Method for monitoring cut tobacco processing uniformity through DNA analysis and application thereof

A technology of uniformity and leaf shreds, which is applied in the direction of biochemical equipment and methods, microbial measurement/inspection, manufacturing calculation system, etc., can solve the problems of many detection indicators, evaluation of processing uniformity, long detection time, etc., and achieve the best results High accuracy, improved detection efficiency, and the effect of saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] The present embodiment provides a method for monitoring the uniformity of leaf silk processing by DNA analysis, the steps are as follows:

[0077] (1) during the normal production of shredded tobacco leaves, after the drying process, every 5min, randomly carry out 10 samplings, and the samples taken each time are evenly divided into 4 parts, and the samples after the sampling are numbered;

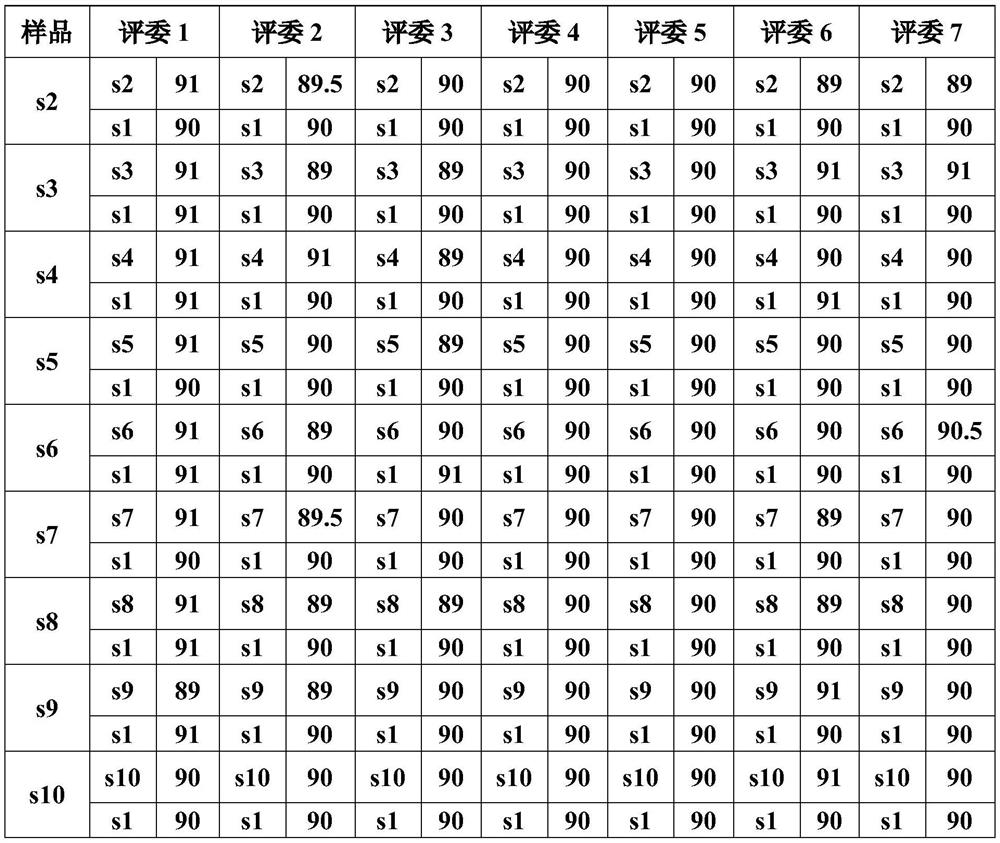

[0078] (2) Roll one of the cut leaf samples into a cigarette sample as a cigarette sample for sensory quality evaluation, organize personnel qualified for sensory quality evaluation in accordance with GB 5606.4-2005 "Cigarette Part 4: Sensory Technical Requirements" Sensory quality evaluation of cigarette samples;

[0079](3) Carry out chemical composition analysis on a part of the obtained leaf silk samples, and the leaf silk samples are based on YC / T468-2013, YC / T 159-2019, YC / T 161-2002, YC / T 217-2007 and YC / T 31-1996 standard methods for the determination of total plant alkaloi...

Embodiment 2

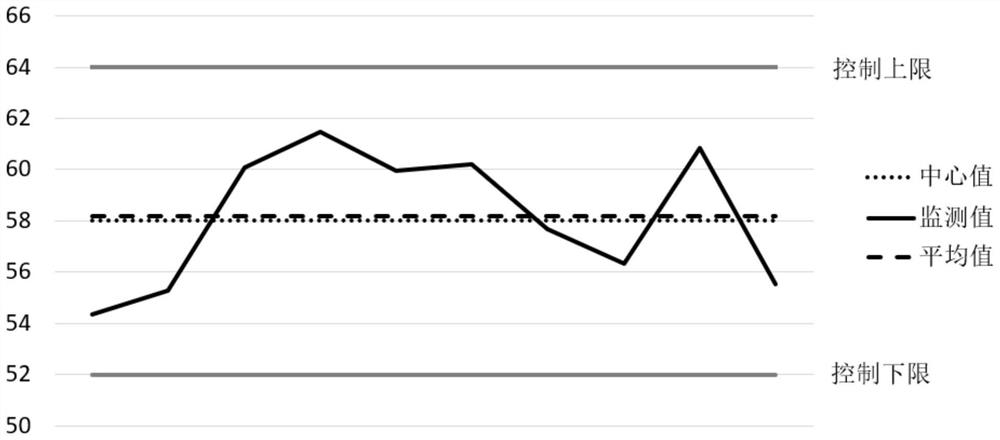

[0095] The only difference from Example 1 is that in this example, in step (6), the average DNA concentration value of the leaf silk sample ±3 times the standard deviation is used as the DNA concentration monitoring interval, and the remaining steps and methods are the same as those in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com