Ionic liquid surfactant containing ether functional groups and preparation method thereof

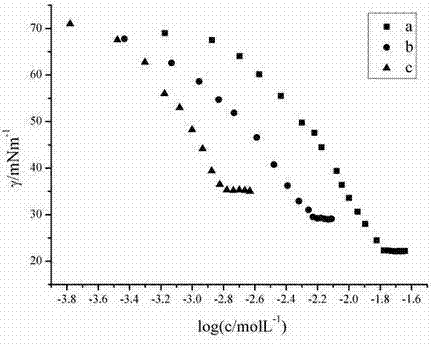

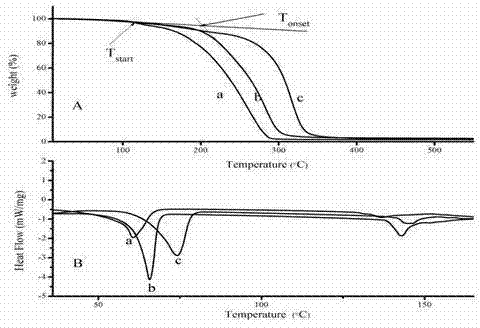

A surfactant and ionic liquid technology, applied in chemical instruments and methods, dissolution, organic chemistry, etc., can solve the problems of deep environmental pollution, high synthesis cost, high toxicity, etc., achieve low thermal decomposition temperature, easy adsorption, and reduce the surface tension effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

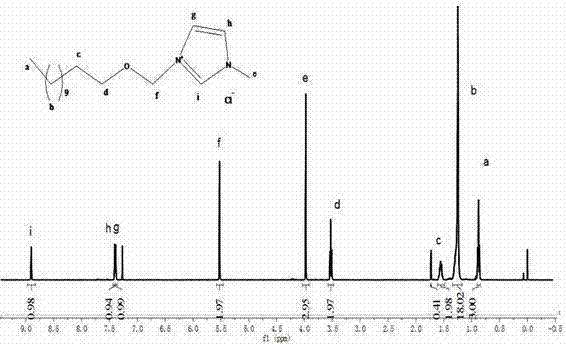

Method used

Image

Examples

Embodiment 1

[0017] The preparation of chloromethyl n-dodecyl ether: put a 250ml three-necked flask in an ice-water bath, first add 80.5mmol of n-dodecyl alcohol, add 80ml of n-hexane as a solvent, add 29.1mmol of paraformaldehyde, keep stirring, and then add Pass into the three-necked flask the hydrogen chloride gas produced by dripping concentrated sulfuric acid into hydrochloric acid at a rate of 1 drop / 20s, magnetically stir in an ice-water bath for 3 hours, and the reaction is completed, filter, and then distill under reduced pressure to remove the solvent n-hexane;

[0018] Add water-removed 1,1,1-trichloroethane to the prepared chloromethyl n-dodecyl ether, and 1,1,1-trichloroethane is used as the reaction solvent for the second step. Condensing device, under the condition of magnetic stirring at ≤ 5°C, slowly drop 98.6mmol of N-methylimidazole that has been dehydrated, and the reaction is over for 1 hour;

[0019] The solvent 1,1,1-trichloroethane was distilled off under reduced pr...

Embodiment 2

[0022] The preparation of chloromethyl n-tetradecyl ether: put the 250ml three-necked flask in the ice-water bath, add 94.6mol n-tetradecyl alcohol first, add 85ml n-hexane as solvent, add 41.6mmol paraformaldehyde, keep stirring, and then add Pass into the three-necked flask the hydrogen chloride gas produced by dripping concentrated sulfuric acid into hydrochloric acid at a rate of 1 drop / 20s, magnetically stir in an ice-water bath for 3 hours, and the reaction is completed, filter, and then distill under reduced pressure to remove the solvent n-hexane;

[0023] Add water-removed 1,1,1-trichloroethane to the prepared chloromethyl n-tetradecyl ether, and 1,1,1-trichloroethane is used as the reaction solvent for the second step. Condensing device, under the condition of magnetic stirring at ≤ 5°C, after slowly adding 121.8mmol of N-methylimidazole that has been dehydrated, the reaction is over for 1 hour;

[0024] The solvent 1,1,1-trichloroethane was distilled off under reduc...

Embodiment 3

[0026] Preparation of chloromethyl n-decyl ether: Put a 250ml three-necked flask in an ice-water bath, first add 126.3mmol of n-decyl alcohol, add 85ml of n-hexane as a solvent, add 34.1mmol of paraformaldehyde, keep stirring, and then pour into the three-necked flask Add hydrogen chloride gas generated by dropping concentrated sulfuric acid into hydrochloric acid at a rate of 1 drop / 20s, magnetically stir in an ice-water bath for 3 hours to complete the reaction, filter, and then distill under reduced pressure to remove the solvent n-hexane;

[0027] Add water-removed 1,1,1-trichloroethane and 1,1,1-trichloroethane to the prepared chloromethyl n-decyl ether as the reaction solvent for the second step, and turn on the condensation device, under the condition of magnetic stirring at ≤ 5°C, after slowly adding 151.56 mmol of N-methylimidazole from which water has been removed, the reaction was completed for 1 hour;

[0028] The solvent 1,1,1-trichloroethane was distilled off und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com