Automatic feeding device of pressure-sensitive adhesive tape production line

A pressure-sensitive adhesive tape, automatic feeding technology, applied in thin material handling, transportation and packaging, transportation of filamentous materials, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

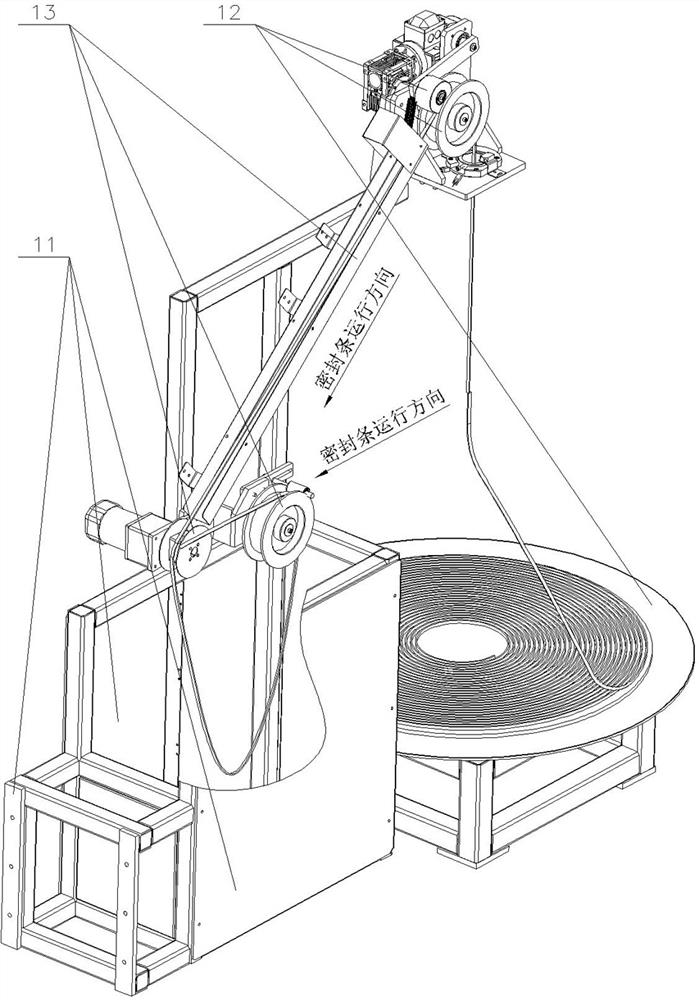

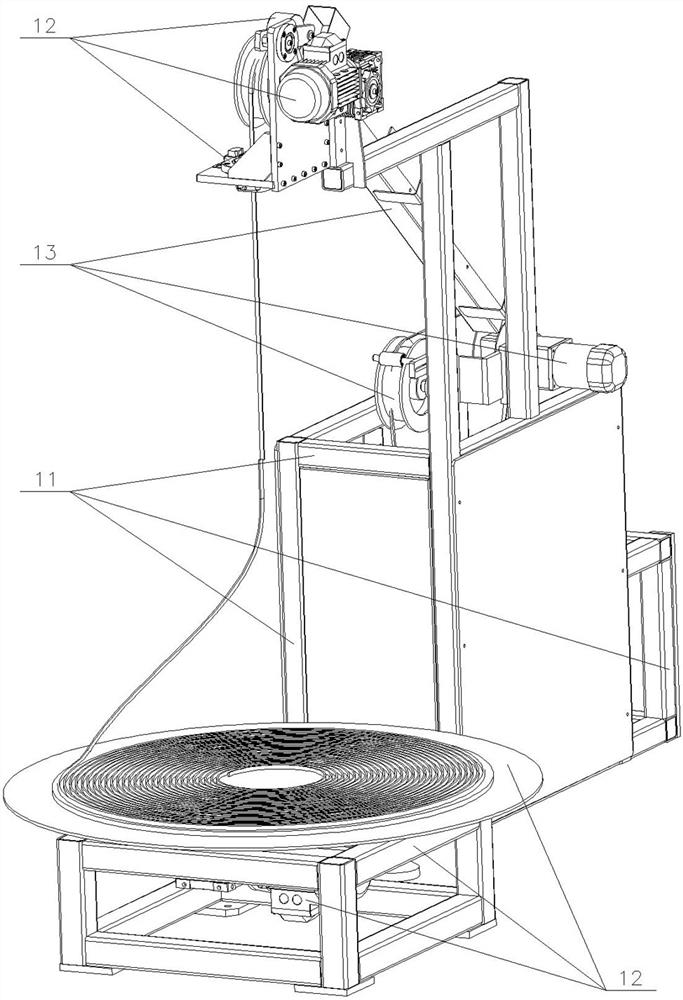

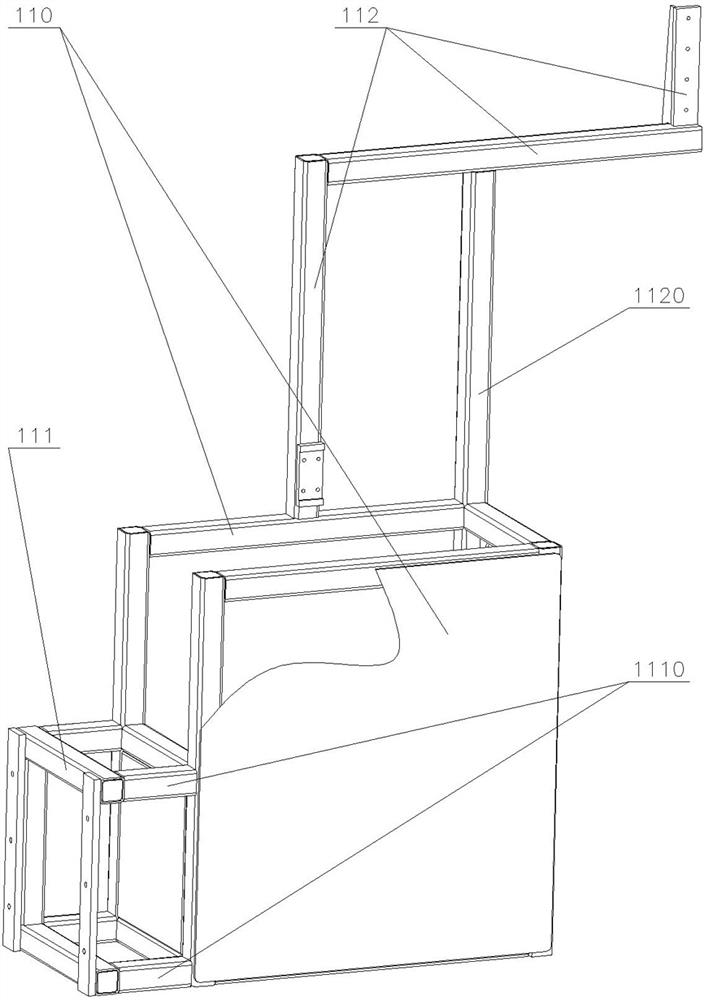

[0024] 11. Feeding frame 110, protective case 1110, outriggers 111, connecting frame 112, support frame 1120, supporting rod 12, torsion detection feeding device 120, traction detection device 1200, feeding traction device 12000, feeding mounting plate 12001, feeding traction drive 12002, feeding wheel 12003, feeding rocker arm 12004, beading wheel 12005, feeding tension spring 1201, detecting and guiding device 12010, detecting mounting plate 12011, feeding base 12012, feeding die 12013, Material break sensor 12014, torsion sensor 121, reverse torsion device 1210, torsion frame 1211, torsion mounting plate 1212, torsion sleeve 1213, reverse torsion drive 1214, torsion driving wheel 1215, torsion driven wheel 1216, torsion disc 13, pendulum Shake blanking mechanism 130, shake drive mechanism 1300, shake mounting plate 1301, shake drive 1302, shake wheel 1303, shake support legs 1304, bead roller 131, guide groove 1310, guide groove body 1311, guide Bar sleeve 1312, guide bar l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com