Control method for reducing iron loss by reasonably matching scrap steel in 120t converter

A control method and converter technology, applied to furnaces, blast furnaces, furnace types, etc., can solve the problems of reducing the steel output of 120t converters, increasing the production cost of converter smelting, and being unable to use them reasonably, so as to improve the utilization efficiency of converters and realize Low-cost smelting and the effect of maximizing the production capacity of a single furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solutions will be clearly and completely described below with reference to the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without making creative efforts shall fall within the protection scope of the present invention.

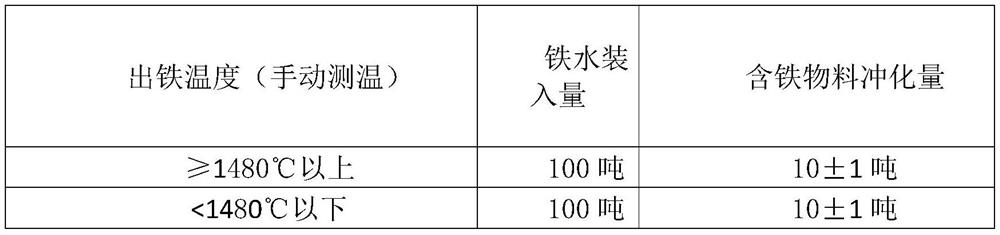

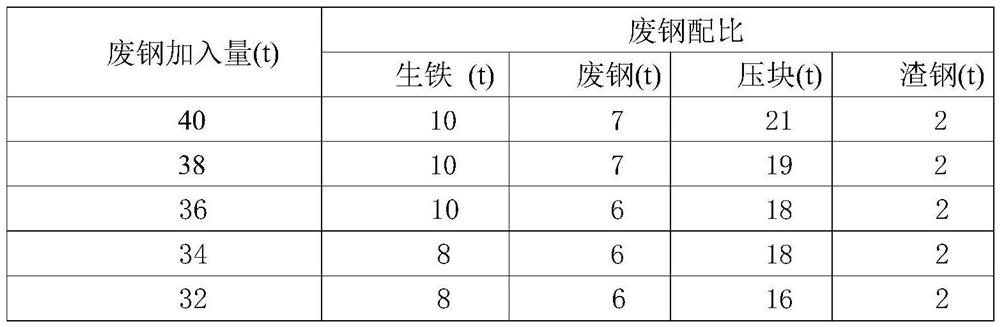

[0040] The present invention provides a kind of technical scheme: a kind of control method that 120t converter reasonably matches scrap steel to reduce iron consumption, comprises the following steps:

[0041] S1: Heating preparation stage:

[0042] S11: After the iron-containing material is added to the molten iron tank, add a baking device on the running track of the molten iron tank;

[0043] S12: Connect the power supply of the baking mechanism to the external power supply, start the baking me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com