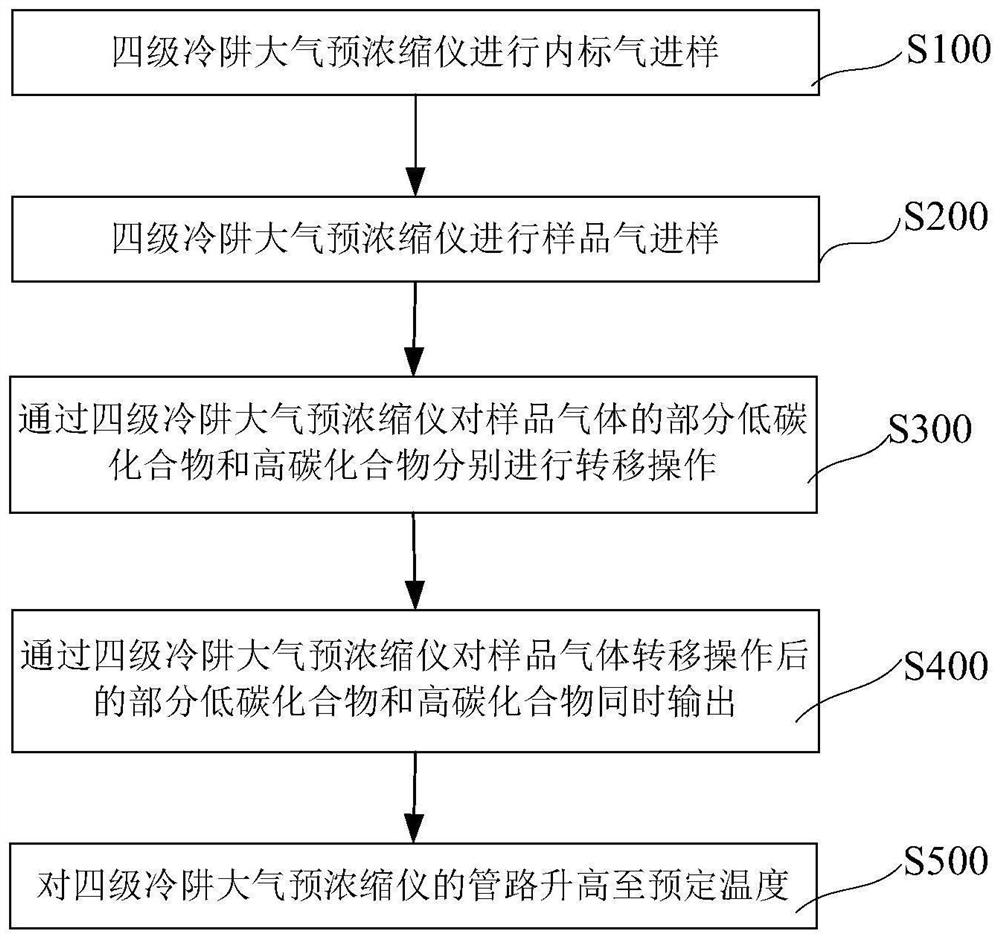

Four-stage cold trap atmosphere preconcentrator and concentration method thereof

An atmospheric pre-concentrator technology, applied in the field of chemical analysis, can solve the problems affecting the accuracy of samples, poor water removal effect of the three-stage cold trap atmospheric pre-concentrator, and short peaks of high-carbon compounds, and achieves improved separation and removal. Water effect, prolong life, improve accuracy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

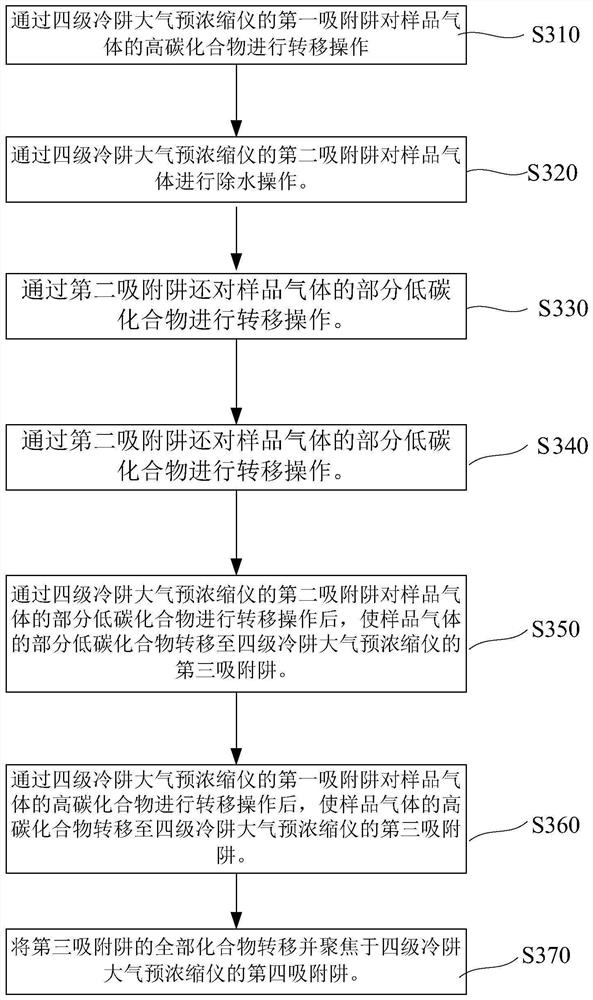

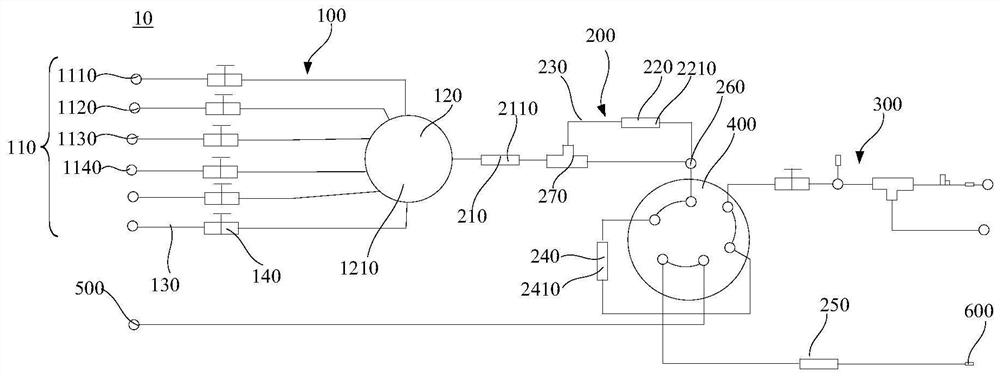

[0067] The first step is to inject the sample to be tested: control the temperature of the first adsorption trap to the set temperature (20°C), control the temperature of the second adsorption trap to the set temperature (-20°C), and control the temperature of the third adsorption trap When the temperature reaches the set temperature (-100°C), the temperature of the fourth adsorption trap is controlled to the set temperature (-20°C). Open the internal standard gas port and input the sample to be tested. At this time, the entire passage is in a state of being filled with the sample to be tested.

[0068] The second step of sample gas injection: close the sample port to be tested, open the sample gas inlet, and let the sample gas enter the pipeline of the fourth-stage cold trap atmospheric preconcentrator. At this time, the non-absorbent medium set in the first adsorption trap is not Weak adsorbent that absorbs water, the first adsorption trap corresponds to adsorbing high-carbon...

Embodiment 2

[0073] The first step is to inject the sample to be tested: control the temperature of the first adsorption trap to the set temperature (80°C), control the temperature of the second adsorption trap to the set temperature (-5°C), and control the temperature of the third adsorption trap When the temperature reaches the set temperature (-10°C), the temperature of the fourth adsorption trap is controlled to the set temperature (0°C). Open the internal standard gas port and input the sample to be tested. At this time, the entire passage is in the internal standard state.

[0074] The second step of sample gas injection: close the sample port to be tested, open the sample gas inlet, and let the sample gas enter the pipeline of the fourth-stage cold trap atmospheric preconcentrator. At this time, the non-absorbent medium set in the first adsorption trap is not Strong adsorbent that absorbs water, the first adsorption trap corresponds to the adsorption of high-carbon compounds, and may...

Embodiment 3

[0078] The first step is to inject the sample to be tested: control the temperature of the first adsorption trap 0 to the set temperature (50°C), control the temperature of the second adsorption trap 4 to the set temperature (-10°C), and control the temperature of the third adsorption trap to the set temperature (-10°C). The temperature is controlled to the set temperature (-40°C), the temperature of the fourth adsorption trap is controlled to the set temperature (-10°C), the internal standard gas port is opened, and the sample to be tested is input. At this time, the entire passage is in the internal standard state.

[0079] The second step of sample gas injection: close the sample port to be tested, open the sample gas inlet, and let the sample gas enter the pipeline of the fourth-stage cold trap atmospheric preconcentrator. At this time, the non-absorbent medium set in the first adsorption trap is not Strong adsorbent that absorbs water, the first adsorption trap corresponds...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap