Integrated treatment process for glassine paper production wastewater

A technology for producing wastewater and glassine paper, which is applied in the process of wastewater treatment, sustainable biological treatment, water/sewage multi-stage treatment, etc. The effect of improved biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

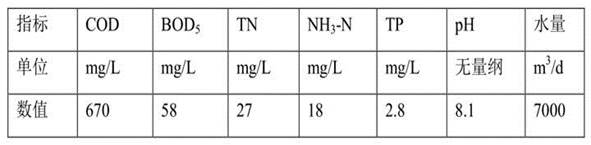

[0016] A special paper production enterprise produces glassine paper with a certain proportion of coniferous and hardwood pulp boards, and the waste water discharge per ton of product is 18m 3 , PVA consumption per ton of product is 5.5 kg, and enterprise wastewater discharge is 7000 m 3 / d, various pollution indicators of wastewater are shown in Table 1.

[0017] Table 1 Various water quality indicators of glassine paper production wastewater

[0018]

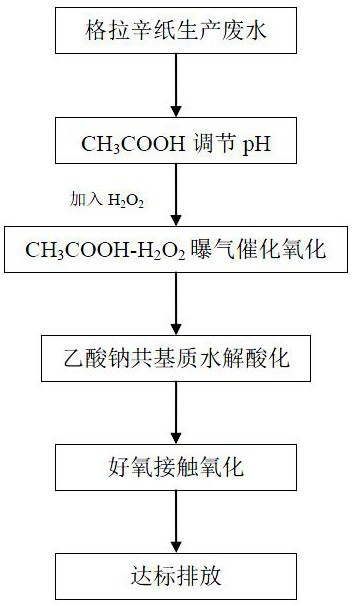

[0019] like figure 1 As shown, the integrated treatment process of glassine paper production wastewater in the present embodiment, the steps include

[0020] (1) pH adjustment of wastewater: the pH value of wastewater is 8.1, with CH 3 COOH adjusts the pH to 5.5~6.5.

[0021] (2) H 2 O 2 Dosing: H 2 O 2 (27.5% by mass) was added to the wastewater with pH of 5.5~6.5, taking 1L glassine paper production wastewater as the benchmark, and the amount of hydrogen peroxide added was 5%~10%wt of the COD content in the wastew...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap