Buffering and damping structure based on paper folding principle

A principle, the technology of shock-absorbing cylinder, which is applied in the field of buffering and shock-absorbing structures based on the origami principle, can solve the problems of poor adaptability, difficult installation and movement, low space utilization, etc., and achieves the effect of strong angle tolerance and wide application scenarios.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

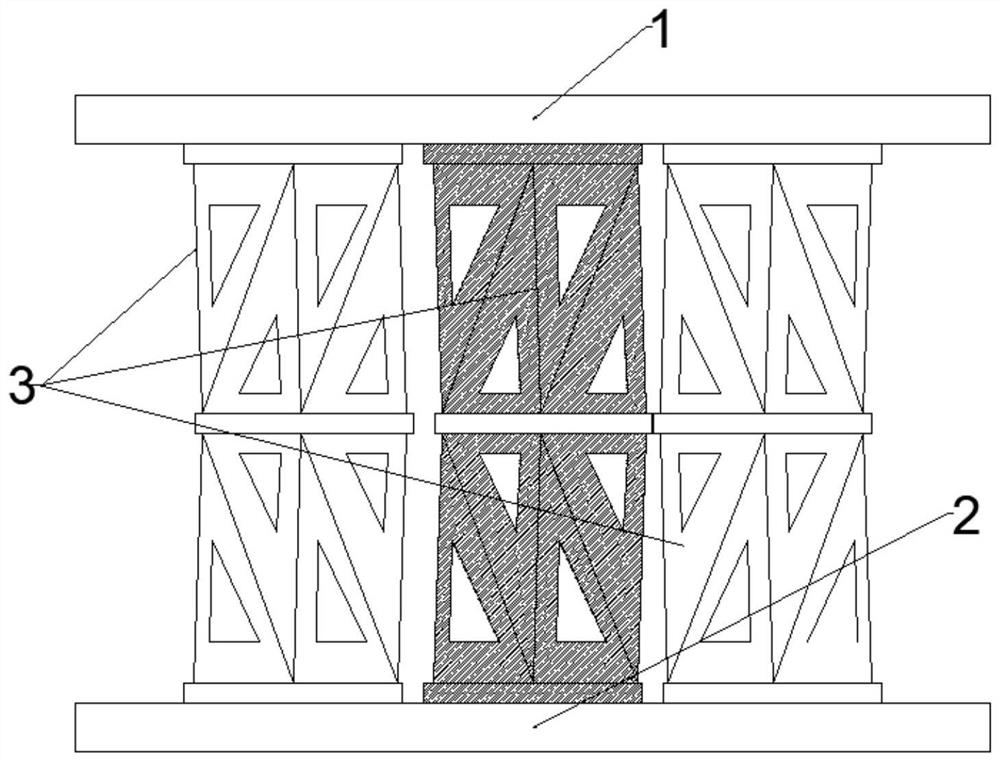

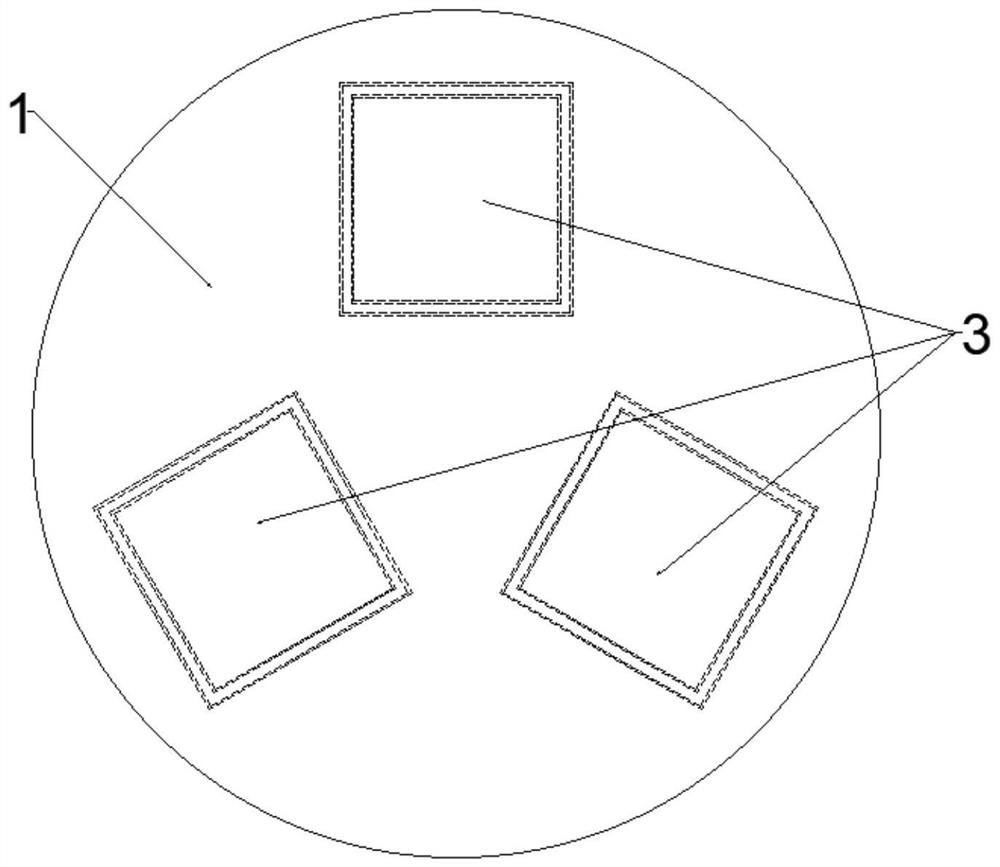

[0043] A cushioning and shock absorbing structure based on the origami principle, such as Figure 1-9 As shown, it includes an upper load-bearing plate 1, a deformation energy-absorbing module, and a base 2. The deformation energy-absorbing module is arranged between the upper load-bearing plate 1 and the base 2. The deformation energy-absorbing module includes three such as The basic module 3 is placed in a triangle with a flexible origami structure.

[0044] In this embodiment, the basic module 3 can be a flexible origami structure of various shapes, and the shock absorption and buffering effect can be realized by the flexible origami structure.

Embodiment 2

[0046]On the basis of embodiment 1, this embodiment is improved as:

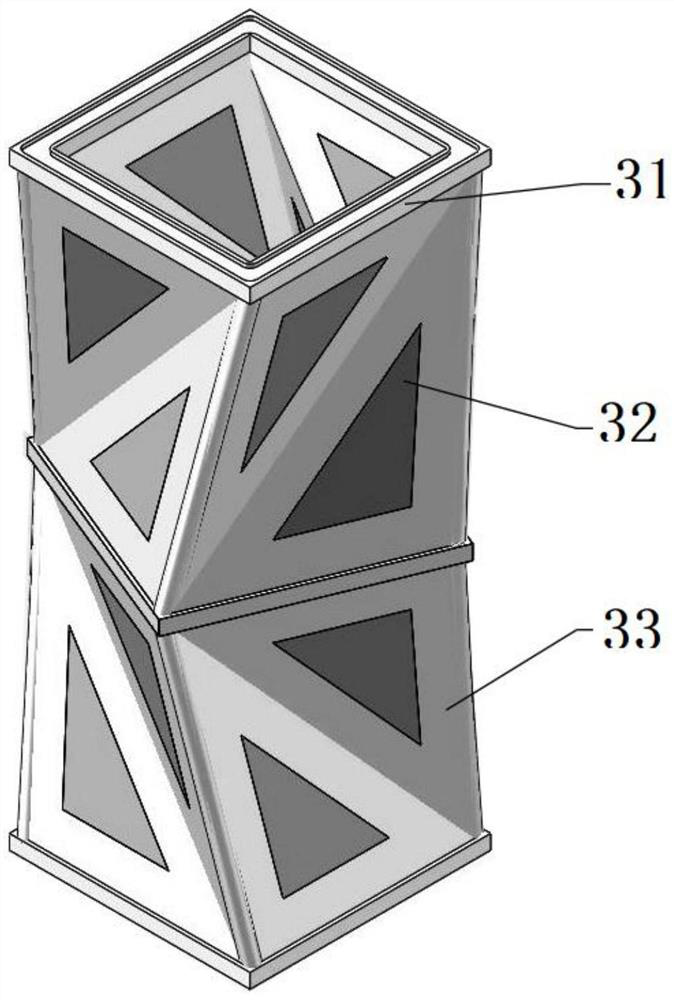

[0047] like Figure 1-9 As shown, the basic module 3 includes 3 fastening and positioning frames 31, 2 deformation energy absorbing films 33, and each deformation energy absorbing film 33 is provided with 8 stability-enhancing and limiting panels 32; The frames 31 are arranged in the up-down direction, and the two deformable energy-absorbing films 33 are formed by origami process to form a buffering and shock-absorbing cylinder with open upper and lower ends. The upper and lower ends of the buffering and shock-absorbing cylinders are respectively fixedly connected to the ends of the corresponding fastening and positioning frames 31 , and the stability-enhancing and limiting panels 32 are fixedly connected to the surface of the deformation energy-absorbing film 33 .

[0048] In this embodiment, the fastening and positioning frame 31 can be set in a square, circular or other shape as required, the buffer and ...

Embodiment 3

[0050] On the basis of embodiment 2, this embodiment is improved as:

[0051] like Figure 1-9 As shown in the figure, the fastening and positioning frame 31 is a regular quadrilateral frame, the deformation energy absorbing film 33 is a parallelogram structure, and the manufacturing method of the buffering and shock absorbing cylinder is: Step A1, the parallelogram structure 2 Each long side is divided into 4 equal parts, and grooves are cut in the inner surface of the deformation energy absorbing film 33 along the connection line of the upper and lower corresponding bisected points, and three first grooves 333 parallel to the sides of the parallelogram structure are formed. At the same time, the parallelogram structure is divided into four smaller parallelogram structures by the first groove 333; in step A2, the outer surface of the deformation energy absorbing film 33 moves along the longer diagonal of the smaller parallelogram structure to dig grooves , and form 4 second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com