Working cavity structure of hydraulic retarder

A hydraulic retarder and working chamber technology, applied in the direction of liquid resistance brakes, brake types, brake components, etc., can solve the problems of inconvenient fluid inflow and outflow, large space occupation of the working chamber, and inability to reduce fluid resistance, etc. It achieves the effects of easy normal rotation, simple layout and avoiding difficulty in oil discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below with reference to the embodiments and the accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

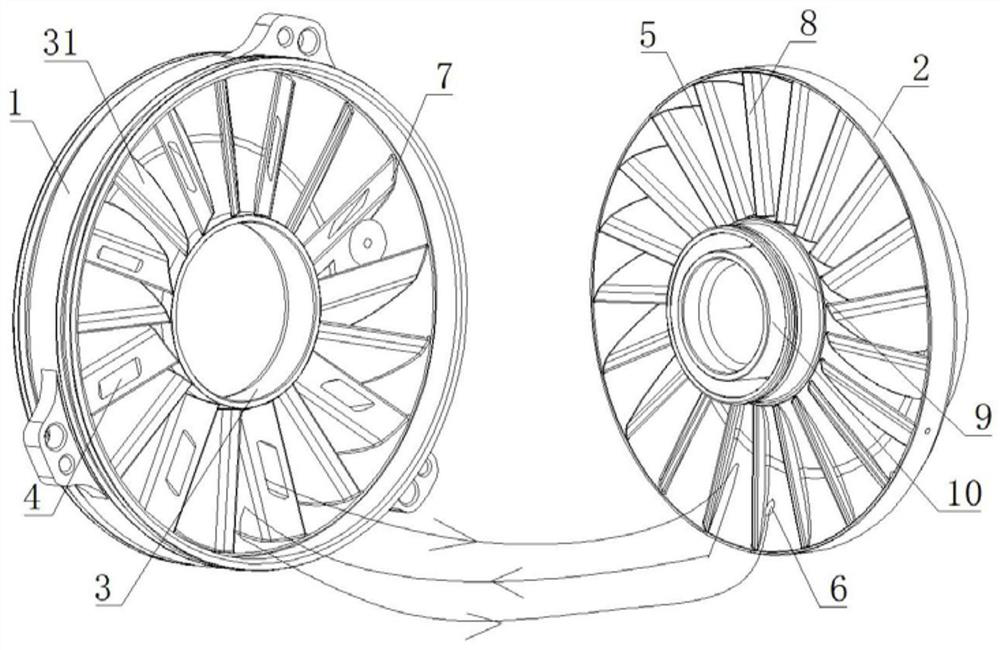

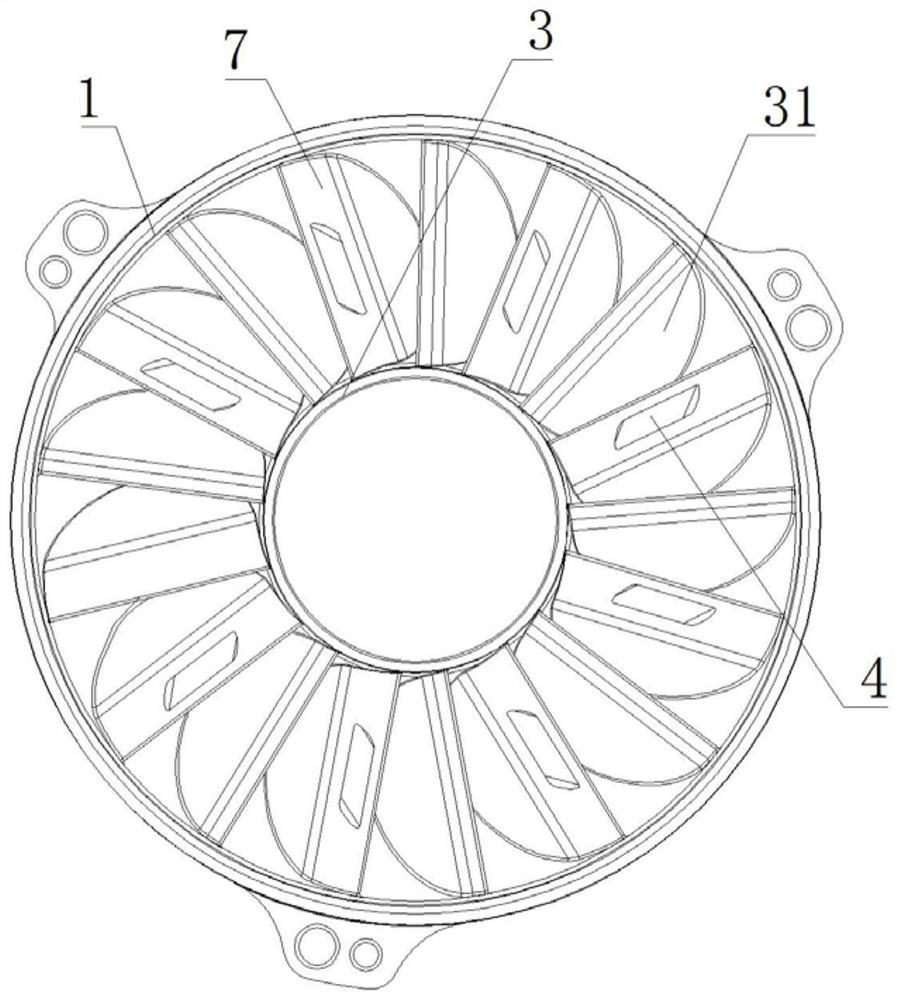

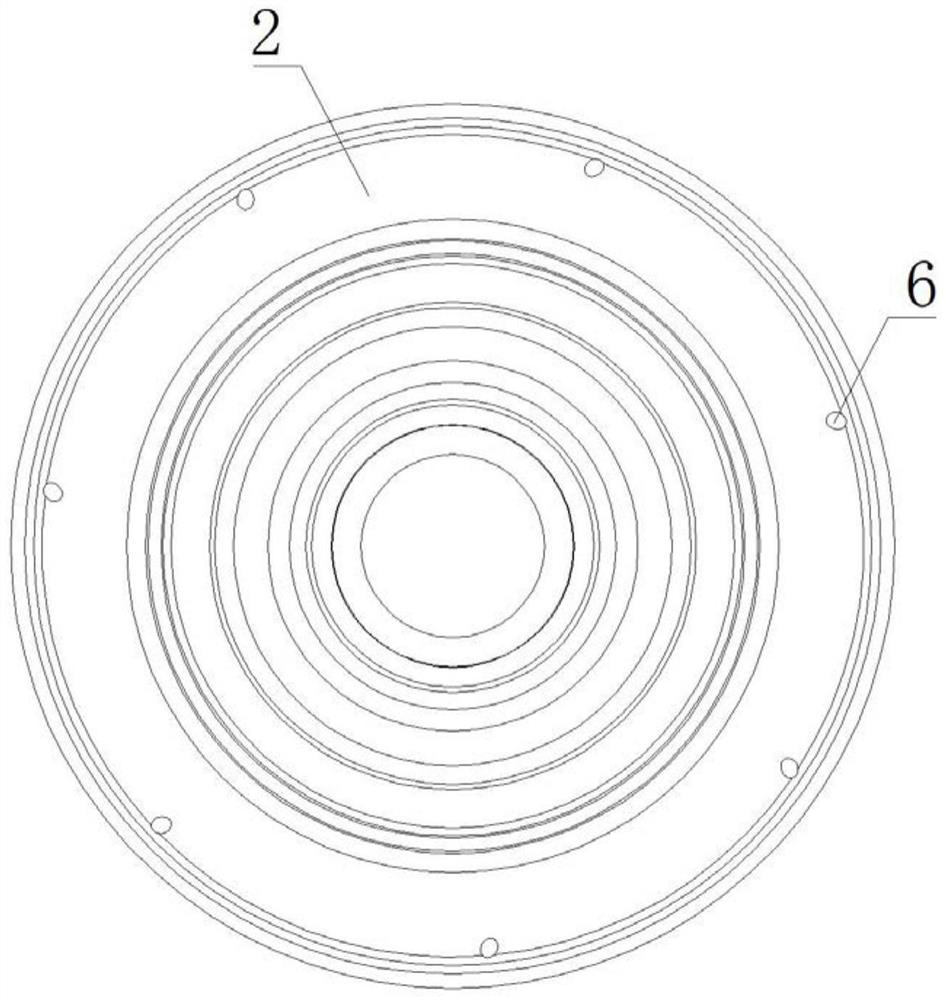

[0026] like Figure 1-3 As shown in the figure, a working cavity structure of a hydraulic retarder includes a first blisk 1 and a second blisk 2 which are both hollow structures, the first blisk 1 and the second blisk 2 are coaxially matched, and the first blisk 1 and the second blisk 2 are coaxially matched. A first impeller 3 is coaxially connected to the disc 1, a first oil port 4 is eccentrically opened on the first impeller 3, a second impeller 5 is coaxially connected to the second leaf disc 2, and the inner wall of the second leaf disc 2 A second oil port 6 is opened in the circumferential direction.

[0027] like Figure 1-3 As shown, in this embodiment, the middle part of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com