High-low temperature current-carrying fatigue test system for air-conditioning duct of airplane

An air-conditioning air duct and fatigue testing technology, which is applied in the field of simulation test, can solve problems such as difficulty in air duct maintenance and repair, pipeline leakage, thermal insulation and sealing that affect the temperature adjustment efficiency of air-conditioning units, and achieve the effect of saving maintenance and upgrading costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

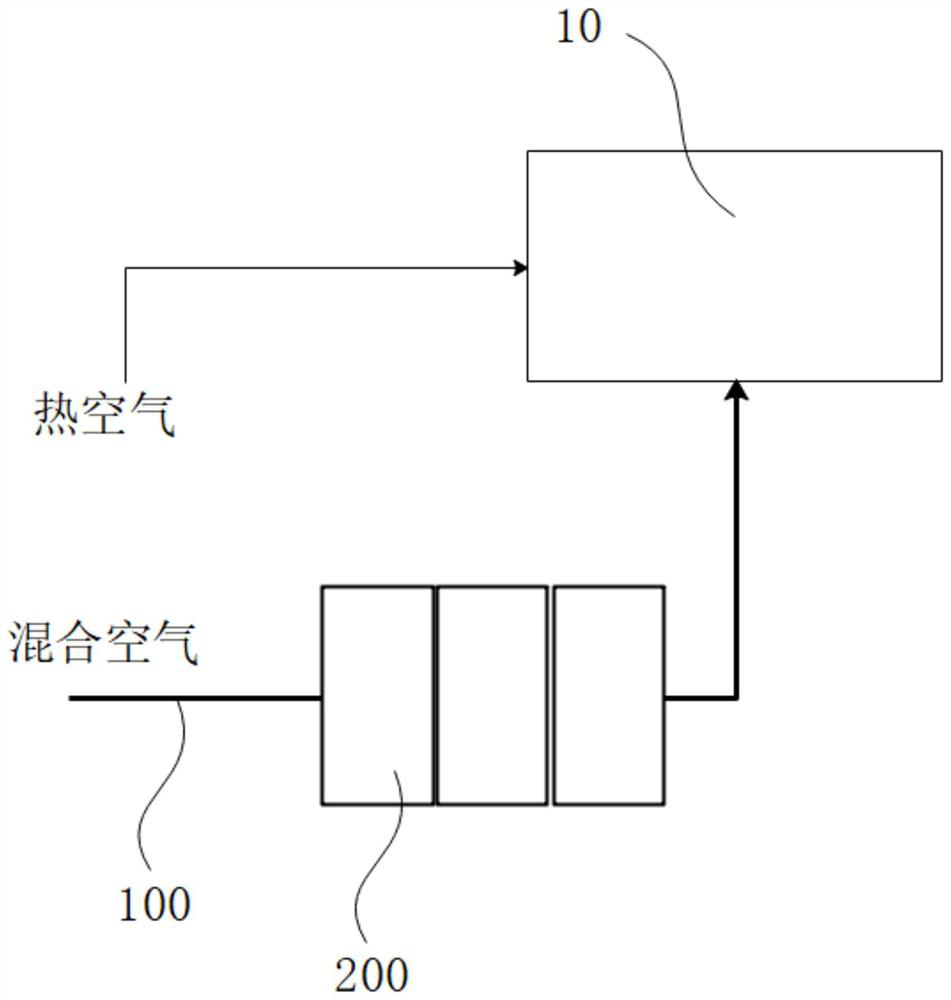

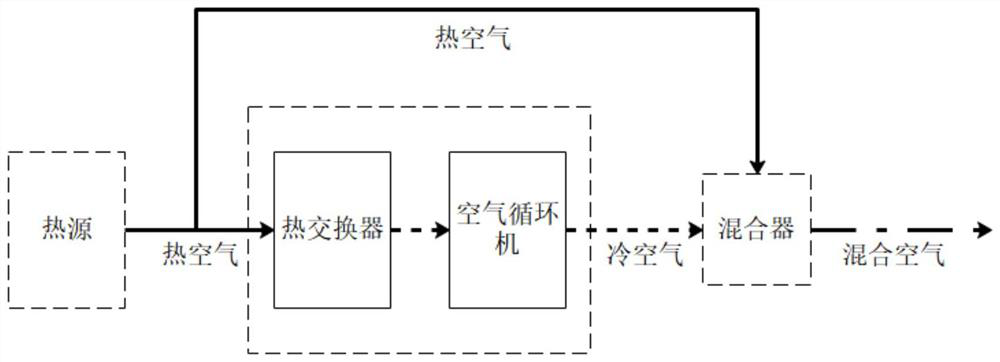

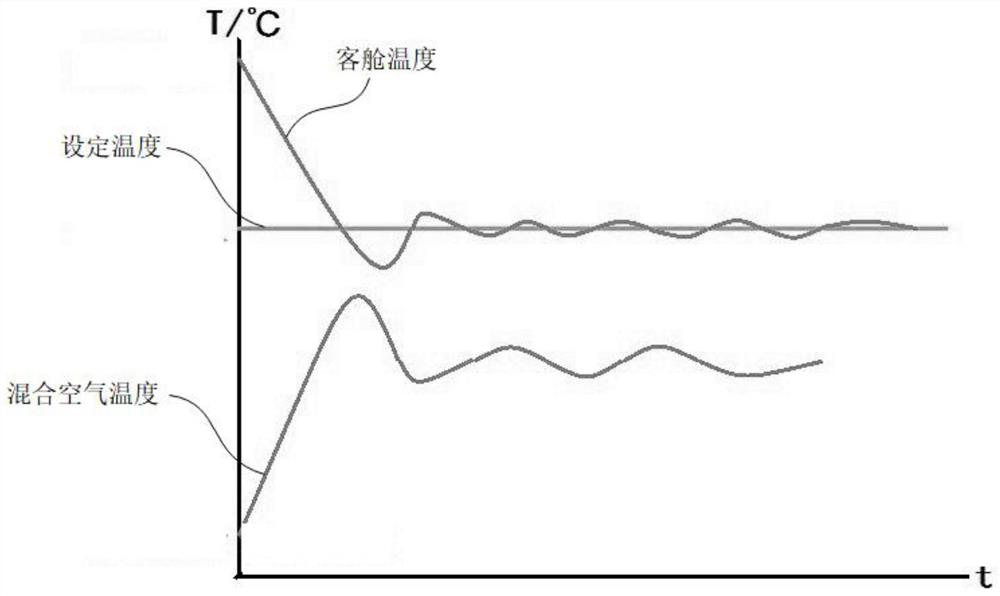

[0054] as attached figure 2 As shown, the schematic diagram of the conventional aircraft air conditioning system is described; when the aircraft engine is working, the outside air is sucked in, and after the action of the internal compressor, the pressure and temperature will rise significantly; the engine, auxiliary power components, or compressor are all It can be used as a heat source to generate hot air; high-pressure hot air with a temperature of 150°C to 200°C and a pressure of 30psi-50psi is drawn from the heat source; when the air conditioner is started, the temperature control computer controls the flow control valve to open, so that the high-pressure hot air enters the air conditioner components, The core components of the module are the heat exchanger and the air circulation machine. When the high-pressure hot air passes through the heat exchanger, a part of the heat is taken away by the external cold air, and the temperature decreases significantly, but the pressur...

Embodiment 2

[0087] This embodiment should be understood as including at least all the features of any one of the foregoing embodiments, and further improved on the basis thereof;

[0088] as attached Figure 5 shown, is an embodiment of the test segment;

[0089] Optionally, the outer surface of the test section 200 adopts a metal panel as the outer panel to provide a solid outer structure surface; Condensed water generated at low temperature of test section 200;

[0090] The inner surface material of the test section 200 is polyoxymethylene resin (POM), which is formed into a cube by direct molding and is embedded in the outer panel; POM is a linear type without side chains, high density and high crystallinity. Polymers, of which polyoxymethylene materials are preferably used; POM materials have high stiffness, good elasticity, and good wear resistance and wear resistance; their mechanical properties are excellent, with a specific strength of up to 50.5MPa and a specific stiffness of u...

Embodiment 3

[0099] This embodiment should be understood as including at least all the features of any one of the foregoing embodiments, and further improved on the basis thereof;

[0100] In the test section 200, the vibration device is also included; Figure 7 , is a schematic diagram of the temperature control device; wherein, the vibration device includes a horizontal vibrator and a vertical vibrator; the horizontal vibrator is in contact with the horizontal side of the pipe fittings in the test section 200 for generating Vibration in the horizontal direction; the vertical vibrator is arranged below the pipe fitting and is in contact with the pipe fitting to generate vertical vibration;

[0101] Preferably, the horizontal vibrator and the vertical vibrator comprise a casing and a vibrator part;

[0102] The casing includes an outer casing 708 and an inner casing 701; the inner casing 701 is a frame body with an open structure at the upper and lower parts; the inner casing 701 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com