Ball part cleaning device and method for mechanical manufacturing

A technology of machinery manufacturing and cleaning device, applied in the field of machinery, can solve the problems of insufficient cleaning of parts, low cleaning efficiency, difficult classification, etc., to meet the needs of use, reduce labor intensity, and facilitate classification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

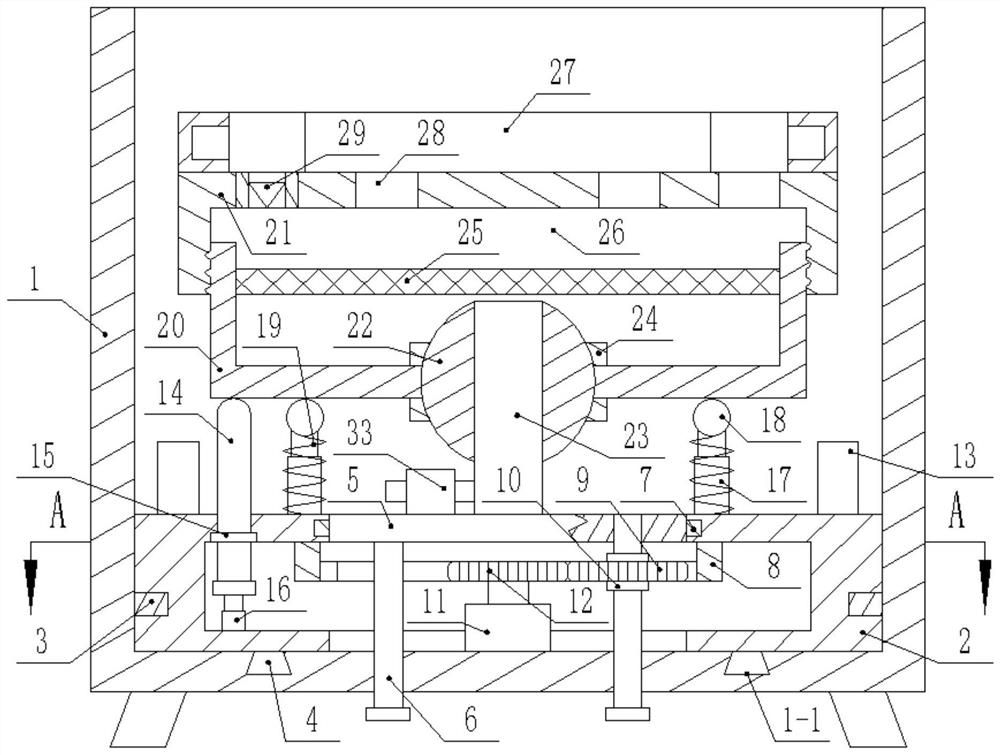

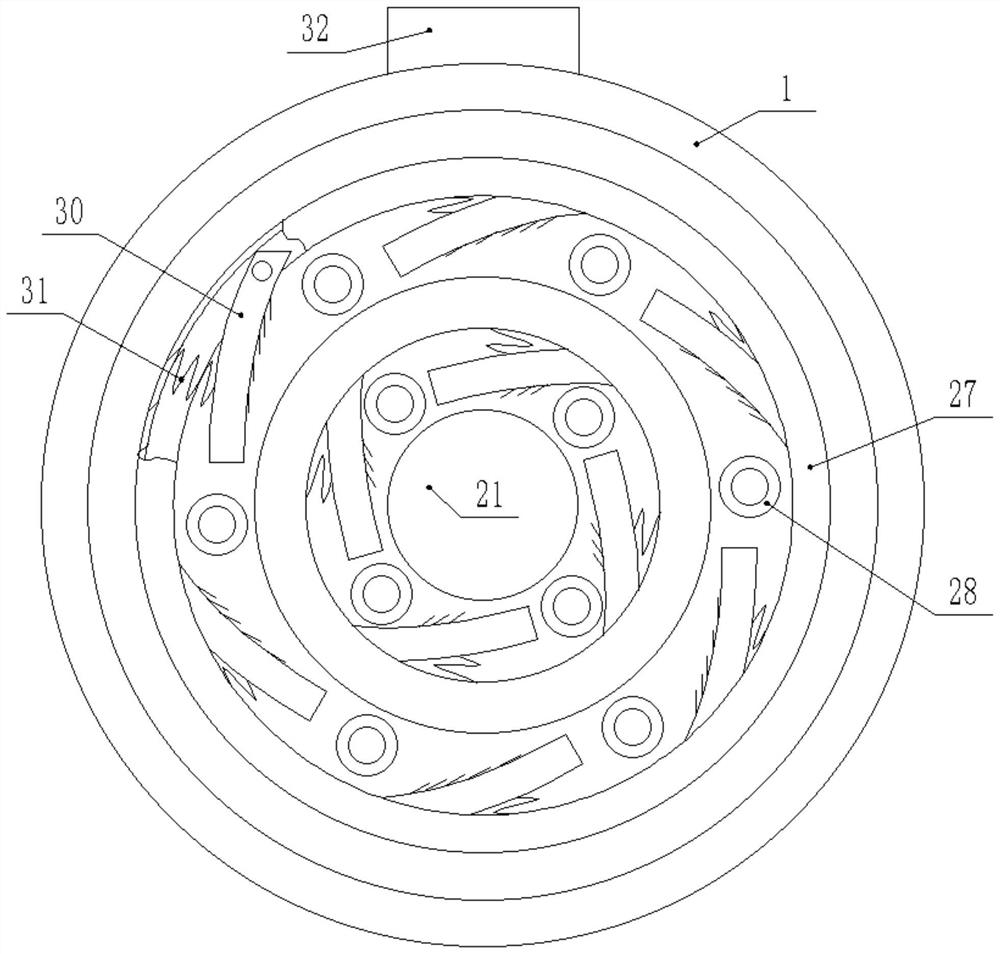

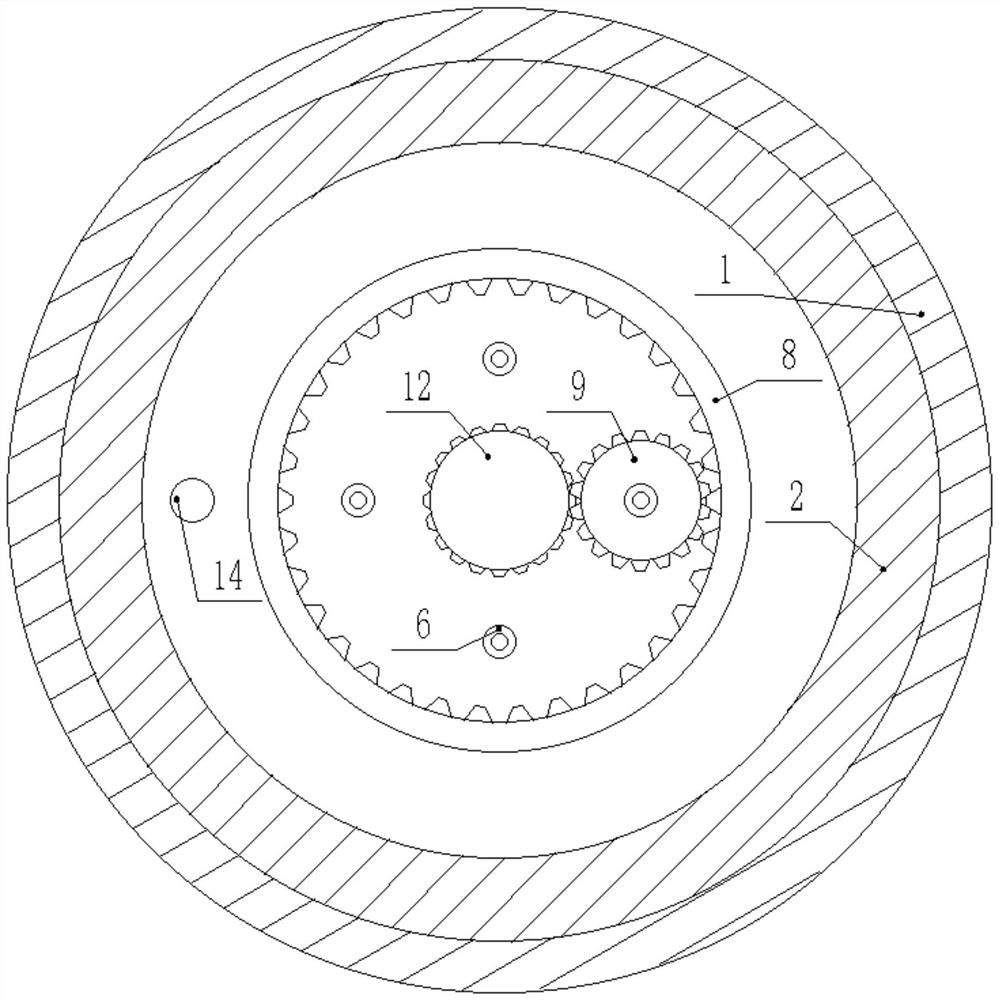

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments:

[0036] like figure 1 , figure 2 , image 3 , Figure 4 As shown, a device for cleaning ball parts for machinery manufacturing includes a mixing barrel 1, and a plurality of legs are fixedly and symmetrically connected to the bottom surface of the mixing barrel 1.

[0037] The inner bottom surface of the mixing barrel 1 is fitted and rotated with a first annular cylinder 2 , and the outer wall of the first annular cylinder 2 is fixed and embedded with a first sealing ring 3 through glue.

[0038] A dovetail groove 1-1 is annularly formed on the inner bottom surface of the mixing barrel 1, and a dovetail block 4 is fitted and slid in the dovetail groove 1-1.

[0039] A disc 5 is fitted and rotated in the first annular cylinder body 2, the top surface of the disc 5 is fixedly connected with a plurality of sewage pipes 6, and the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com