Film pressure sensor

A thin-film pressure and sensor technology, applied in the direction of instruments, measuring forces, measuring devices, etc., can solve the problems of small measurement range, inability to install, and cannot be applied to engineering applications, and achieve the effect of improving the reliability of measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present application will be further described below with reference to specific embodiments.

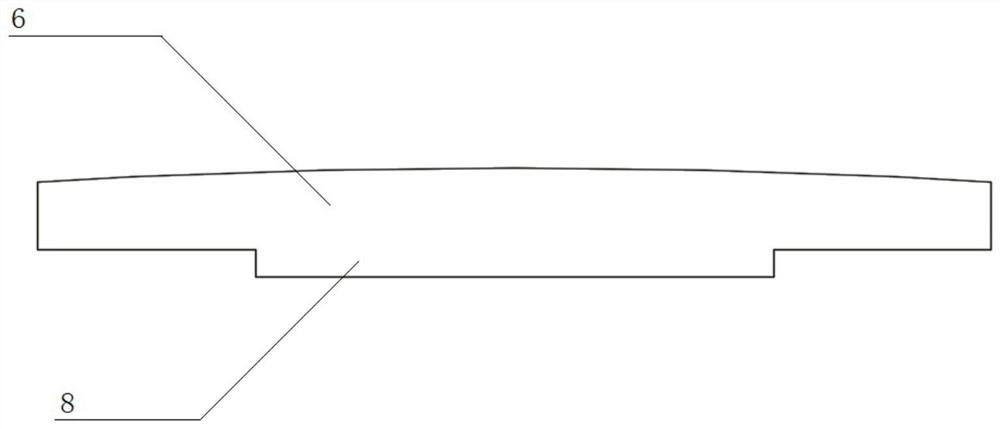

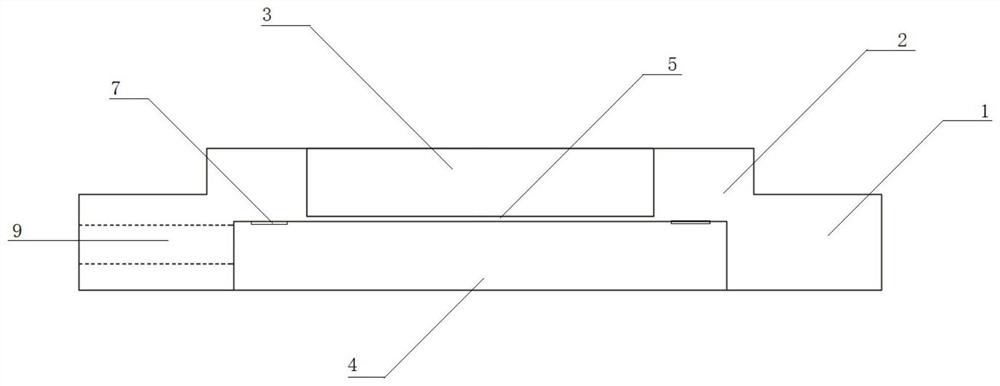

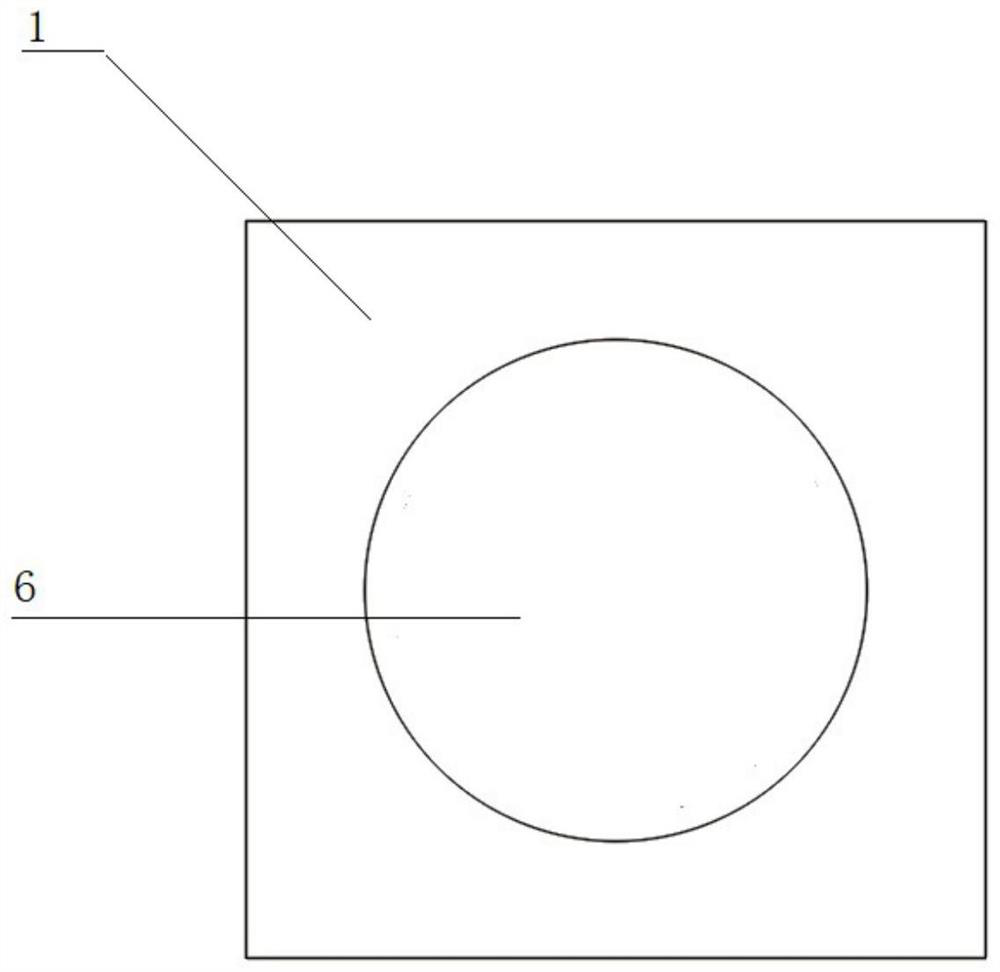

[0026] like Figure 1-3 As shown, it is a schematic diagram of the structure of the application. In this embodiment, the body 1 is a metal block, a cylindrical metal block protrusion 2 is provided in the center of the top of the body 1, and a cylindrical first metal block protrusion 2 is provided in the center of the cylindrical metal block protrusion 2. The cavity 3 is provided with a cylindrical second cavity 4 at the bottom of the body 1. The first cavity 3, the second cavity 4 and the cylindrical metal block protrusion 2 are concentric, and the first cavity 3 and the second cavity are concentric. A thin film 5 with a thickness of 0.6 mm is arranged in the space 4 , and resistance strain gauges 7 are evenly distributed on the annular surface of the top of the second cavity 4 beyond the first cavity 3 .

[0027] In this embodiment, the diameter of the second cavity 4 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com