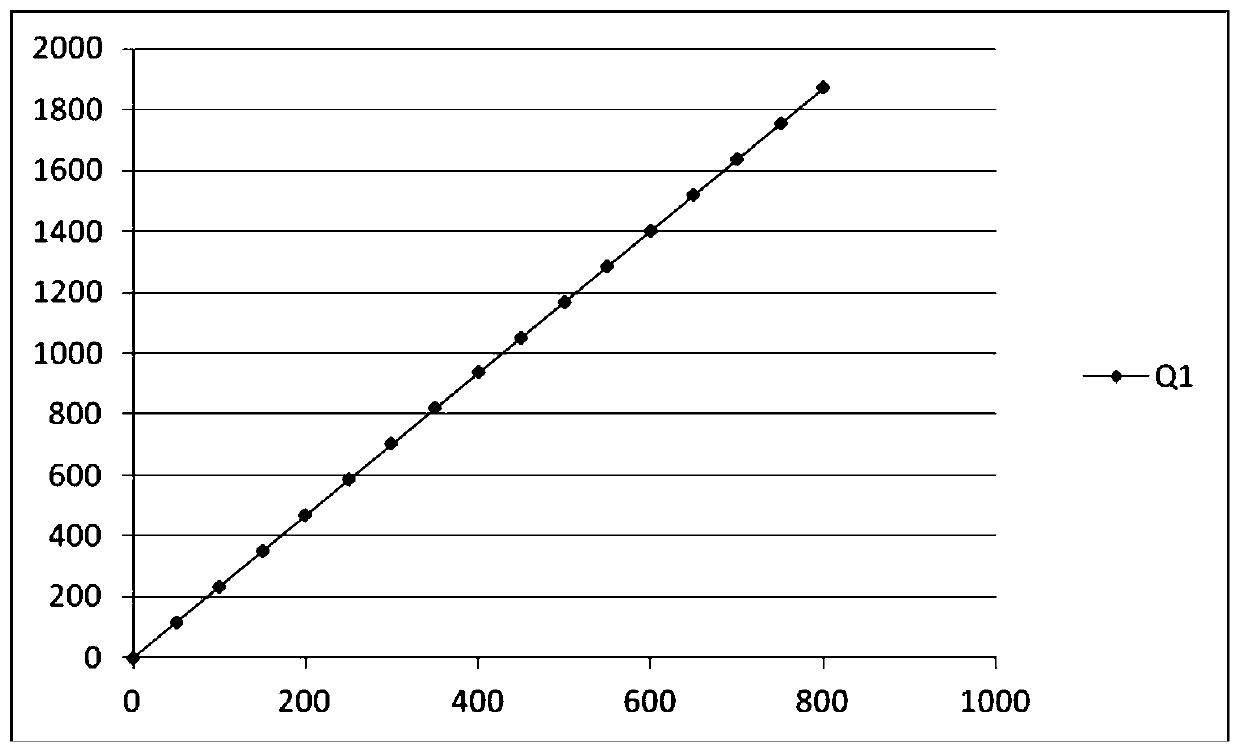

[0048] S1: The effective height and effective width of the fume hood are 800mm and 1300mm respectively, and the surface wind speed is 0.5m / s. When calculating the window height of the fume hood from 0mm to the window height of 800mm, each position needs to be exhausted in the ventilation pipe every hour. The air volume Q1 (refer to Table 1 for details), and draw the target air volume curve, such as figure 2 .

[0049] The air volume Q1=effective width of the window×opening height of the window×surface wind speed×unit time.

[0050] Specifically, in the present invention, the surface wind speed is 0.5m / s.

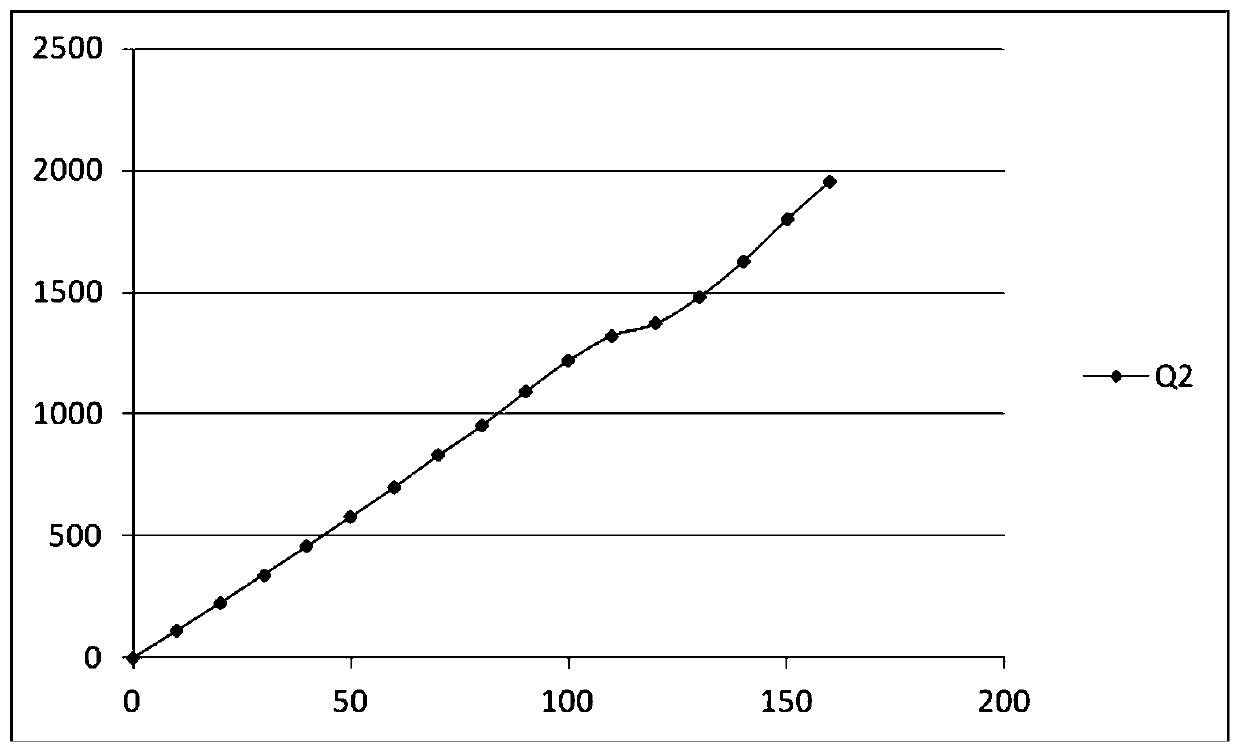

[0051] S2: Select the exhaust valve according to the target ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com