Composite hippophae rhamnoides fruit juice and preparation process thereof

A technology of sea buckthorn juice and preparation technology, applied in the direction of food science, can solve problems such as unfavorable health, and achieve the effect of ensuring the preservation time and improving the taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

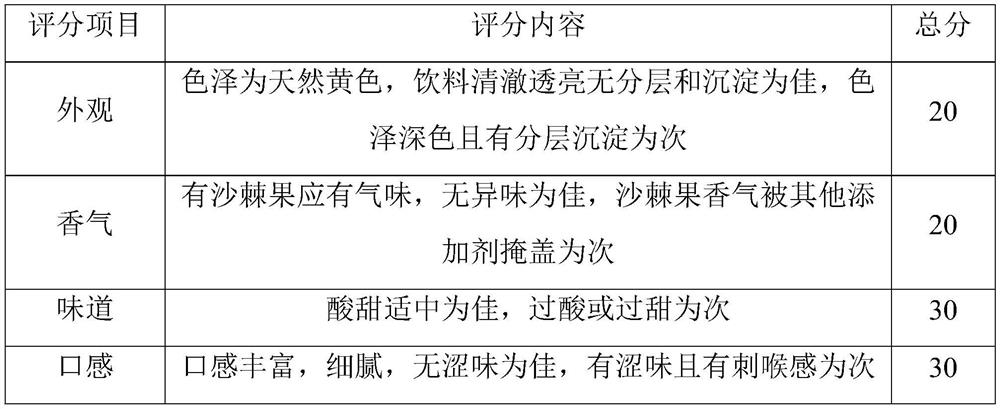

Examples

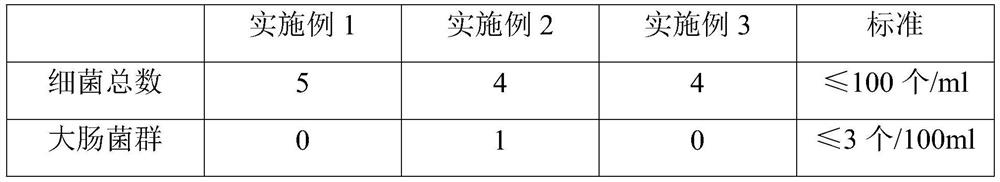

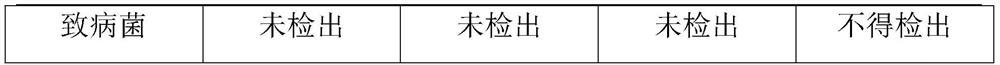

Embodiment 1

[0026] First, thaw the refrigerated sea buckthorn fruit water bath in a 5-meter-long water tank with pure water at about 40°C, then boil and wash it in a 4-meter-long water tank with 25°C pure water, and finally spray and drain with room temperature pure water. The sea buckthorn fruit is firstly crushed and beaten to obtain pulp residue, and then the pulp residue is subjected to secondary beating. Phase disc separator, four-stage "liquid-liquid-solid" three-phase separation to obtain sea buckthorn puree, add 150 parts of sea buckthorn puree and 100 parts of decolorized and deacidified pear juice into the raw material tank, stir and homogenize to obtain Juice puree, the puree juice is subjected to high temperature instantaneous sterilization, the sterilization temperature is 105 ℃, and the time is controlled within 15 seconds. After sterilization, ice water is used for instant cooling, and the pure juice is cooled to below 25 ℃. The composite juice after sterilization and coolin...

Embodiment 2

[0028] First, thaw the refrigerated sea buckthorn fruit water bath in a 5-meter-long water tank with pure water at about 40°C, then boil and wash it in a 4-meter-long water tank with 25°C pure water, and finally spray and drain with room temperature pure water. The sea buckthorn fruit is firstly crushed and beaten to obtain pulp residue, and then the pulp residue is subjected to secondary beating. Phase disc separator, four-stage "liquid-liquid-solid" three-phase separation to obtain sea buckthorn puree, add 120 parts of sea buckthorn puree and 75 parts of decolorized and deacidified pear juice into the raw material tank, stir and homogenize to obtain Juice puree, the puree juice is subjected to high temperature instantaneous sterilization, the sterilization temperature is 104°C, and the time is controlled within 15 seconds. After sterilization, ice water is used for instant cooling, and the puree juice is cooled to below 25°C. The composite juice after sterilization and coolin...

Embodiment 3

[0030] First, thaw the refrigerated sea buckthorn fruit water bath in a 5-meter-long water tank with pure water at about 40°C, then boil and wash it in a 4-meter-long water tank with 25°C pure water, and finally spray and drain with room temperature pure water. The sea buckthorn fruit is firstly crushed and beaten to obtain pulp residue, and then the pulp residue is subjected to secondary beating. Phase disc separator, four-stage "liquid-liquid-solid" three-phase separation to obtain sea buckthorn puree, add 100 parts of sea buckthorn puree and 50 parts of decolorized and deacidified pear juice into the raw material tank, stir and homogenize to obtain Juice puree, high temperature instant sterilization of puree juice, sterilization temperature 103 ℃, time controlled within 15 seconds, instant cooling with ice water after sterilization, cooling the pure juice to below 25 ℃, the composite juice after sterilization and cooling, Filled in aseptic brick packs through a low temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com