Preparation method for titanium plate loaded palladium nanoparticle catalyst

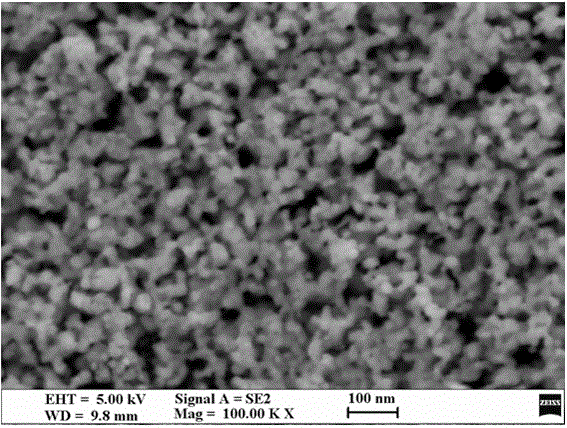

A catalyst, palladium nanotechnology, applied in the field of preparation of palladium nanocatalysts, can solve the problems of easy falling off of catalyst active substances, affecting catalytic performance, poor corrosion resistance, etc., and achieve the effects of uniform size, enhanced stability and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Etching the titanium plate in a boiling 20wt% oxalic acid solution for 1 hour, washing and drying with alcohol, and obtaining the etched titanium plate;

[0026] (2) Ultrasonically dissolve palladium acetate in absolute ethanol to obtain solution A with a concentration of 1g / 10mL; ultrasonically dissolve oleic acid in absolute ethanol to obtain solution B with a concentration of 1g / 10mL;

[0027] (3) Stir solution B, and add solution A dropwise to solution B, then stir and mix for 1 hour to obtain colloidal solution C; wherein the molar ratio of oleic acid to palladium acetate is 1:1;

[0028] (4) According to the coating amount of 1g / m 2 Apply colloidal solution C evenly on the etched titanium plate, put it in a drying oven, and dry at 60°C for 2 hours to obtain substance D;

[0029] (5) Put the substance D into a corundum ceramic boat, transfer it to a tube furnace, and pass in argon gas for protection, then raise the temperature to 180°C at a rate of 2°C / min at ...

Embodiment 2

[0032] (1) Etching the titanium plate in a boiling oxalic acid solution with a mass fraction of 60wt% for 2 hours, washing and drying with alcohol to obtain the etched titanium plate;

[0033] (2) Ultrasonically dissolve palladium dichloride in absolute ethanol to obtain solution A with a concentration of 1g / 10mL; ultrasonically dissolve potassium oleate in ethylene glycol to obtain solution B with a concentration of 1g / 10mL;

[0034] (3) Stir solution B, and add solution A dropwise to solution B, then stir and mix for 4 hours to obtain colloidal solution C; wherein the molar ratio of potassium oleate to palladium dichloride is 10:1;

[0035] (4) According to the coating amount of 10g / m 2 Apply colloidal solution C evenly on the etched titanium plate, put it in a drying oven, and dry at 60°C for 2 hours to obtain substance D;

[0036] (5) Put the substance D into a corundum ceramic boat, transfer it to a tube furnace, pass in nitrogen gas for protection, then raise the temper...

Embodiment 3

[0038] (1) Etching the titanium plate in a boiling oxalic acid solution with a mass fraction of 40wt% for 1 hour, washing and drying, to obtain the etched titanium plate;

[0039] (2) Ultrasonically dissolve sodium tetrachloropalladate in ethylene glycol to obtain solution A with a concentration of 1g / 10mL; ultrasonically dissolve sodium oleate in ethylene glycol to obtain solution B with a concentration of 1g / 10mL;

[0040] (3) Stir solution B, and add solution A dropwise to solution B, then stir and mix for 2 hours to obtain colloidal solution C; wherein the molar ratio of sodium oleate to sodium tetrachloropalladate is 5:1;

[0041] (4) According to the coating amount of 5g / m 2 Apply colloidal solution C evenly on the etched titanium plate, put it in a drying oven, and dry at 60°C for 2 hours to obtain substance D;

[0042] (5) Put the substance D into a corundum ceramic boat, transfer it to a tube furnace, and pass in nitrogen gas for protection, then raise the temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com