Hydraulic damper

A technology of hydraulic dampers and hydraulic cylinders, which is applied to liquid shock absorbers, shock absorbers, shock absorbers, etc., and can solve problems such as inability to adjust the damping coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

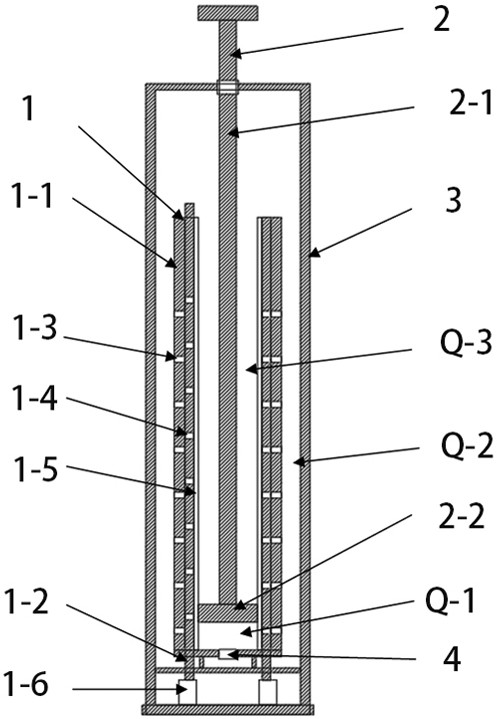

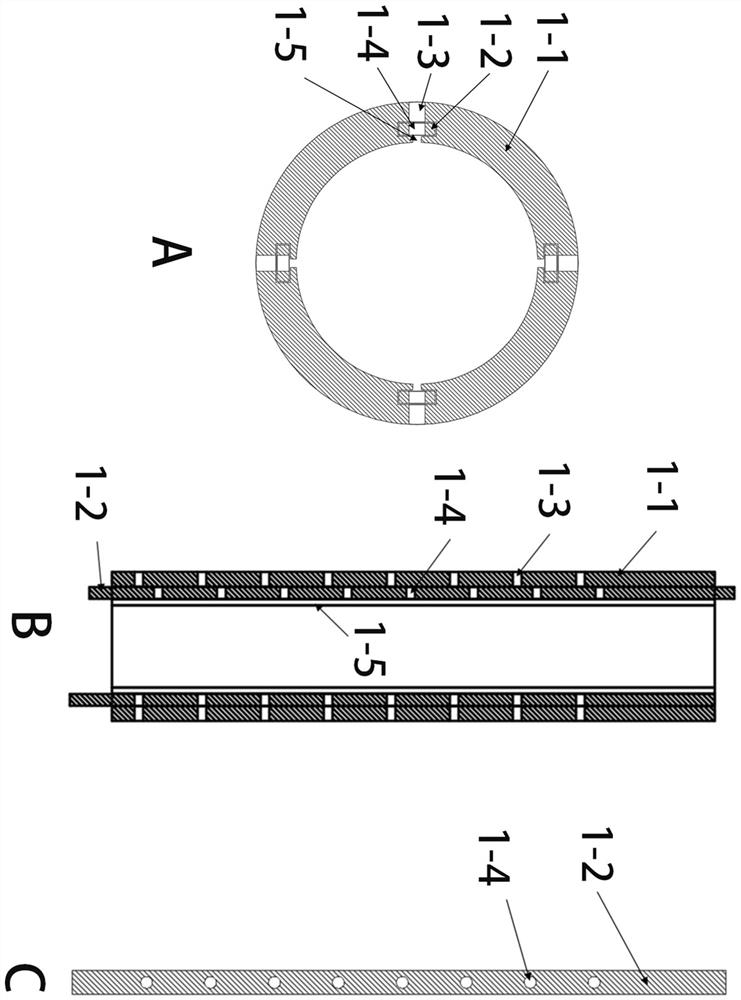

[0015] Referring to the accompanying drawings, a hydraulic damper includes: an outer casing 3, a hydraulic cylinder 1, a piston 2, a one-way valve 4; a switch flap 1-2; a switch flap driving device 1-6; the hydraulic cylinder 1 is arranged in the outer casing 3; the hydraulic cylinder is provided with a piston 2-2 that moves along the axial direction of the hydraulic cylinder; an overflow chamber Q-2 is formed between the outer casing 3 and the inner hydraulic cylinder 1; The hydraulic working pressure chamber Q-1 with variable volume is defined by the inner end of the piston 2-2 and the hydraulic cylinder; the hydraulic cylinder has a hydraulic balance chamber Q-3 with variable volume, the hydraulic pressure The balance chamber Q-3 is defined in the annular space between the outer end of the piston 2-2 and the hydraulic cylinder, the pressure chamber Q-1 and the balance chamber Q-3 are separated by the piston 2-2 in the hydraulic cylinder, and the balance chamber Q -3 is dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com