Tube cavity cleaning scraper

A technology of scraper and lumen, which is applied in the field of lumen cleaning and scraper, which can solve the problems of unfavorable disinfection, human health hazards, scratches, etc., and achieve good stain removal effect, fine overall structure, and good scraping coverage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

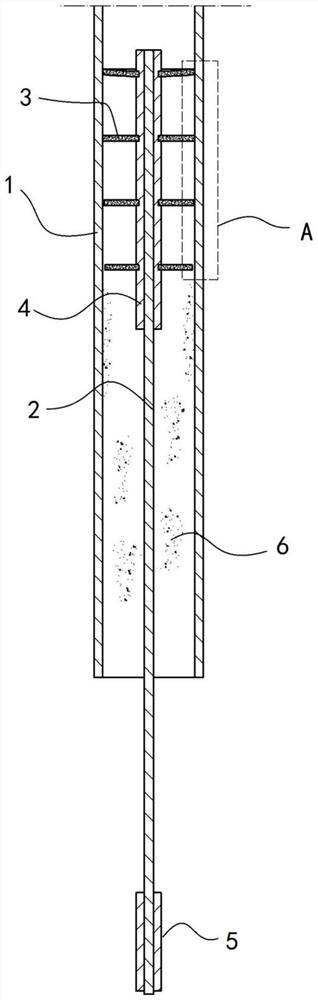

[0029] like figure 1 As shown, a lumen cleaning scraper includes a guide wire 2 and several scrapers 3 .

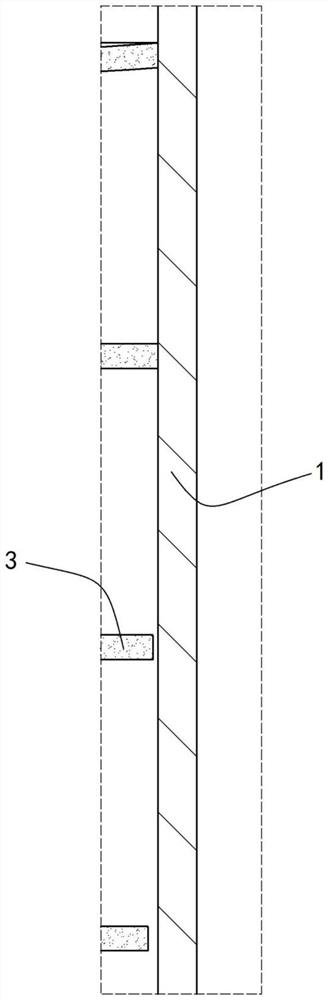

[0030] The guide wire 2 includes a scraping section and a holding section, and a plurality of the scraping blades 3 are distributed on the scraping section at intervals.

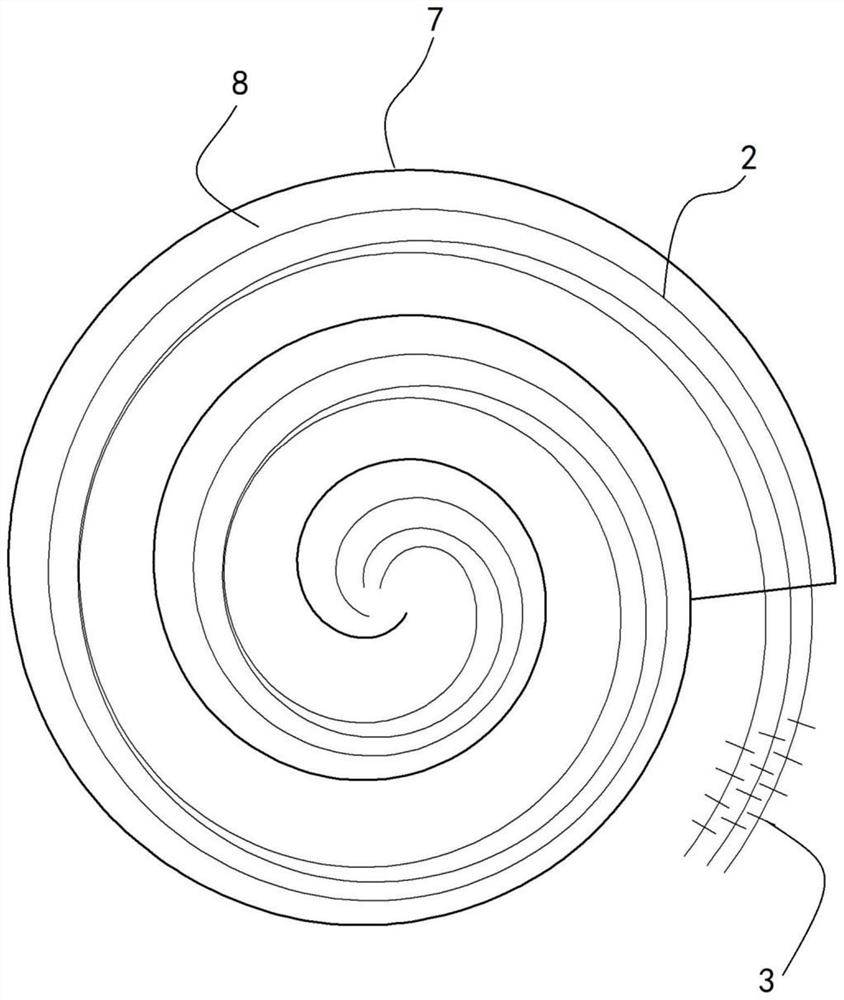

[0031] combine figure 2 As shown, the circular diameter of the scraper 3 gradually increases from the proximal end of the guide wire 2 to the distal end.

[0032] When in use, the scraper 3 of the scraping section is used to scrape the stains 6 , and the holding section is used to pull the guide wire 2 . When in use, the holding section is inserted through one end of the lumen 1 and pulled out from the other end of the lumen 1. During the process of pulling out the guide wire 2, the scraper 3 will scrape off the stains 6 on the inner wall of the lumen 1. Since the diameter of the scraper 3 gradually increases from the proximal end to the distal end of the guide wire 2, that is, with each scraper 3 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com