Turnover equipment for automobile carpet production

A technology for automobile carpets and equipment, applied in the field of turning equipment, can solve the problems of time-consuming and laborious, easy to damage carpets and easy to turn over by mistake or leakage, and achieve the effects of improving stability, improving production and processing efficiency, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

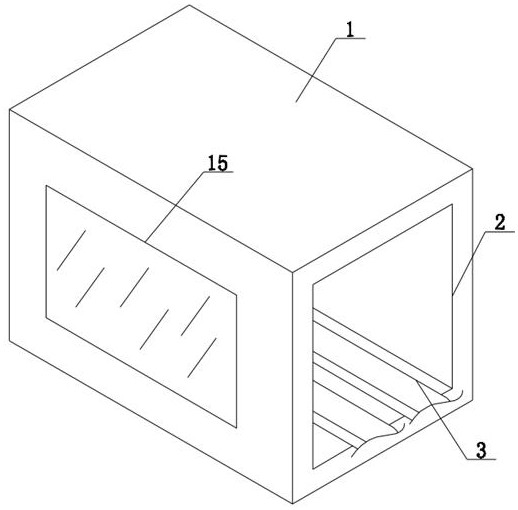

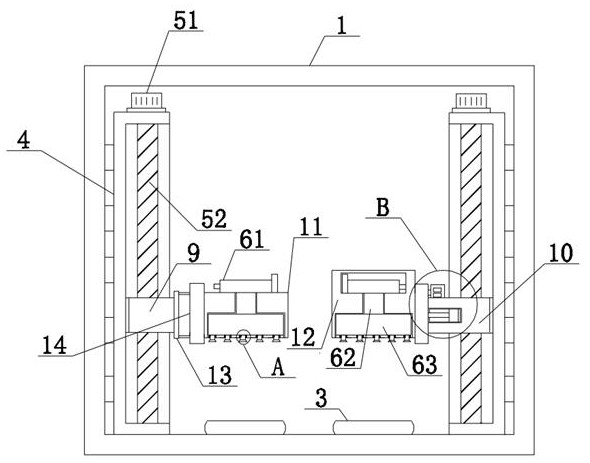

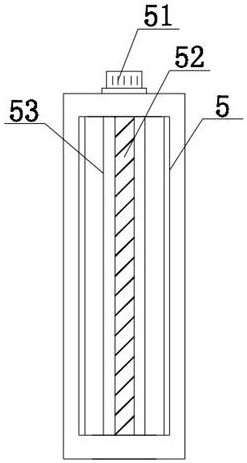

[0040] see Figure 1-9 , a turning device for automobile carpet production, comprising a processing box 1, a conveying hole 2 is opened inside the processing box 1, a conveyor belt body 3 is fixedly connected to the bottom end of the conveying hole 2, and the conveyor belt body 3 is provided with two groups, one One group is the conveyor belt body 3 for feeding the carpet, and the other group is the conveyor belt body 3 for feeding the carpet. The inside of the conveying hole 2 is fixedly connected with a fixed seat 4. The fixed seat 4 is symmetrically provided with two groups, and one side of the fixed seat 4 is provided with lifting Assembly 5, a first sliding seat 9 is slidably connected to the inside of one set of fixed bases 4 through the lifting assembly 5, and the second sliding seat 10 is slidably connected to the inside of the other set of fixed bases 4 through the lifting assembly 5. A turning cylinder 13 is installed on one side, a positioning seat 14 is arranged on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com