Rubber production problem rapid positioning method based on rubber blooming defect

A positioning method and rubber technology, applied in image analysis, image enhancement, instruments, etc., to achieve precise positioning and improve inspection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

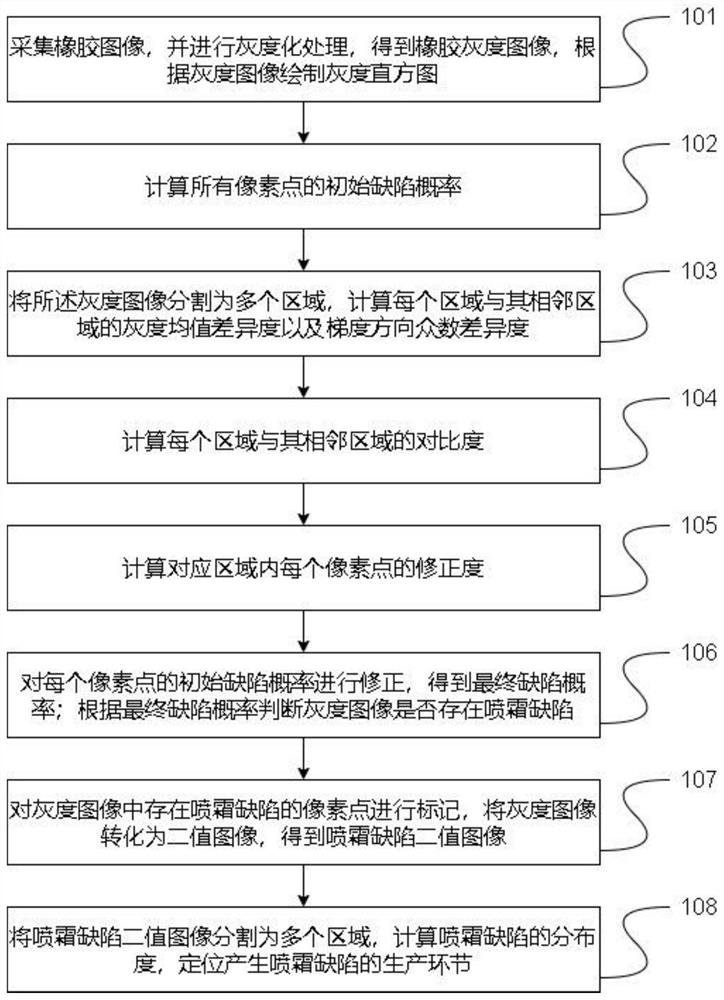

[0056] like figure 1 As shown, a schematic flowchart of a method for quickly locating rubber production problems based on rubber bloom defects according to an embodiment of the present invention is provided, including:

[0057] 101. Collect a rubber image and perform grayscale processing to obtain a rubber grayscale image, and draw a grayscale histogram according to the grayscale image.

[0058] The specific scenario for this embodiment is: in the rubber production process, due to production process problems, a frost spray defect occurs on the rubber surface. It is necessary to detect and analyze the blooming defects, and then locate the production link that produces the blooming defects.

[0059] In this embodiment, the frost spray defect needs to be detected according to the characteristics of the rubber image, so the rubber image needs to be collected first, and the information of the connected domain of the rubber in the image needs to be identified. Position the camera ...

Embodiment 2

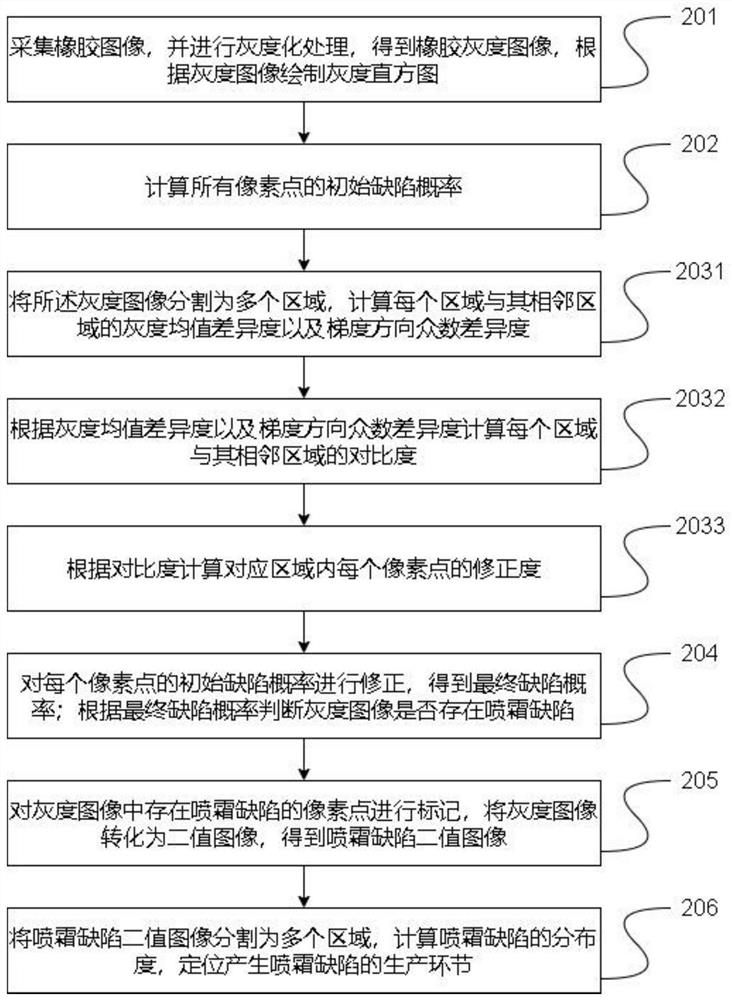

[0082] like figure 2 As shown, a schematic flowchart of a method for quickly locating rubber production problems based on rubber bloom defects according to another embodiment of the present invention is provided, including:

[0083] 201. Collect a rubber image and perform grayscale processing to obtain a rubber grayscale image, and draw a grayscale histogram according to the grayscale image.

[0084] Position the camera right above the rubber and take an image of the rubber with the background and the rubber in it.

[0085] The present invention adopts the way of DNN semantic segmentation to identify the target in the segmented image.

[0086] The relevant content of the DNN network is as follows:

[0087] The dataset used is the rubber image dataset collected from the top down.

[0088] The pixels that need to be segmented are divided into two categories, that is, the corresponding label labeling process of the training set is: single-channel semantic label, the label of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com