Underwater construction waste metal screening device

A technology of underwater construction and metal sieve, which is applied in the fields of filtration, solid separation, magnetic separation, etc., can solve the problems of low recovery efficiency, water environment pollution, complex process, etc., and achieve high efficiency, high degree of automation, and reduced manpower manipulation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

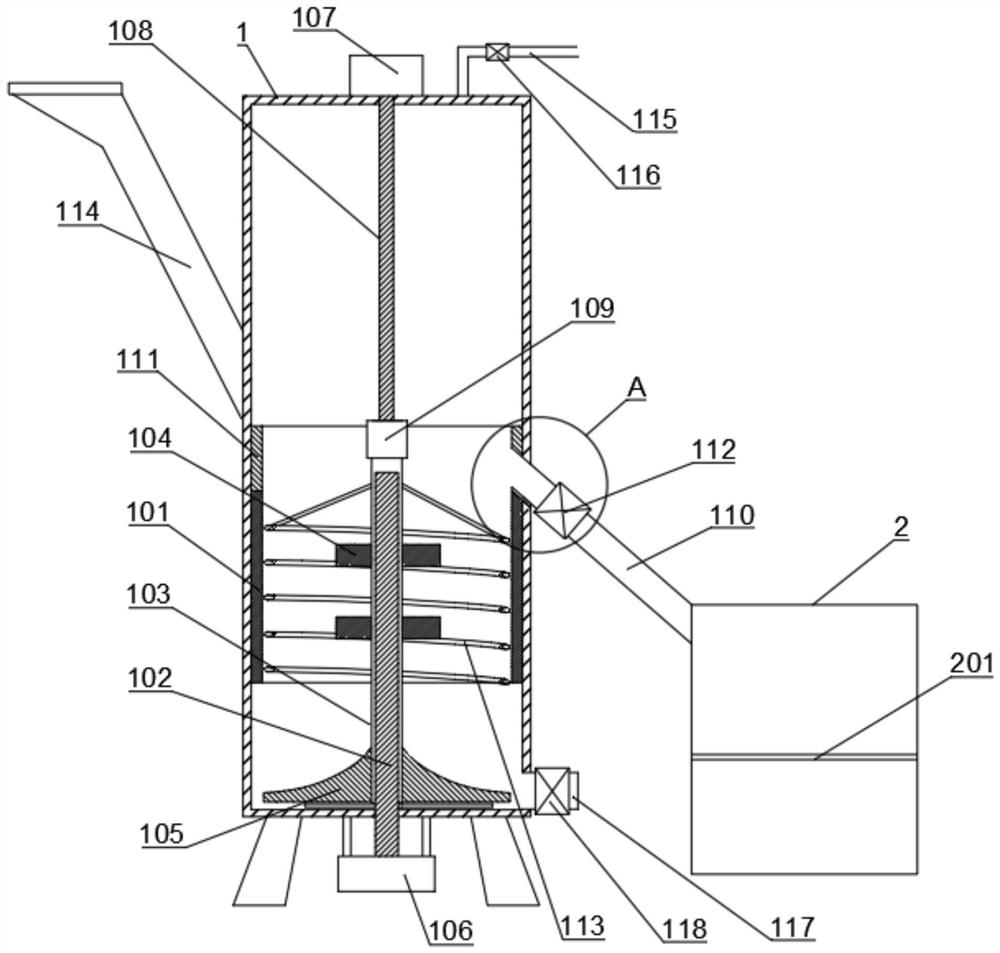

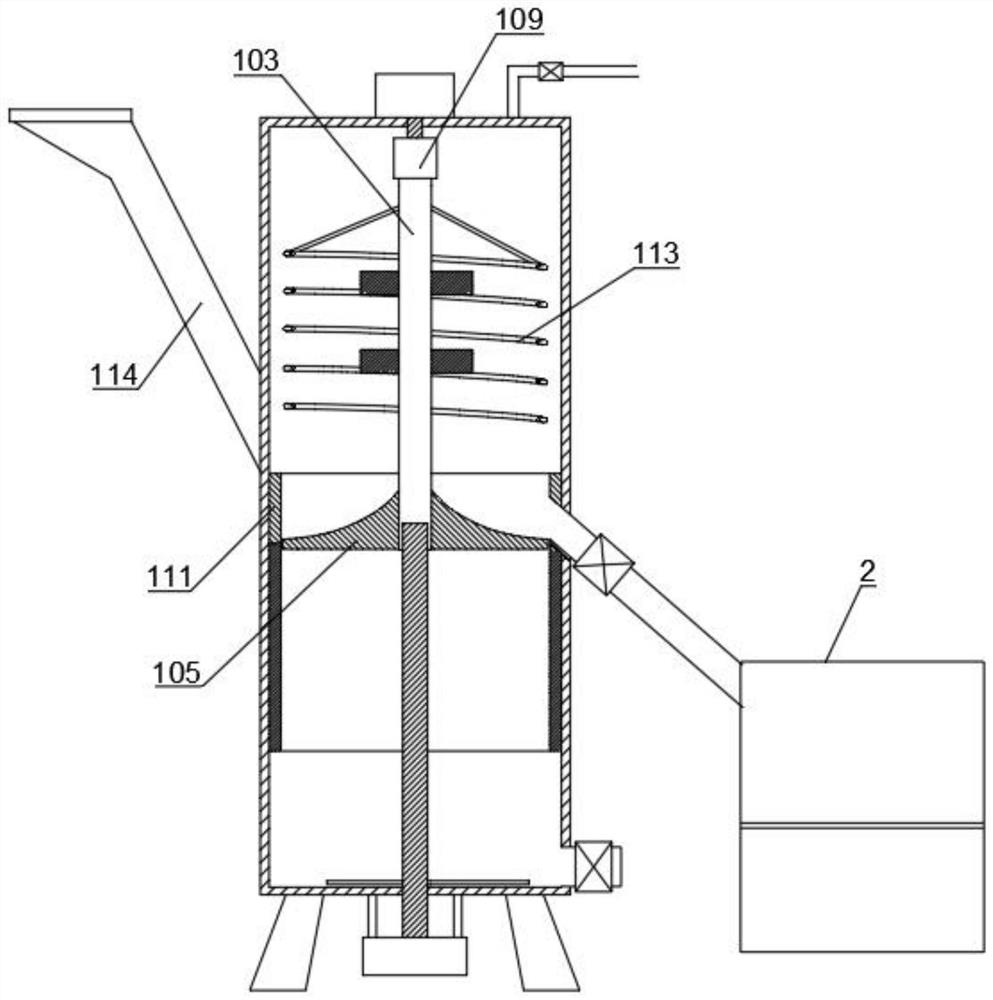

[0033] This embodiment provides a metal screening device for underwater construction waste, such as Figure 1 to Figure 4 shown, including metal screening barrel 1;

[0034] The inner side of the metal screening barrel 1 is provided with a cylindrical magnet 101, the cylindrical magnet 101 is hollow inside, and is coaxially arranged with the metal screening barrel 1;

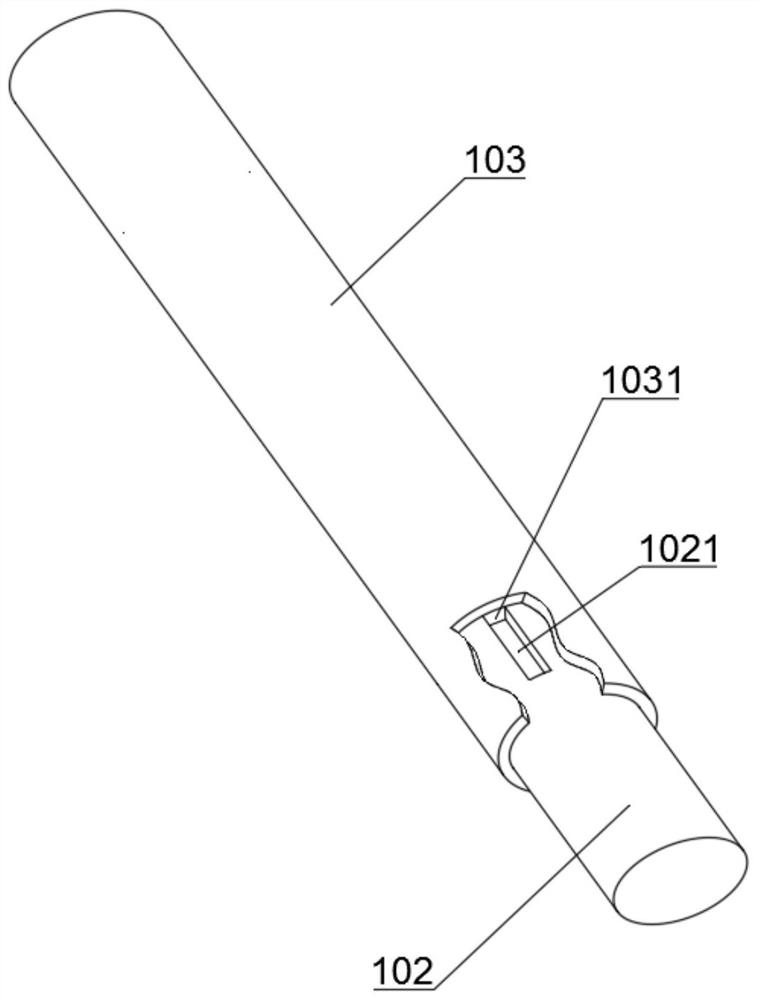

[0035] There is also a main shaft 102 along the axis of the metal screening barrel 1, the main shaft 102 can rotate around its own axis, and a hollow shaft 103 is sleeved on the outer side of the main shaft 102, and the main shaft 102 is used to drive the hollow shaft. 103 rotates, the hollow shaft 103 can move along the length direction of the main shaft 102, and a plurality of blades 104 are arranged on the outer side of the hollow shaft 103;

[0036] The bottom of the hollow shaft 103 is fixedly sleeved with an annular scraper device 105. During the upward movement of the annular scraper device 105 from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com