Light equalizing method and device for LCD (liquid crystal display) three-dimensional printing

A technology of 3D printing and LCD screen, which is applied in the field of 3D printing, can solve the problems of collection light intensity and grayscale weakening, poor uniform light effect, inaccurate pixel grayscale collection, etc., to solve the problem of coordinate offset and method ideas Simple and clear, excellent uniform light compensation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

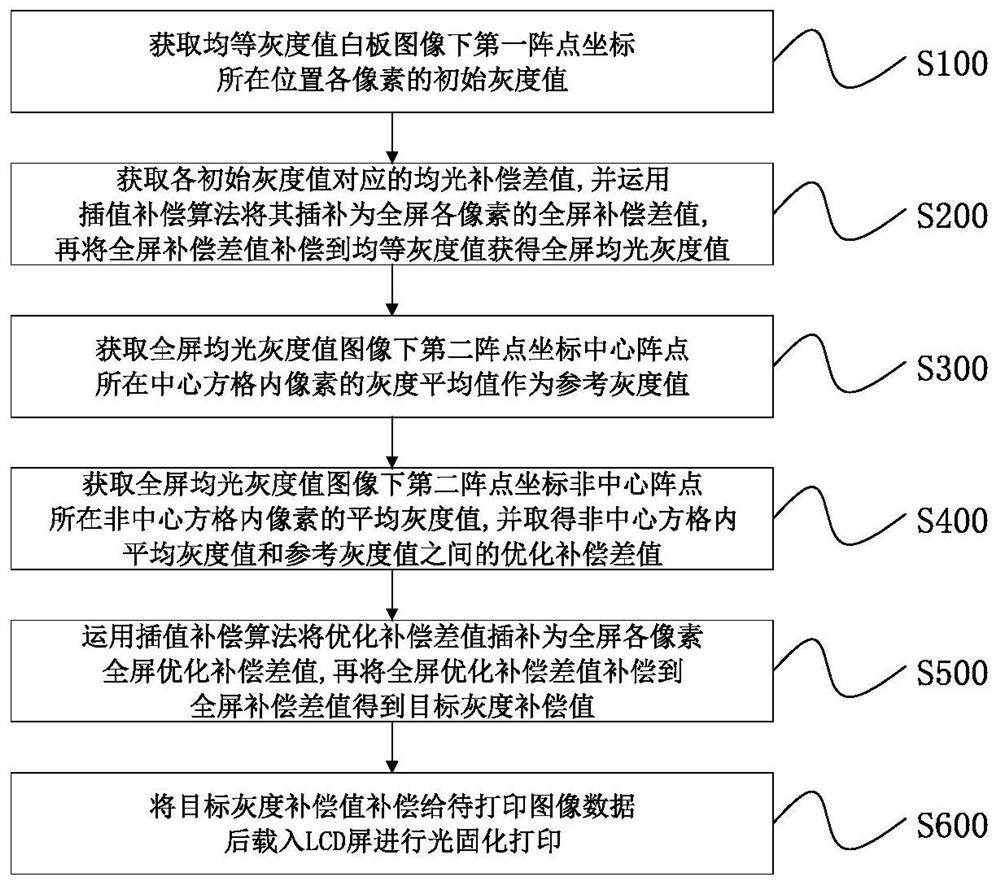

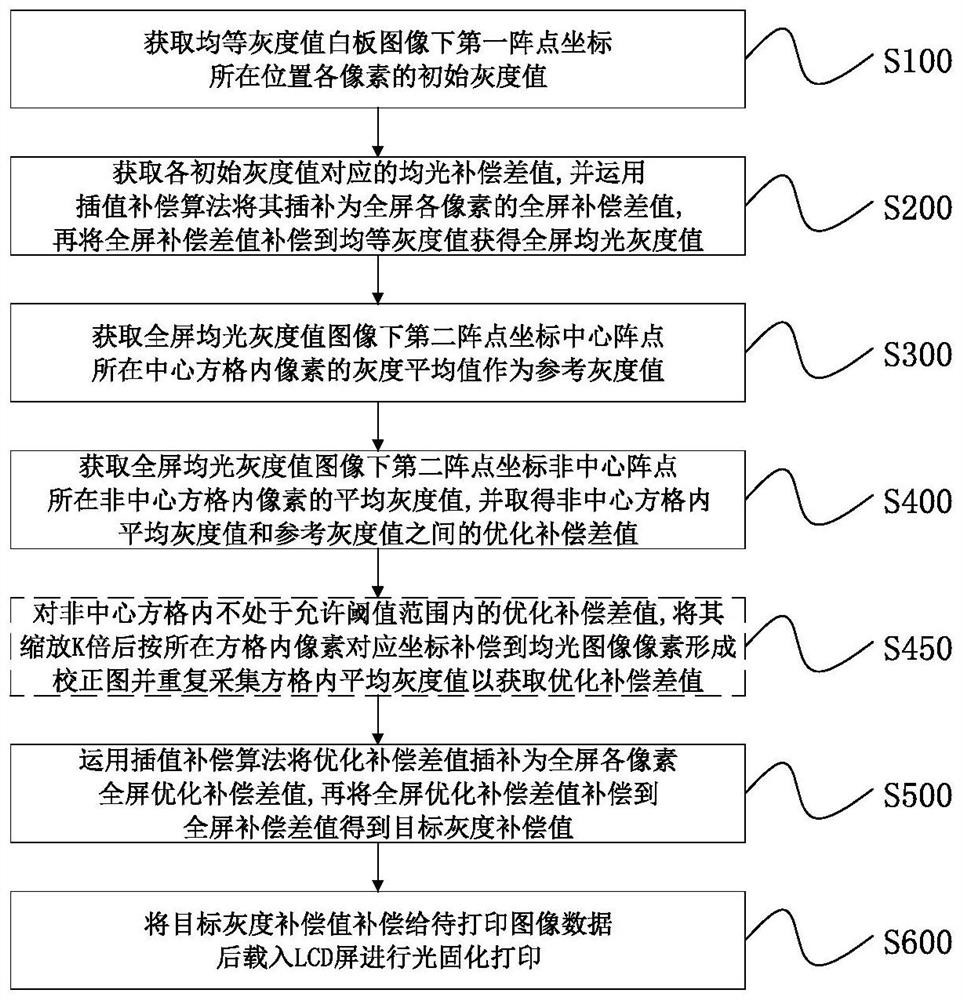

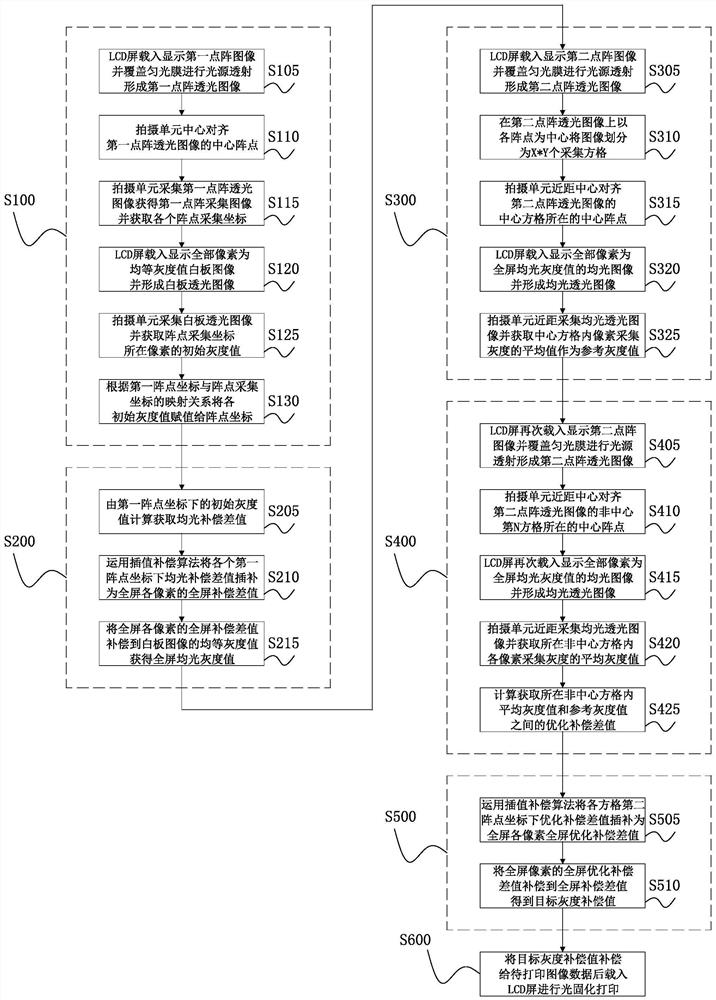

Method used

Image

Examples

Embodiment 3D

[0212] Figure 14A It is a schematic diagram of the principle structure of the 3D printer according to the embodiment of the present invention. As shown in the figure, a 3D printer suitable for the embodiment of the uniform light method of the present invention includes:

[0213] The light source 131 is used for emitting ultraviolet light to transmit the LCD screen and irradiating the liquid tank and the photosensitive resin solution in the photosensitive resin 138 to make it photocurable;

[0214] The LCD screen 132 is used to load and display the to-be-printed image and the to-be-printed image for which the target grayscale compensation value has been compensated, and to mask the ultraviolet light emitted by the light source 131;

[0215] Liquid tank and photosensitive resin 138, wherein the bottom of the liquid tank is light-transmitting, and the photosensitive resin solution is contained in the tank;

[0216] Forming platform and driving mechanism 139, wherein the formin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com