Anti-adhesion material

An anti-adhesion, polymer technology, applied in the direction of drug combination, bandage, surgery, etc., can solve the problems of fever and inflammation, achieve excellent biodegradability, inhibit the onset of complications, sufficient strength and handling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

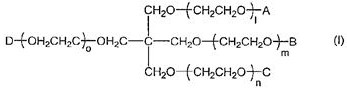

[0116] A four-branched polyethylene glycol derivative (pentaerythritol polyethylene glycol, SUNBRIGHT (registered trademark) PTE-10T, manufactured by NOF Corporation) (hereinafter, this four-branched polyethylene glycol derivative is referred to as "" Each terminal hydroxyl group of 4PEG") was polymerized with L-lactide (PURASORB (registered trademark) L, manufactured by Corbion) to synthesize a 4PEG-PLLA block copolymer, which was obtained by 1 H-NMR (apparatus name: EX-270, measurement frequency: 400 MHz, measurement solvent: deuterated chloroform, number of counts: 8, measurement temperature: room temperature (about 25°C)), the molecular weight of PTE-10T is assumed to be 10,000 The calculated number average molecular weight was about 40,000. The obtained 4PEG-PLLA had the structures represented by the following general formulae (I) and (II).

[0117] [Chemical 13]

[0118]

[0119] Here, in formula (I), l, m, n and o are each independently an integer of 50 to 60, and ...

Embodiment 2

[0127] Each terminal hydroxyl group of 4PEG (SUNBRIGHT (registered trademark) PTE-10T, manufactured by NOF Corporation) was mixed with L-lactide (PURASORB (registered trademark) L, manufactured by Corbion) and glycolide (PURASORB (registered trademark) G , Corbion Corporation) random polymerization to synthesize 4PEG-PLGA block copolymer, the 4PEG-PLGA block copolymer was determined by measuring under the same conditions as in Example 1 1 The number average molecular weight calculated by H-NMR assuming that the molecular weight of PTE-10T was 10,000 was about 46,000. The ratio of the number of moles of lactic acid to the number of moles of glycolic acid, 1.0, was 4.1. The obtained 4PEG-PLGA block copolymer had structures represented by the following general formulae (I) and (III).

[0128] [Chemical 15]

[0129]

[0130] Here, in formula (I), l, m, n and o are each independently an integer of 50 to 60, and A, B, C and D are each independently a group represented by formul...

Embodiment 3

[0136] Each terminal of an 8-branched polyethylene glycol derivative (SUNBRIGHT (registered trademark) HGEO-50H, manufactured by NOF Corporation) (hereinafter, this 8-branched polyethylene glycol derivative is referred to as "8PEG") The hydroxyl group was polymerized with L-lactide (PURASORB (registered trademark) L, manufactured by Corbion Corporation) to synthesize 8PEG-PLLA block copolymer. The 8PEG-PLLA block copolymer was measured under the same conditions as in Example 1. of 1 The number average molecular weight calculated by H-NMR assuming that the molecular weight of HGEO-50H was 5,000 was about 43,000. The obtained 8PEG-PLLA block copolymer had structures represented by the following general formulae (IV) and (II).

[0137] [Chemical 17]

[0138]

[0139] Here, in formula (IV), p, q, r, s, and t are each independently an integer of 10 to 15, u is 4, and A, B, C, D, and E are each independently and in each repeating unit is a group represented by formula (II),

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com