Section steel splicing device

A splicing device and section steel technology, which is applied in construction, excavation, and infrastructure engineering, can solve the problems of incorrect assembly, impact on construction period, and low processing efficiency, so as to facilitate design and construction, improve overall stability, and improve construction efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

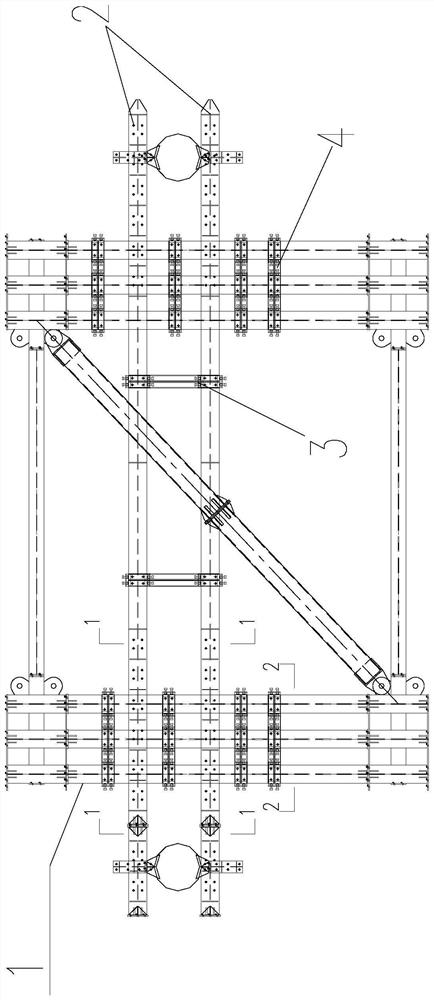

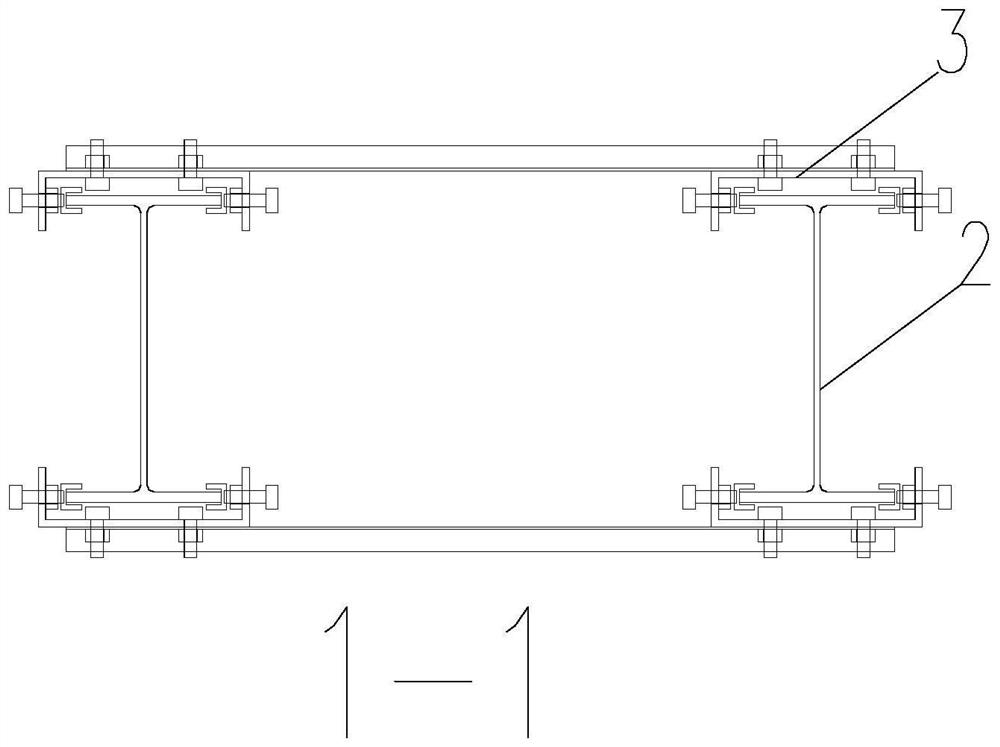

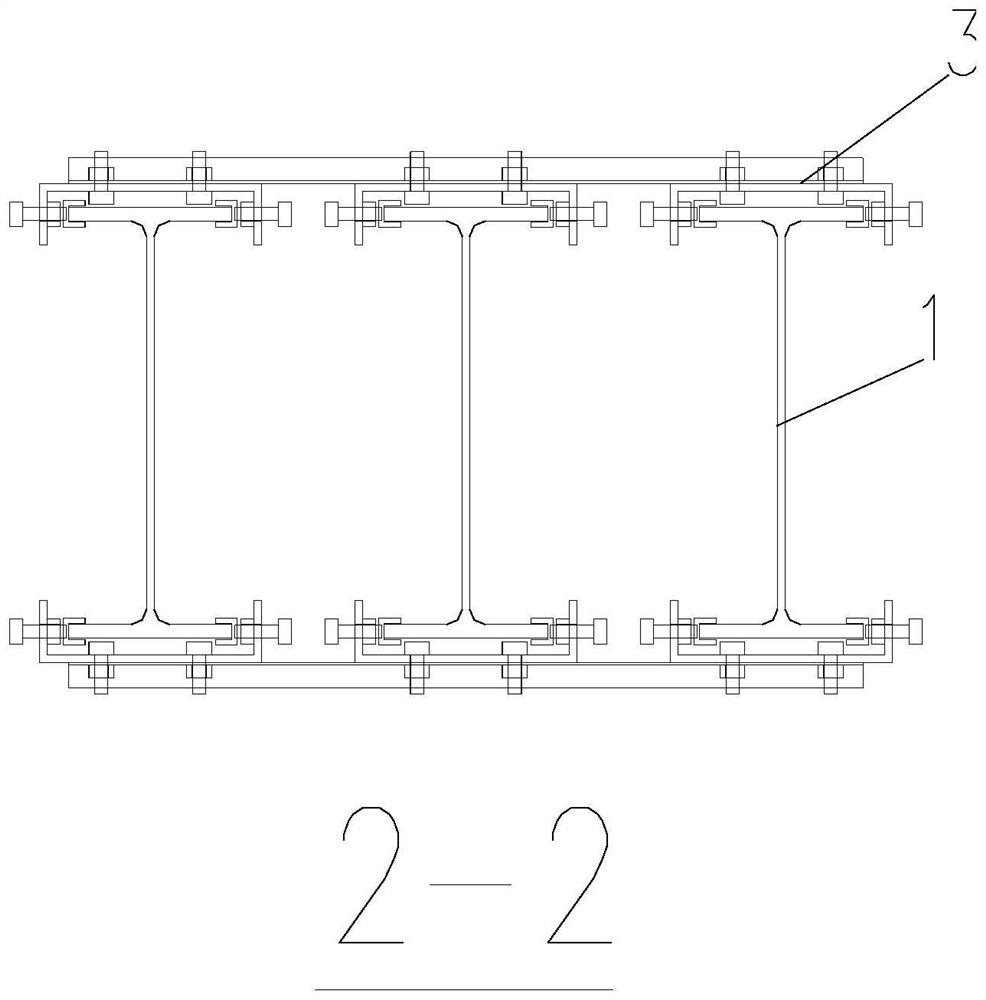

[0030] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

[0031] see Figure 1-Figure 8 , a profiled steel splicing device, comprising a connecting piece 301 and a high-strength fixture 302; the high-strength fixture 302 comprises a channel-shaped piece 302a, the channel-shaped piece 302a includes a channel-shaped steel 302a2 and a nut 302a1, and the channel-shaped steel 302a2 has a The connecting piece 301 is attached to a fastened plane, and two sides of the plane extend vertically in the same direction with a bent portion. At least a pair of nuts 302a1 are screwed and installed on the bent portion and face each other. The front end of the nut 302a1 is fixedly connected with the U-shaped buckle 302c, and a pair of the U-shaped buckles 302c forms a tendency to snap and clamp the edge portion of the shaped steel part.

[0032] In this example, see figure 1 , the profiled steel component is the profile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com