Self-balancing loading device of high pressure gas environment material testing machine

A material testing machine and high-pressure gas technology, which is used in measuring devices, analytical materials, instruments, etc., can solve problems such as reducing control accuracy and service life, requiring high processing accuracy, and consuming the loading capacity of the mainframe of the testing machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

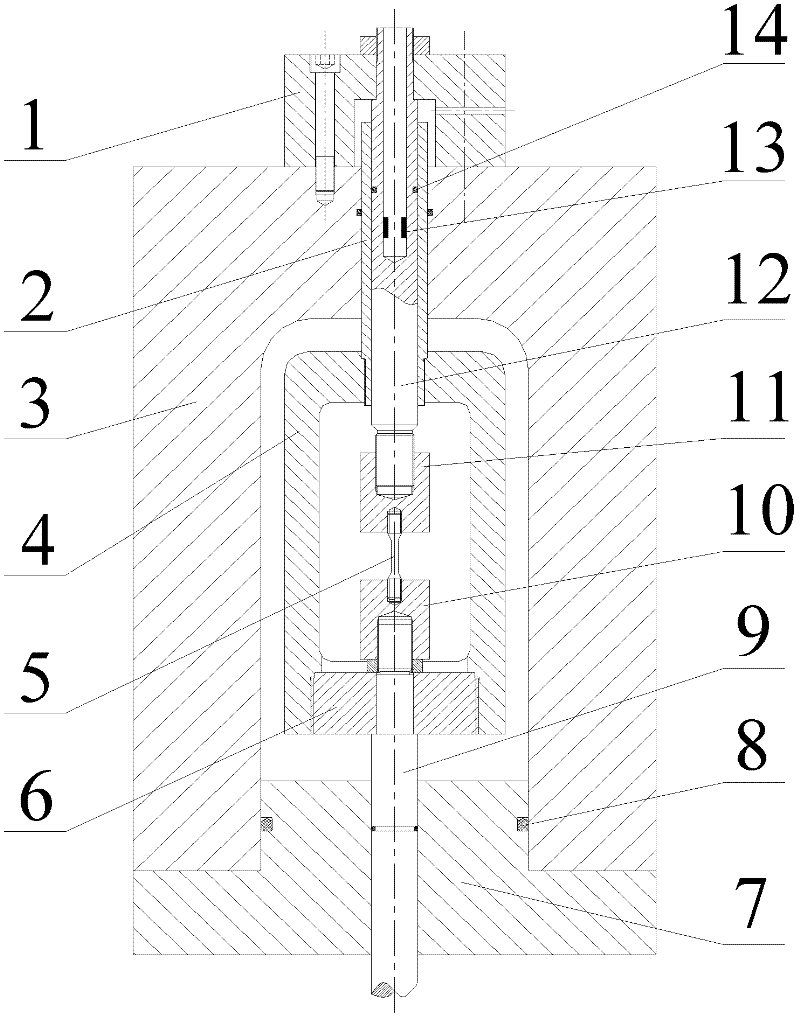

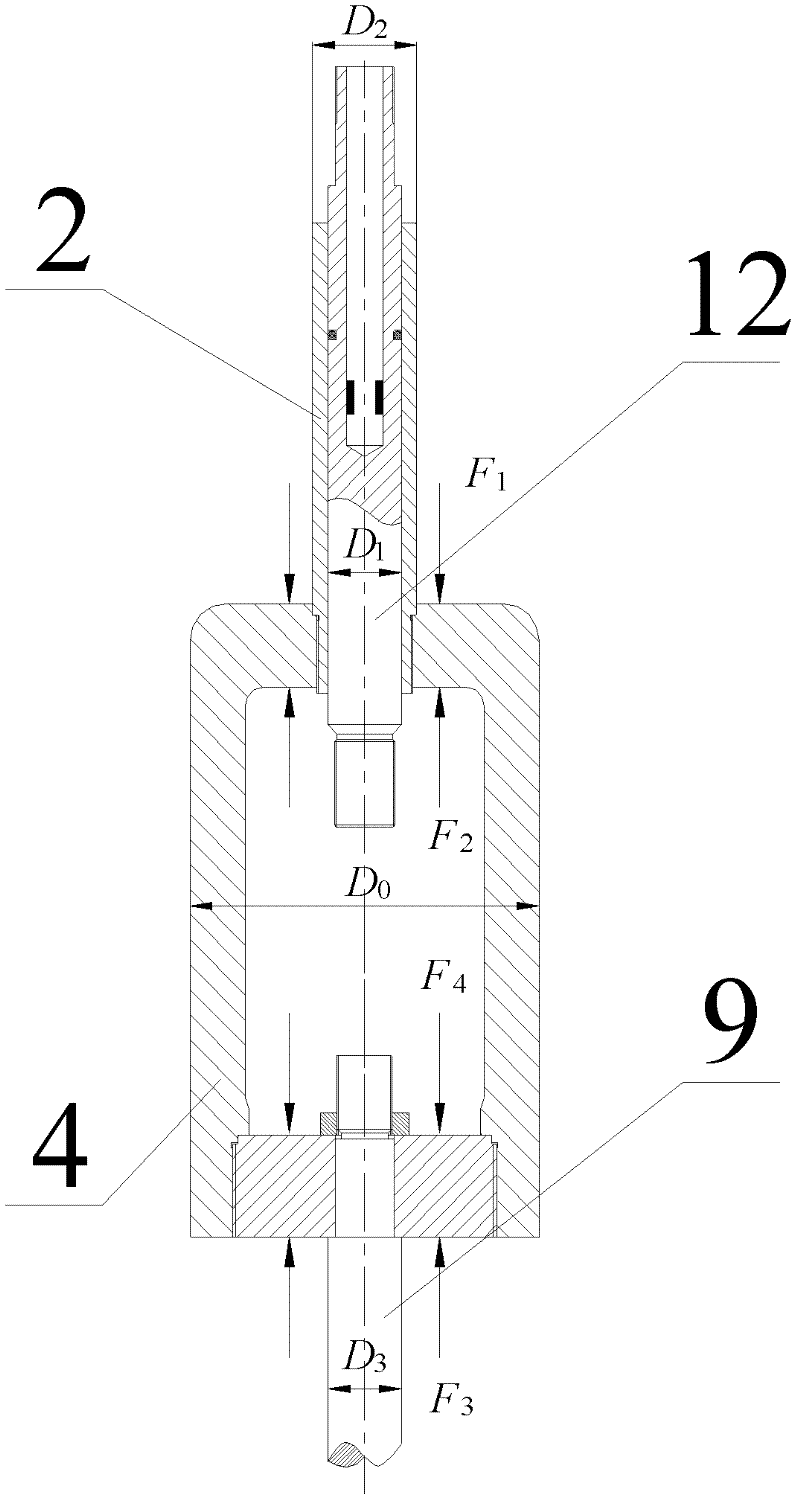

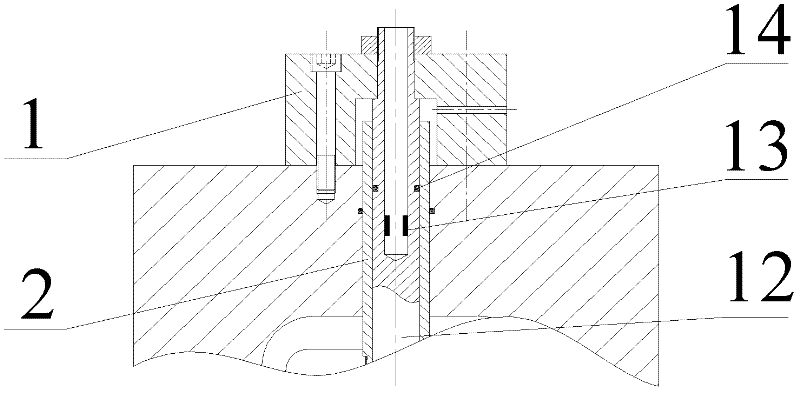

[0019] The loading device of the high-pressure gas environment material testing machine in this embodiment, such as figure 1 As shown, it includes balance sleeve 2, load transmission frame 4, disc 6, loading rod 9, sample lower clamp 10, sample upper clamp 11 and load measuring rod 12, etc., which are located in the environmental chamber body 3, the environmental chamber In the airtight high-pressure cavity formed by the sealing base 7 and the environmental box sealing assembly 8. One end of the loading rod 9 is connected to the power output end of the testing machine, the other end is connected to the load transmission frame 4 through the disc 6, and the other end of the load transmission frame 4 is connected to the balance sleeve 2 through a thread structure, and the balance sleeve 2 has a built-in load measuring rod 12. One end of the load measuring rod 12 is connected to the load measuring rod support 1 and fixed relative to the environment box body 3 , and the other end i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com