Harvesting auxiliary mechanism of sugarcane harvester and sugarcane harvesting method of harvesting auxiliary mechanism

A harvester and cutting mechanism technology, applied to harvesters, agricultural machinery and implements, agriculture, etc., can solve problems such as poor mobility, waste of labor, and poor performance, so as to facilitate bundling or collection, improve work efficiency, and improve The effect of applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

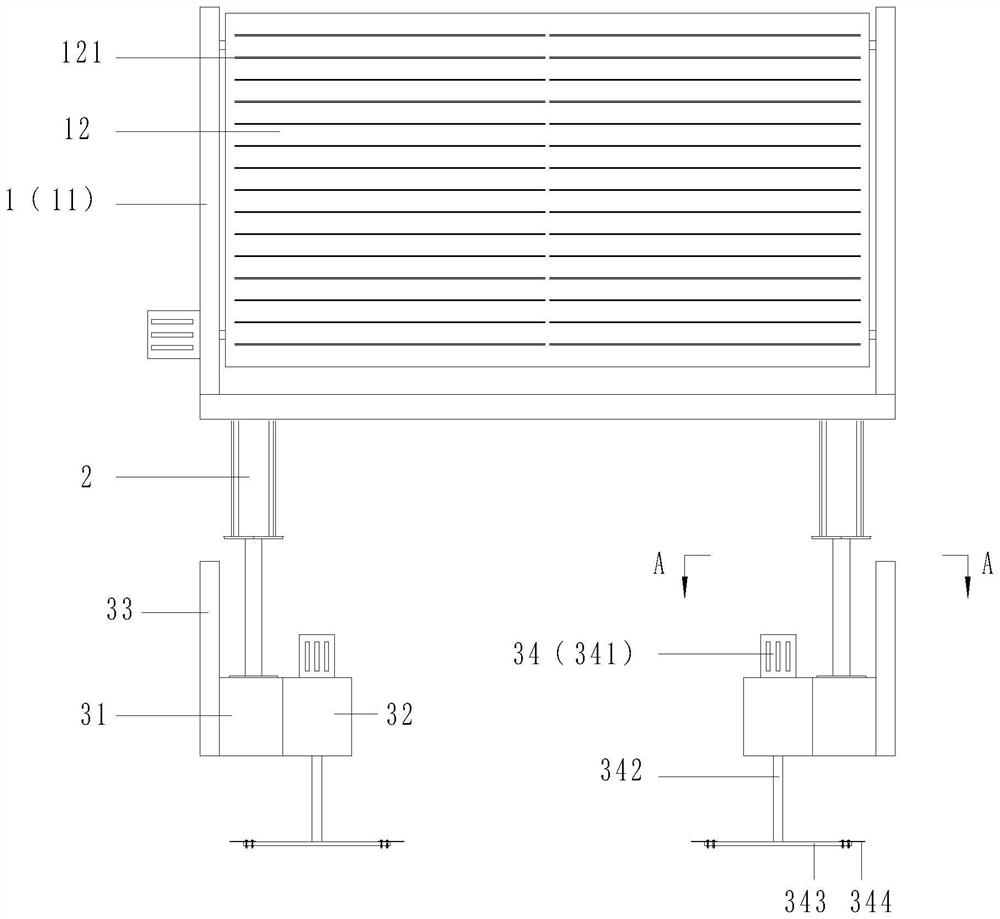

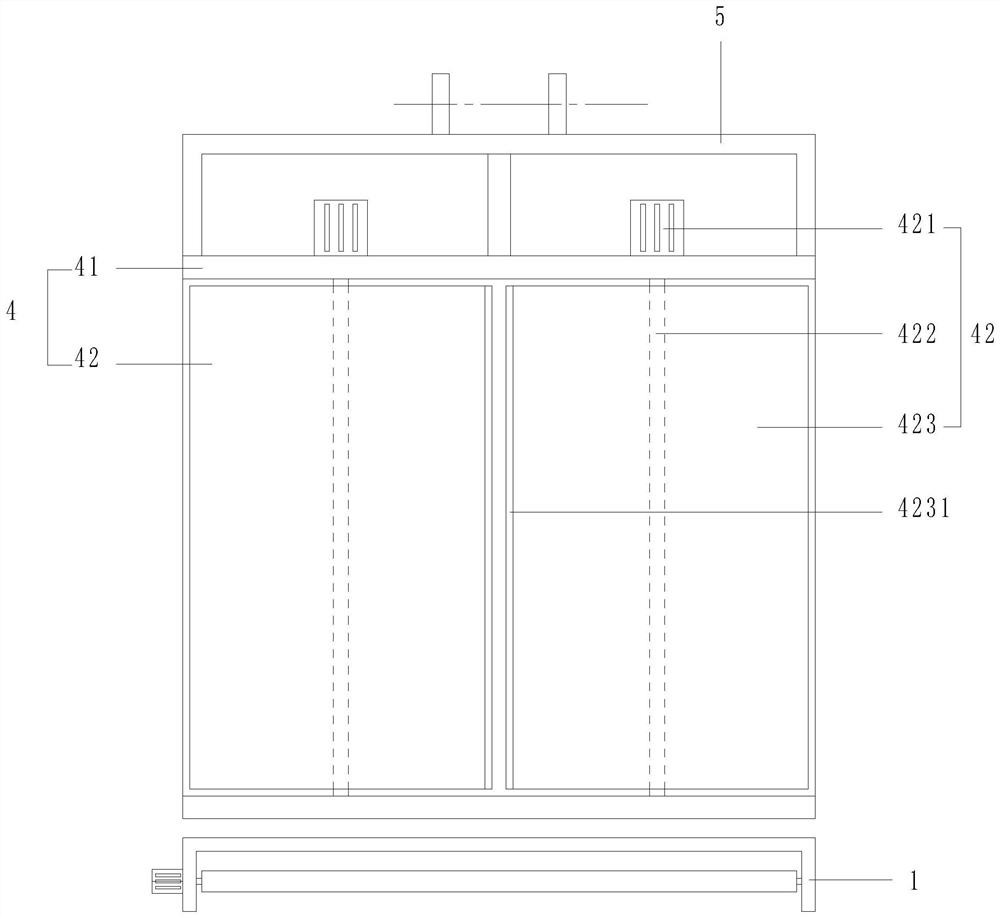

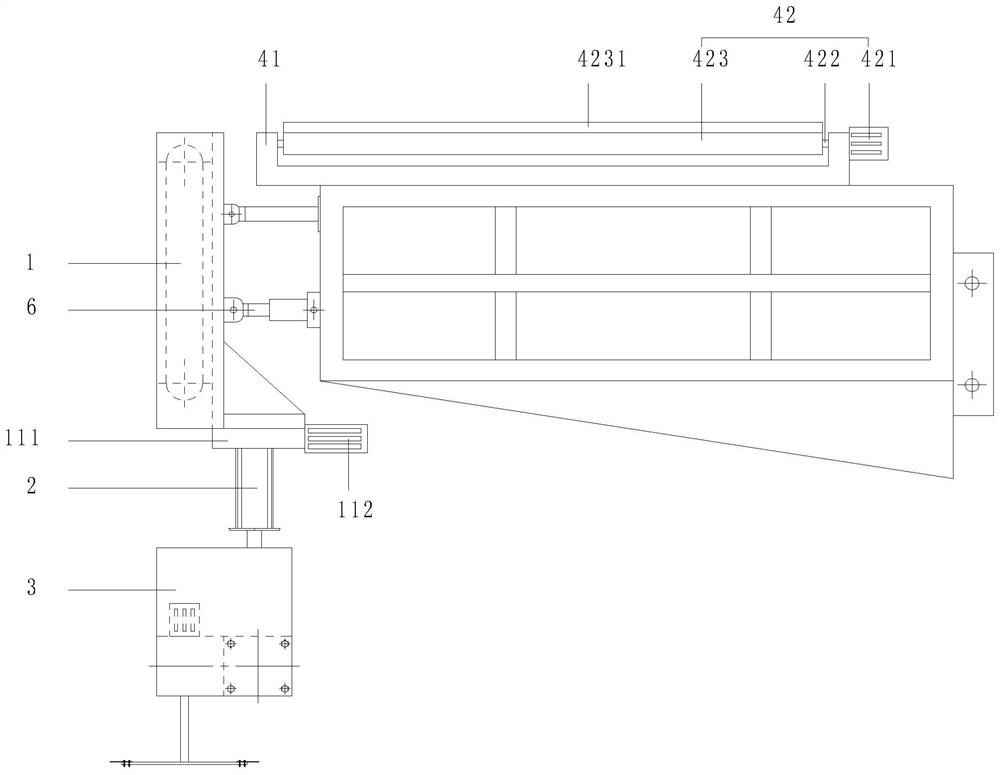

[0032] like Figure 1 to Figure 4 As shown in the figure, a harvesting auxiliary release mechanism of a sugarcane harvester includes a guide device 1, two height adjustment devices 2, two cutting devices 3, an auxiliary release device 4 and a frame 5, and the guide device 1 is vertically installed on the frame. 5 and is rotatably connected with the frame 5, two height adjustment devices 2 are installed at the lower end of the guide device 1 at intervals and are slidably connected with the guide device 1, and two height adjustment devices 2 are installed at one end away from the guide device 1 respectively. The cutting device 3 and the auxiliary placing device 4 are laterally installed above the frame 5 , and the auxiliary placing device 4 is arranged flush with the upper end of the guide device 1 .

[0033] In this embodiment, refer to figure 1 and figure 2 , the guide device 1 includes a base 11 and a transmission mechanism 12 , the base 11 has a U-shaped structure, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com