Punched outer ring bearing needle installation and flexibility detection machine

A stamping outer ring, flexible technology, applied in the field of automatic parts assembly and testing, can solve the problems of low fitting and testing efficiency, poor stability of finished products, many uncertain factors, etc., to achieve high testing accuracy and reliability, and a degree of automation. High and versatile effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The preferred embodiments of the present invention are described in detail below with reference to the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, and the protection scope of the present invention can be more clearly defined.

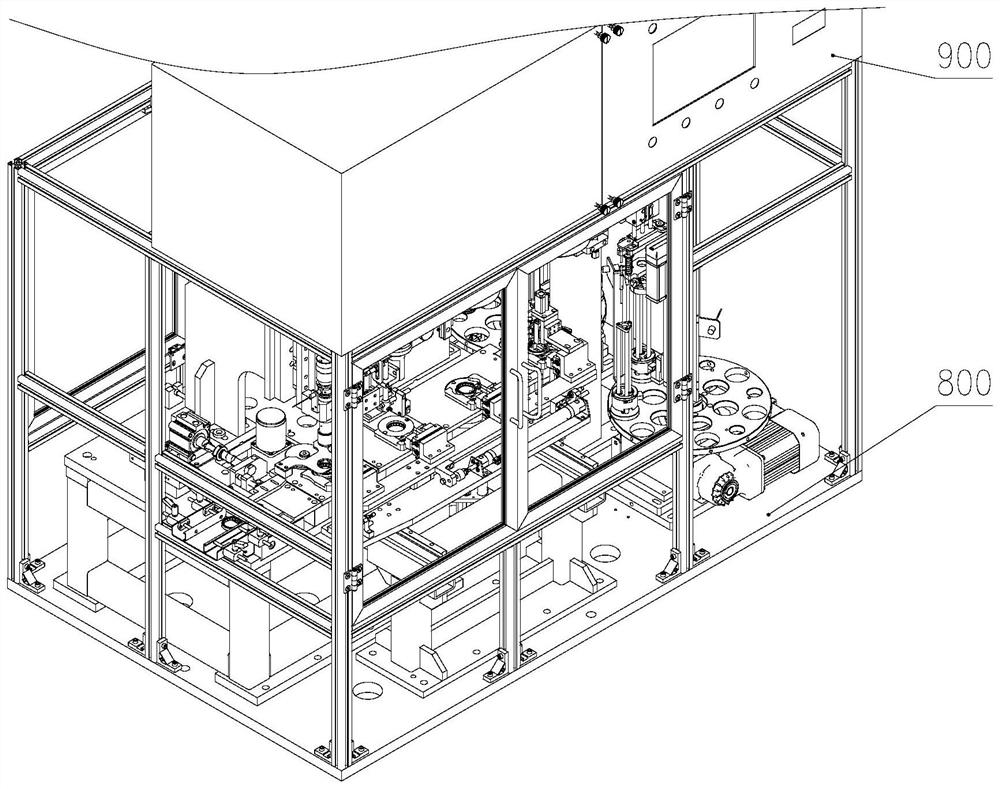

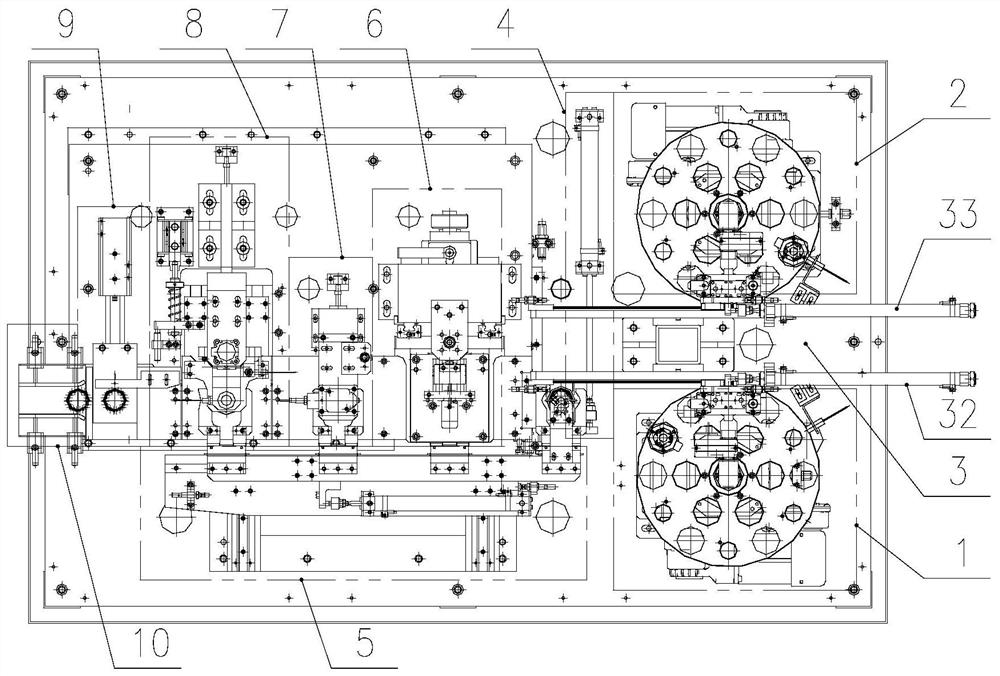

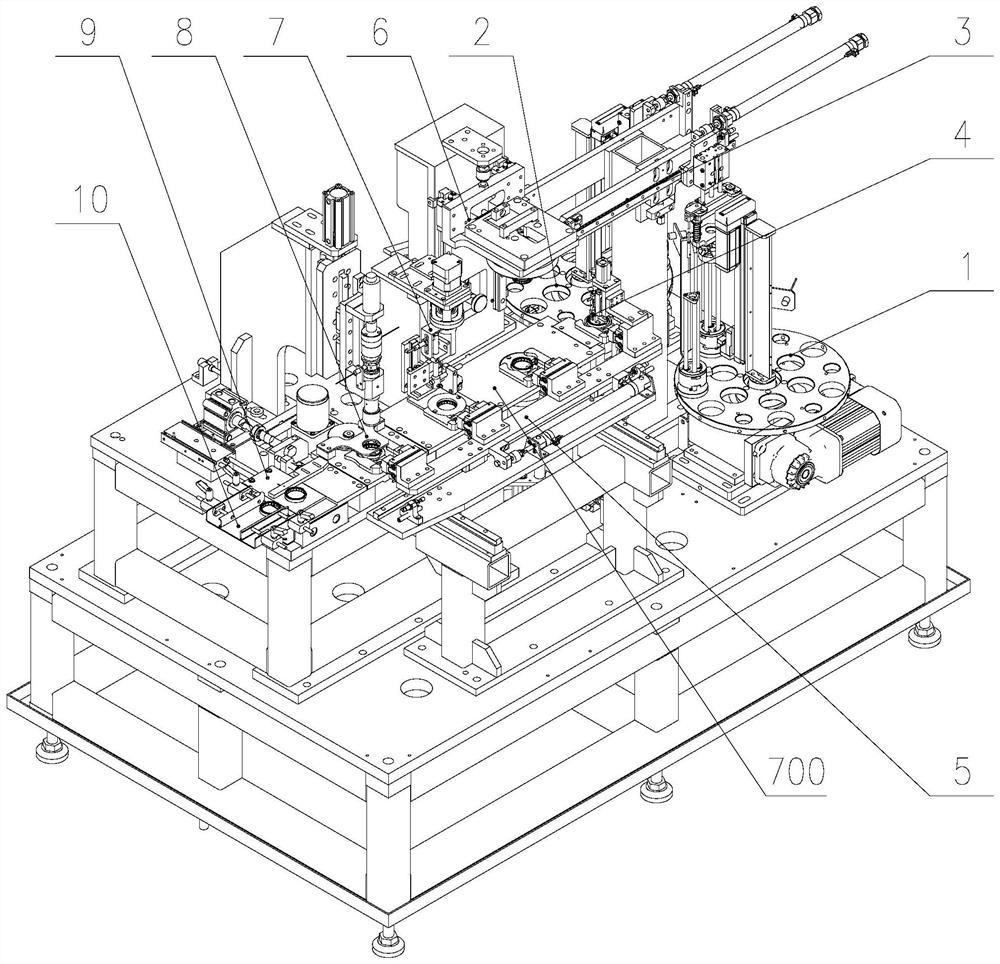

[0053] like Figure 1-3 The illustrated machine for needle mounting and flexibility testing of a stamped outer ring bearing includes an electric box control device 900, a bench 800, a working platform 700 set in the bench 800, a stamped outer ring silo 1, and a cage Silo 2, manipulator assembly 3, cage stamping outer ring fitting part 4, conveying manipulator 5, needle loading part 6, needle missing detection part 7, flexibility detection part 8, NG discharge part 9 and discharge part 10, The needle loading part 6 , the needle missing detection part 7 and the flexibility detection part 8 are sequentially arranged on one side of the working platform 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com