A flame-retardant gas-generating polyamide arc-extinguishing composite material and its preparation method and application

A composite material and polyamide technology, which is applied in the preparation of miniature circuit breakers, flame-retardant gas-producing polyamide arc-extinguishing composite materials and its preparation field, can solve the problem of less arc-extinguishing materials, and achieve excellent mechanical properties and gas pressure Obvious, the effect of lowering the thermal decomposition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

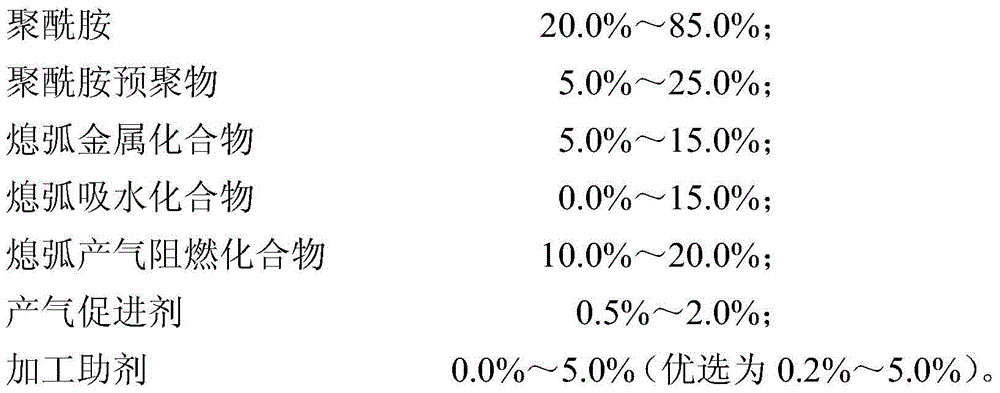

[0034] Use the following weights of ingredients:

[0035]

[0036] Stir and mix polyamide 66, polyamide 6 and heat stabilizer (1098, 168) evenly, and then feed them into the twin-screw extruder from a feeder with precision metering; Water-absorbing compound (sodium polyacrylate), arc-extinguishing gas-generating flame-retardant compound (melamine cyanurate) and gas-generating accelerator (potassium nitrate) are stirred evenly at high speed, and added from the precision metering feeder through the fourth section of the side feeding port Twin-screw extruder; the polyamide prepolymer is fed from the sixth section of the barrel by a liquid metering feeder, fully plasticized, melted, compounded, extruded, drawn, water cooled, pelletized and dried to obtain Polyamide composite materials; among them, the aspect ratio of the twin-screw extruder is 36:1, and the temperature of each section of the screw is: the temperature of each working section from the first barrel to the eighth b...

Embodiment 2

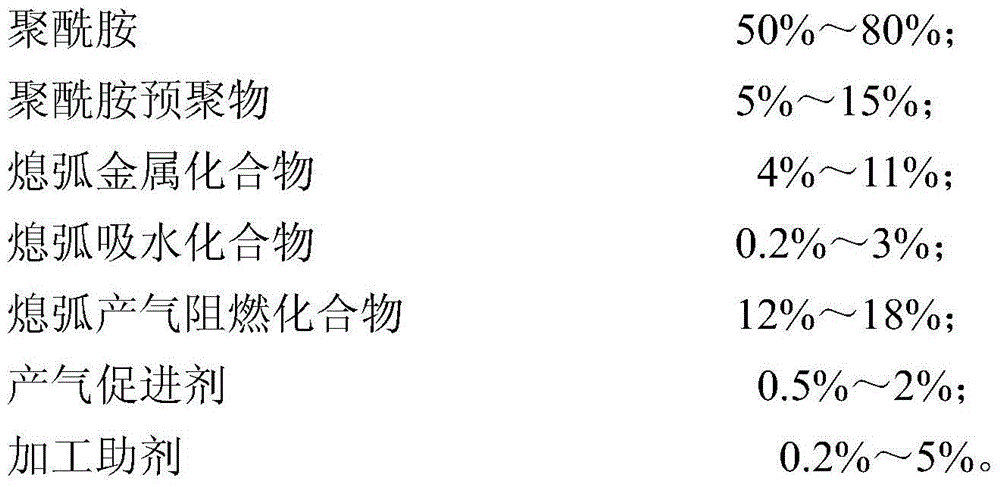

[0038] Use the following weights of ingredients:

[0039]

[0040] The preparation method of the polyamide composite material is the same as in Example 1, and the polyamide composite material is obtained. The temperature of each section of the screw is: the temperature of each working section from the first barrel to the eighth barrel is 240±5, 240±5, 240±5, 240±5, 230±5, 230±5, 230±5 , 230±5, the temperature of the head is 230±5℃.

Embodiment 3

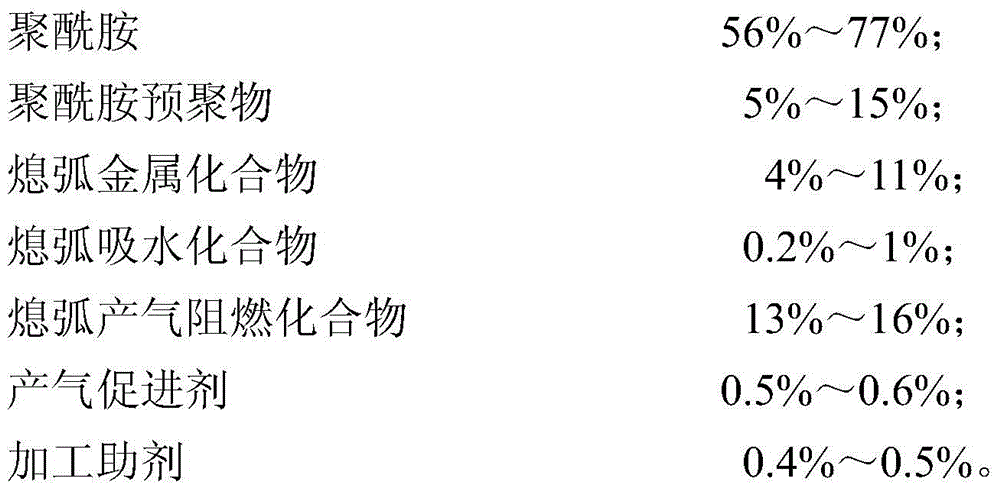

[0042] Use the following weights of ingredients:

[0043]

[0044]

[0045] The preparation method of the polyamide composite material is the same as in Example 1, and the polyamide composite material is obtained. The temperature of each section of the screw is: the temperature of each working section from the first section of the machine barrel to the eighth section of the machine barrel is 230 ± 5, 230 ± 5, 230±5, 230±5, 220±5, 220±5, 220±5, 220±5, the temperature of the machine head is 220±5℃.

PUM

| Property | Measurement | Unit |

|---|---|---|

| amine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com