Wafer ring taking and mounting device and wafer ring taking and mounting method

A technology of wafer ring and material sticking, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., and can solve the problems of low labor efficiency and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The present invention will be described in further detail below in conjunction with the accompanying drawings.

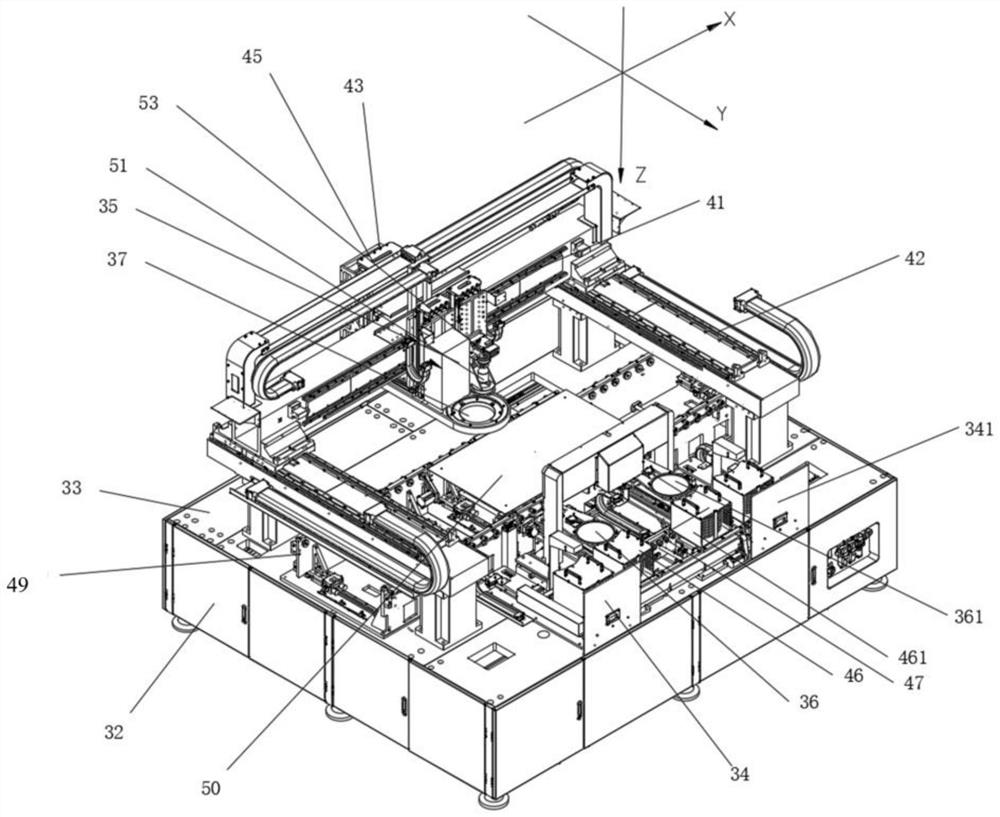

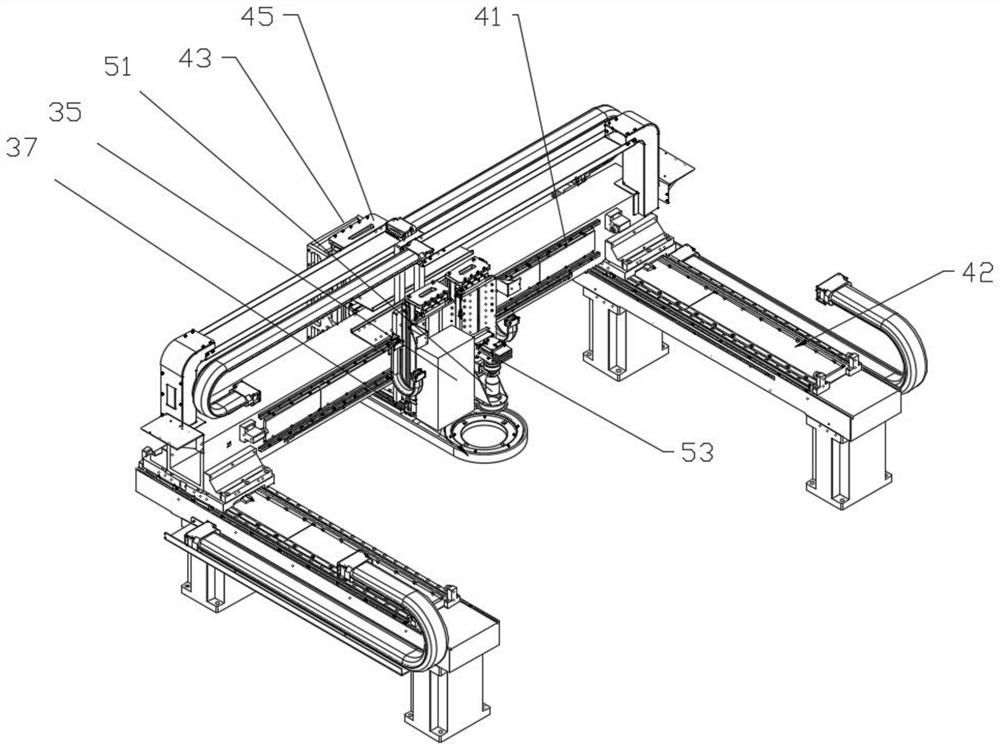

[0075] The present invention will be described in further detail below in conjunction with the accompanying drawings. figure 1 The coordinate indications in determine the directions of the X-axis, Y-axis and Z-axis mentioned in the present invention.

[0076] like Figures 1 to 5 As shown, a wafer ring pick-and-place device includes:

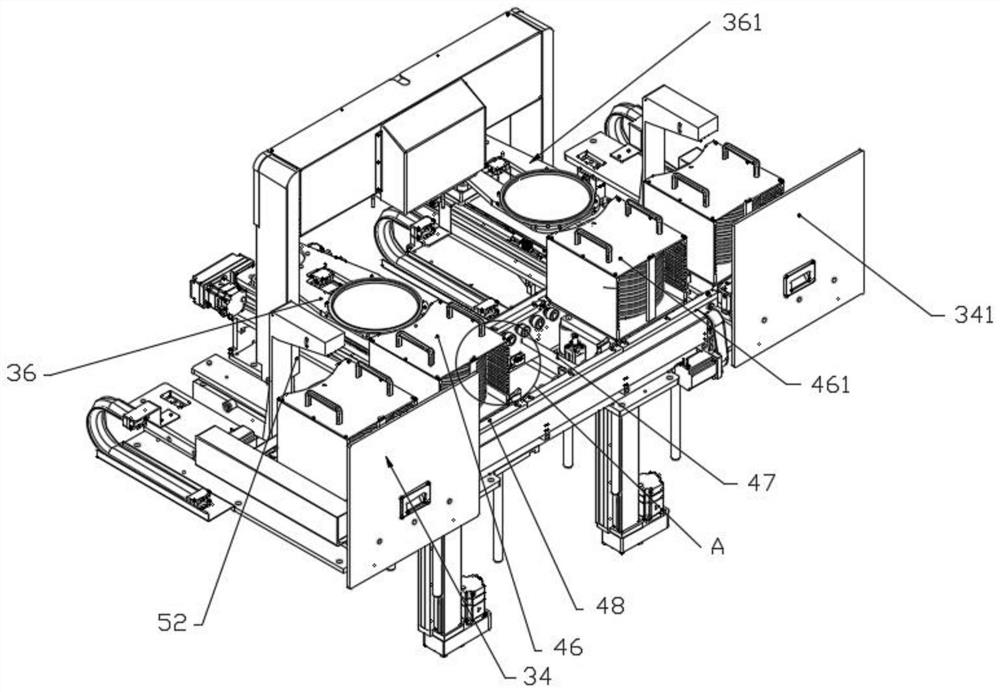

[0077] a material storage assembly 34 for placing the wafer ring 21;

[0078] The front-stage reclaiming mechanism 36 is used to take out the wafer ring 21 in the material storage assembly 34 and transfer it to the transfer reclaiming station;

[0079] The rear-stage reclaiming mechanism 37 is used to transfer the wafer ring 21 transferred by the front-stage reclaiming mechanism 36 on the transfer reclaiming station to the placement station;

[0080] Mounting component 35, the mounting component 35 has a mounting work part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com