Axial force self-balancing multi-stage pump

An axial force and self-balancing technology, applied in the field of multi-stage pumps, can solve the problems of unstable liquid flow direction, consumption of motor bearing load, and easy formation of internal eddy currents, etc., to achieve stable and reliable pump operation, improve efficiency indicators, and service life long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

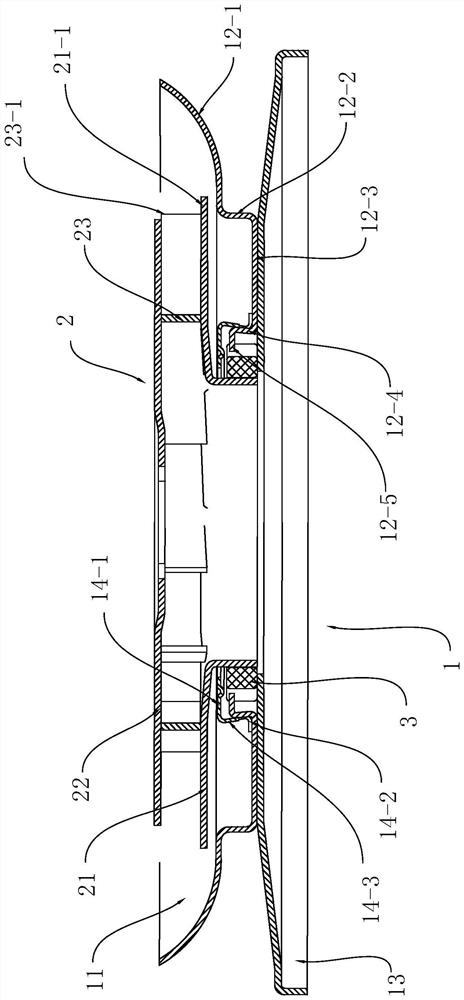

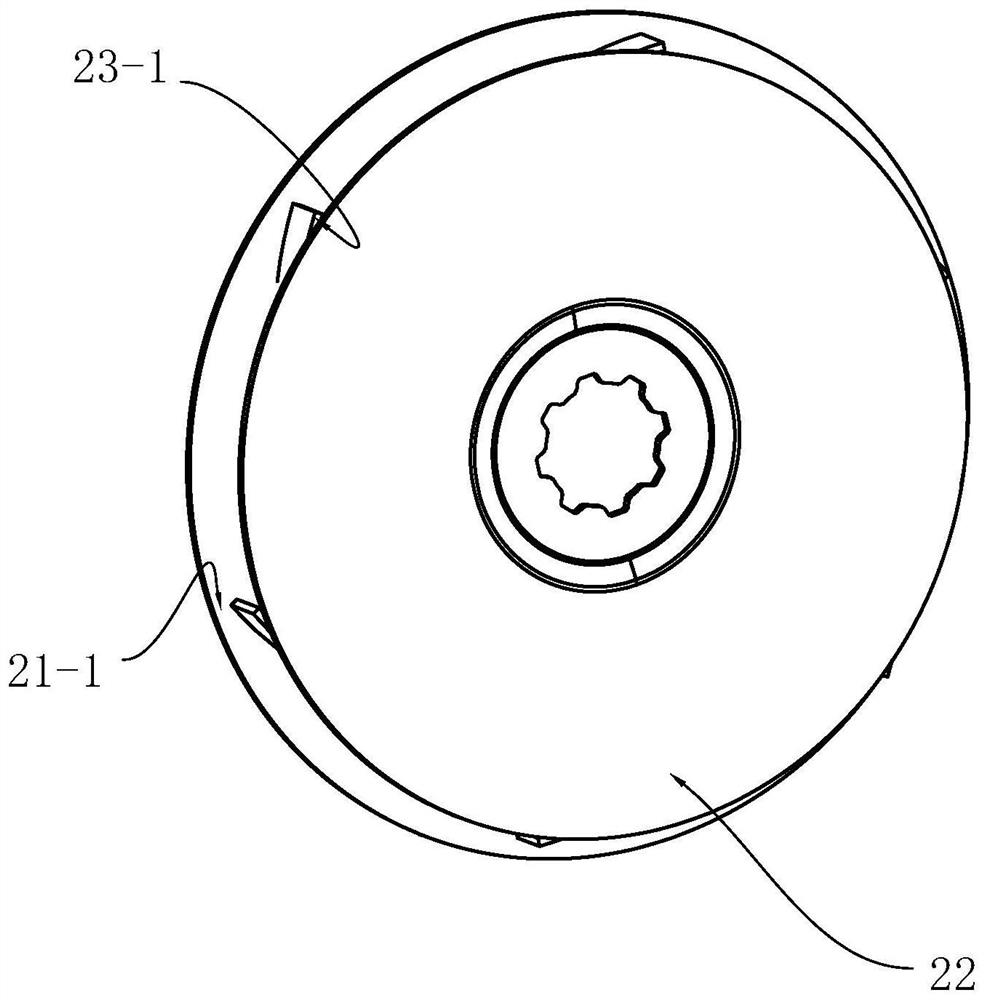

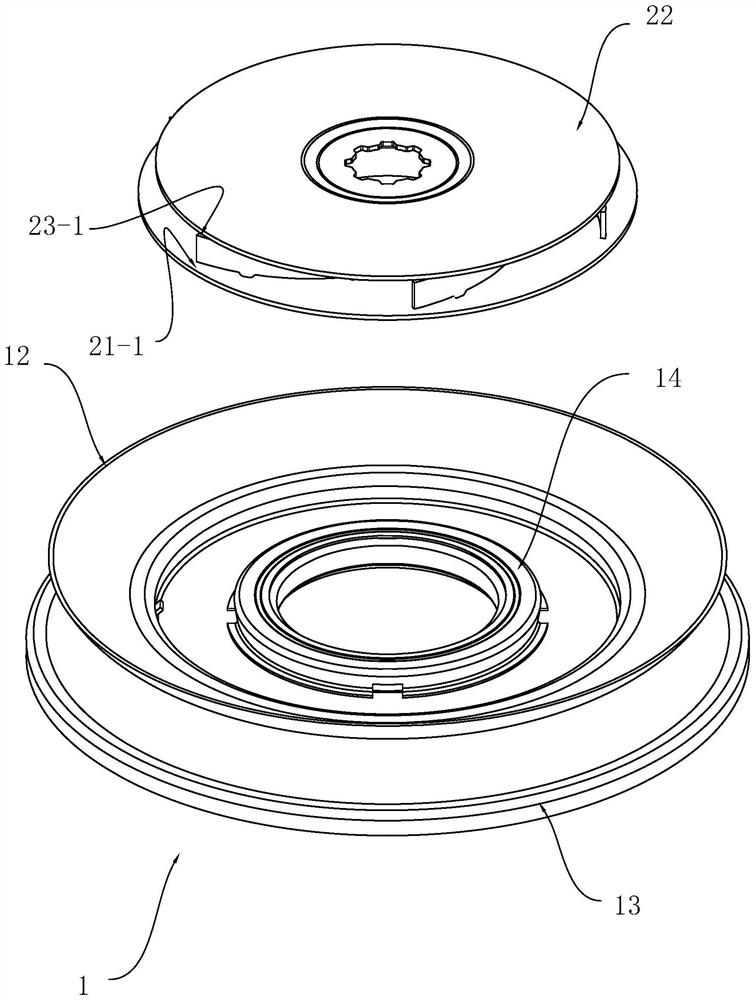

[0030] The technical solutions of the present invention will be further described in detail below through examples and in conjunction with the accompanying drawings.

[0031] Example: as Figure 1-4 As shown in the figure, the multistage pump with self-balancing axial force includes a pump body, an impeller string arranged in the pump body, and the impeller string is composed of several groups of impeller units. The impeller 2 in the guide cavity 11 of the shroud includes a front cover plate 21, a rear cover plate 22 and blades 23 arranged between the front cover plate and the rear cover plate. The outer diameter of the front cover is larger than the outer diameter of the rear cover, the front cover is matched with the bottom of the guide cavity, and the front cover is matched with the open part of the guide cavity.

[0032] The impeller with the area of the front cover plate is larger than that of the rear cover plate, and at the same time, it cooperates with the shroud to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com