Telescopic transfer bracket device and beam transporting vehicle

A technology of bracket device and bracket assembly, which is applied in the direction of object transportation vehicles, transportation and packaging, and vehicles used for freight transportation, etc., which can solve problems such as delay in construction period, time-consuming, and inapplicability, and achieve improved support stability and improved Transshipment efficiency, effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

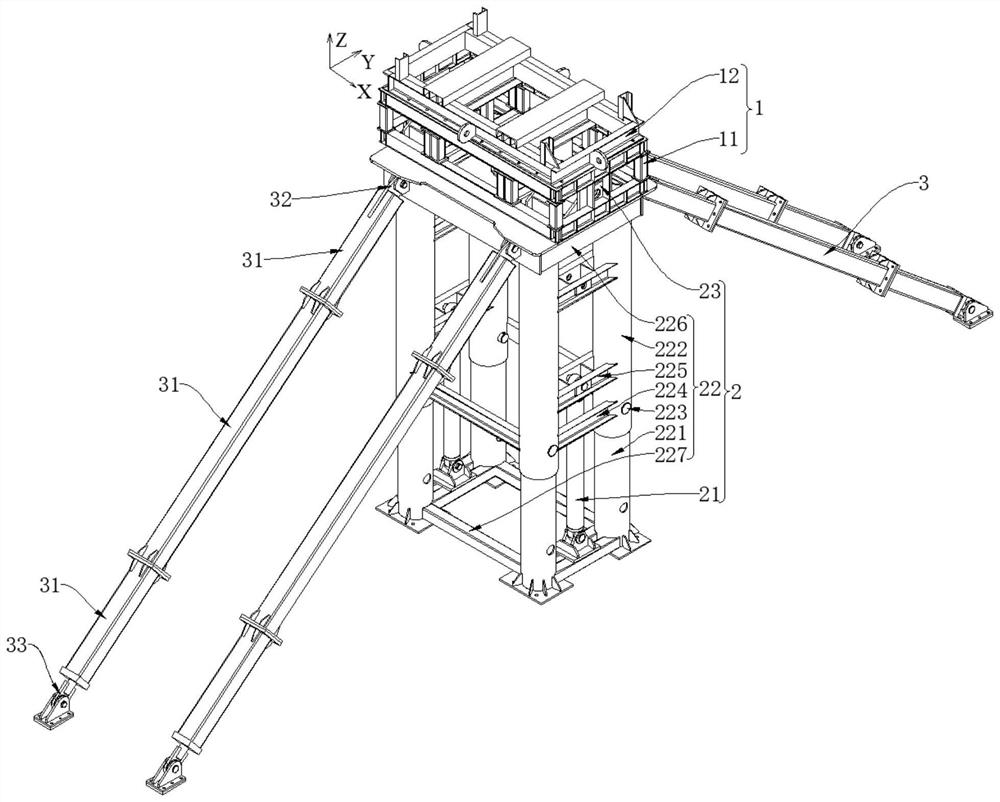

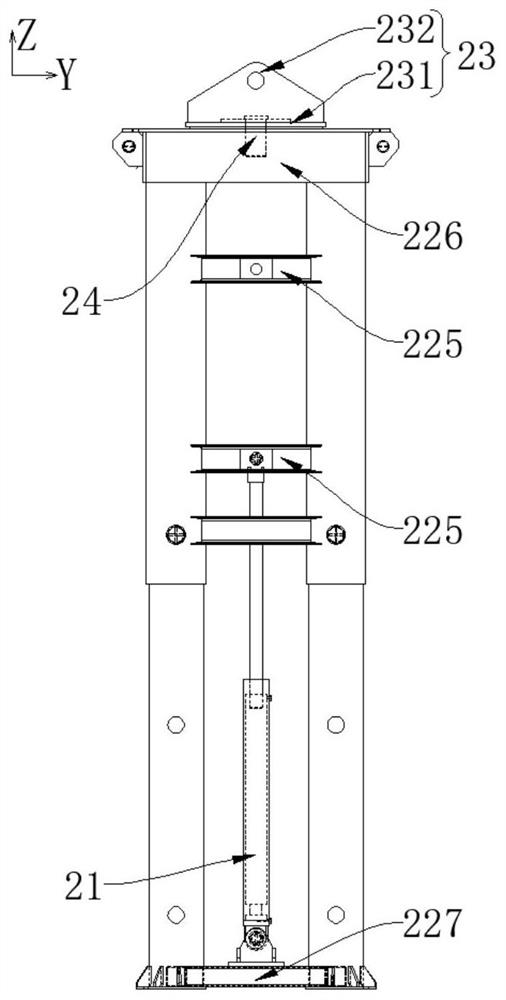

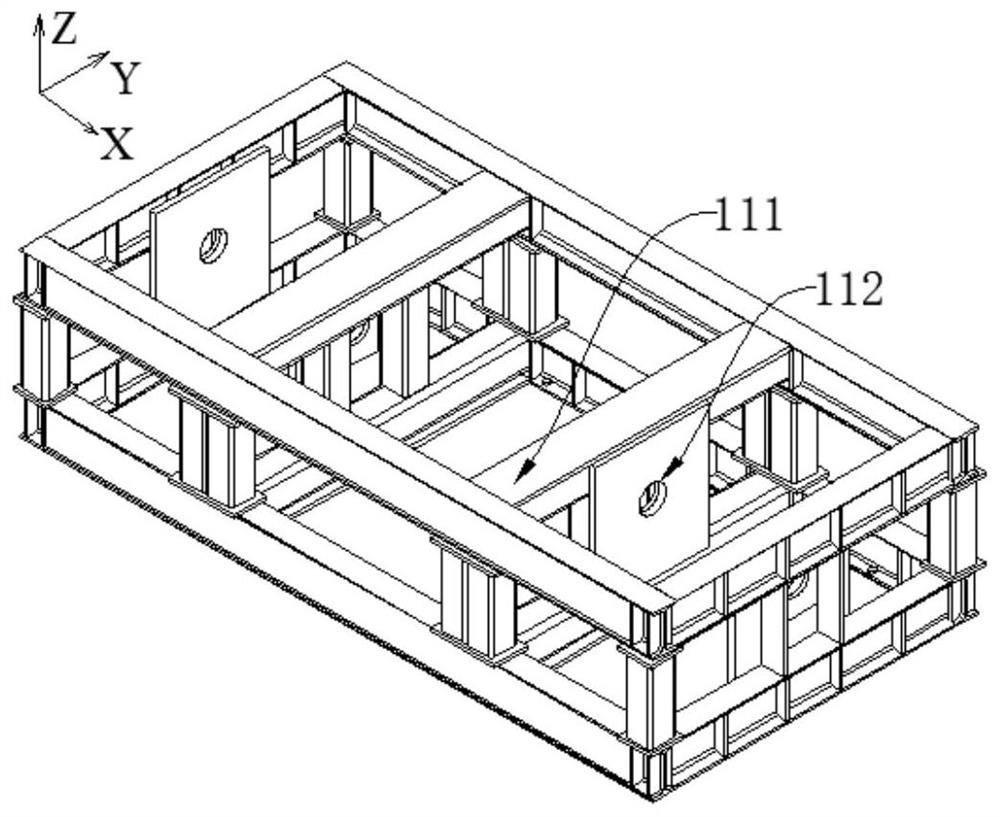

[0025] In order to make the above objects, features and advantages of the present invention more clearly understood, the specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0026] It should be noted that in the coordinate system XYZ provided in this article, the positive direction of the X axis represents the right, the reverse of the X axis represents the left, the positive direction of the Y axis represents the rear, the reverse of the Y axis represents the front, and the reverse of the Z axis represents the front. The positive direction represents up, and the reverse of the Z axis represents down. At the same time, it should be noted that the terms "first", "second" and the like in the description and claims of the present invention and the above-mentioned drawings are used to distinguish similar objects, and are not necessarily used to describe a specific order or sequence. order. It is to be under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com