Product production task processing method and device, medium and program product

A production task and product technology, applied in the field of production and manufacturing, can solve the problems of not being able to meet the production demand and realize efficient streamlined production, and achieve the effect of efficient streamlined production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

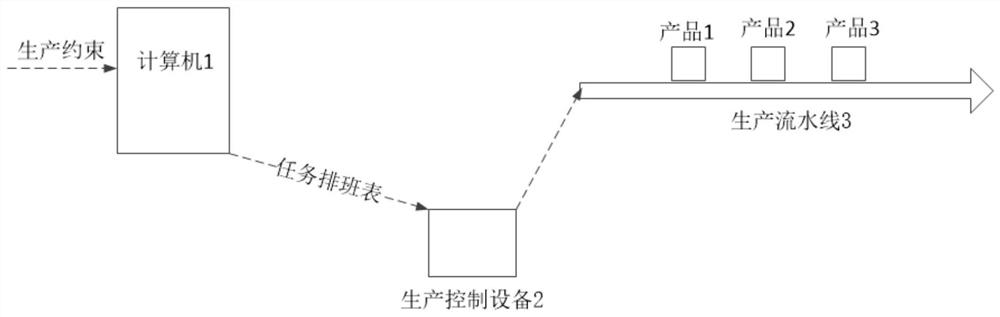

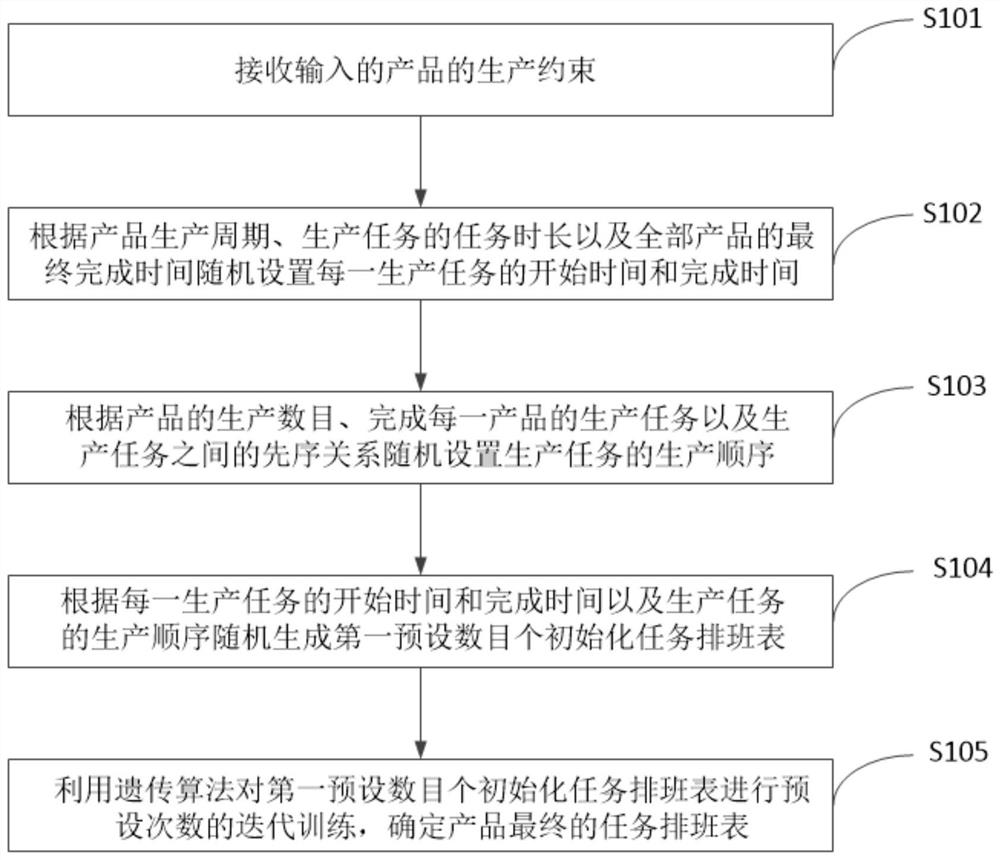

[0060] figure 2 This is a flowchart of a method for processing a production task of a product provided by an embodiment of the present application. The execution subject of the method for processing a production task of a product provided by an embodiment of the present application may be a production task processing device or a server. The main body is the production task processing device to describe the production task processing method of the product. like figure 2 As shown, the production task processing method of the product may include the following steps:

[0061] S101: Receive the input production constraints of the product, the production constraints of the product may include the production number of products, the production cycle of each product, the final completion time of all products, the production task for completing each product, and the corresponding production task for each production task. The task duration and the sequence relationship between the pr...

Embodiment 2

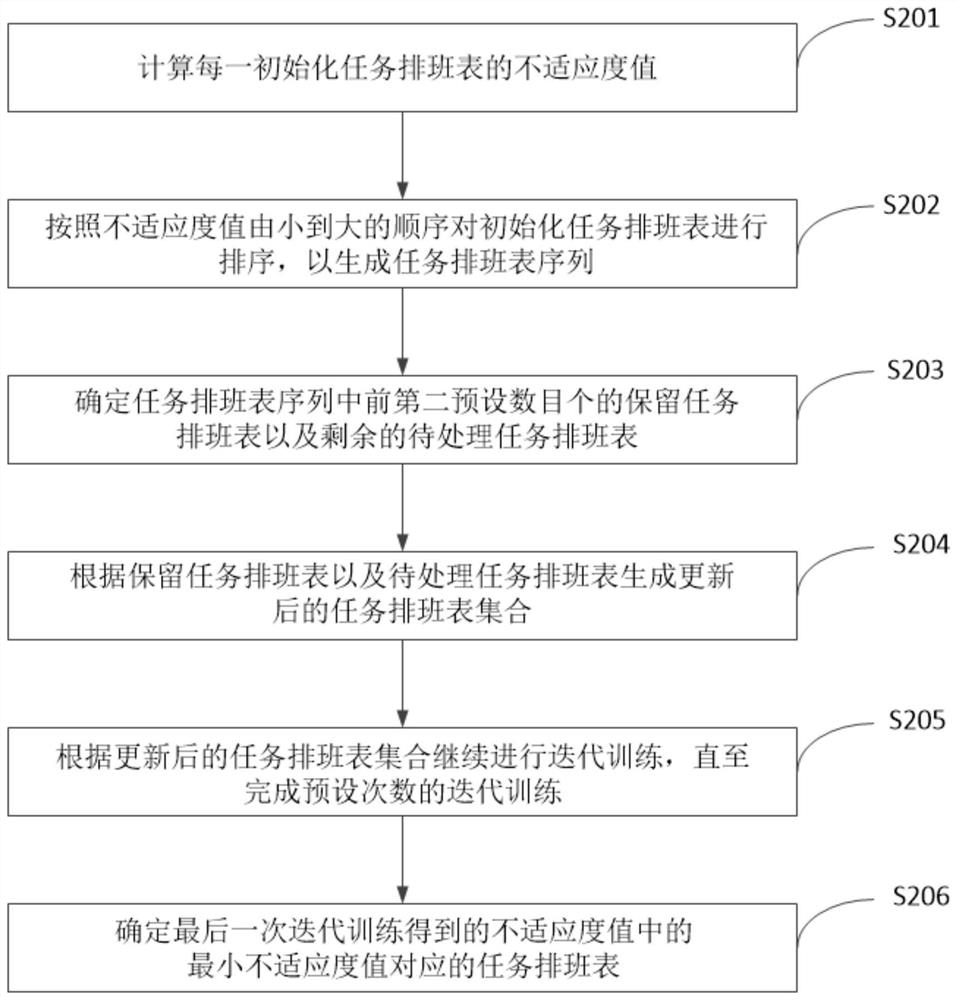

[0094] image 3 This is a flowchart of a method for processing a production task of a product provided by an embodiment of the present application. The execution subject of the method for processing a production task of a product provided by an embodiment of the present application may be a production task processing device or a server. The main body is the production task processing device to describe the production task processing method of the product. like image 3 As shown, the production task processing method of the product may include the following steps:

[0095] S201: Calculate the unfitness value of each initialization task schedule, and the unfitness value is set according to the production demand of the product.

[0096] In this embodiment, the unfitness value can be set according to the production demand of the product, for example, if the production demand of a certain product is the minimum required quantity of resources, then the unfitness value can be the t...

Embodiment 3

[0133] In a specific embodiment, a certain factory needs to complete the assembly line production of a certain number of aircraft, so the staff needs to set a specific task schedule of aircraft production work through a computer integrated with a production task processing device, and the specific steps are as follows:

[0134] The first step is to receive the production constraints of the product input by the staff, including the number of aircraft produced, the assembly cycle of an aircraft, the assembly completion time of all aircraft, the assembly tasks of an aircraft, and the tasks corresponding to each assembly task. The duration and the sequence relationship between the assembly tasks.

[0135] In the second step, the start time and completion time of each assembly task are randomly set according to the assembly cycle of one aircraft, the task duration corresponding to each assembly task, and the assembly completion time of all aircraft.

[0136] In the third step, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com