Universal spherical hinge rubber support applied to assembly type bent slope inclined road beam bridge

A universal ball joint and rubber bearing technology, which is applied in bridges, bridge construction, bridge parts, etc., can solve problems such as service life mismatch, bridge deck girder plate disease, and bearing service life reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the objectives, technical solutions and advantages of the present invention clearer, the invention will be clearly and completely described below with reference to specific embodiments.

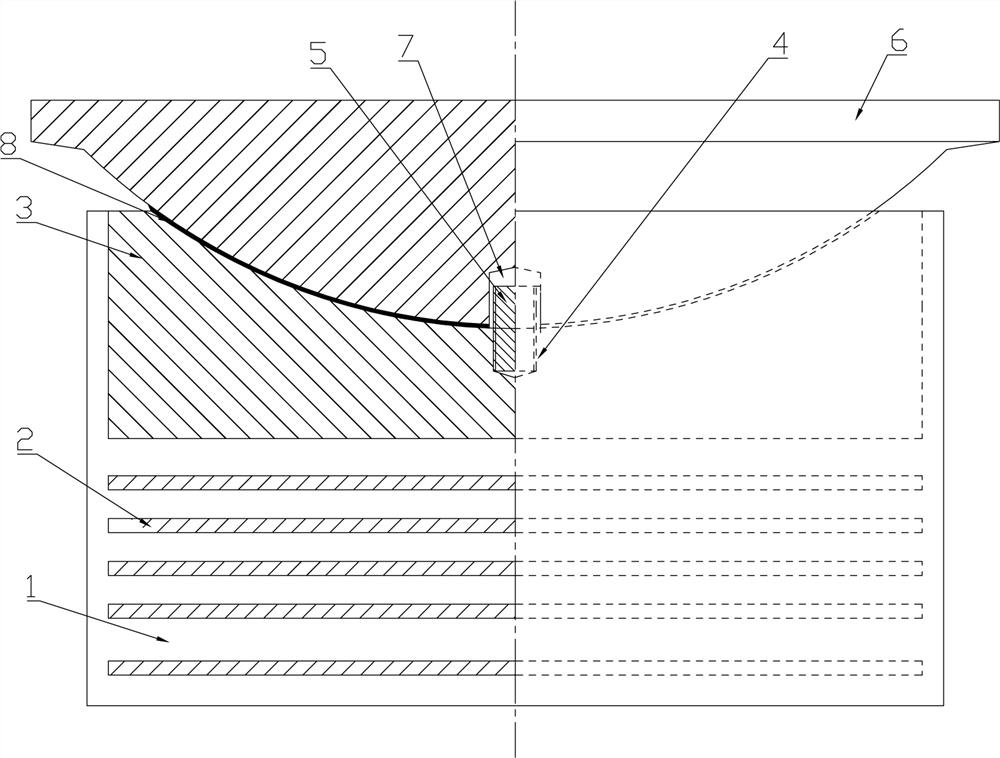

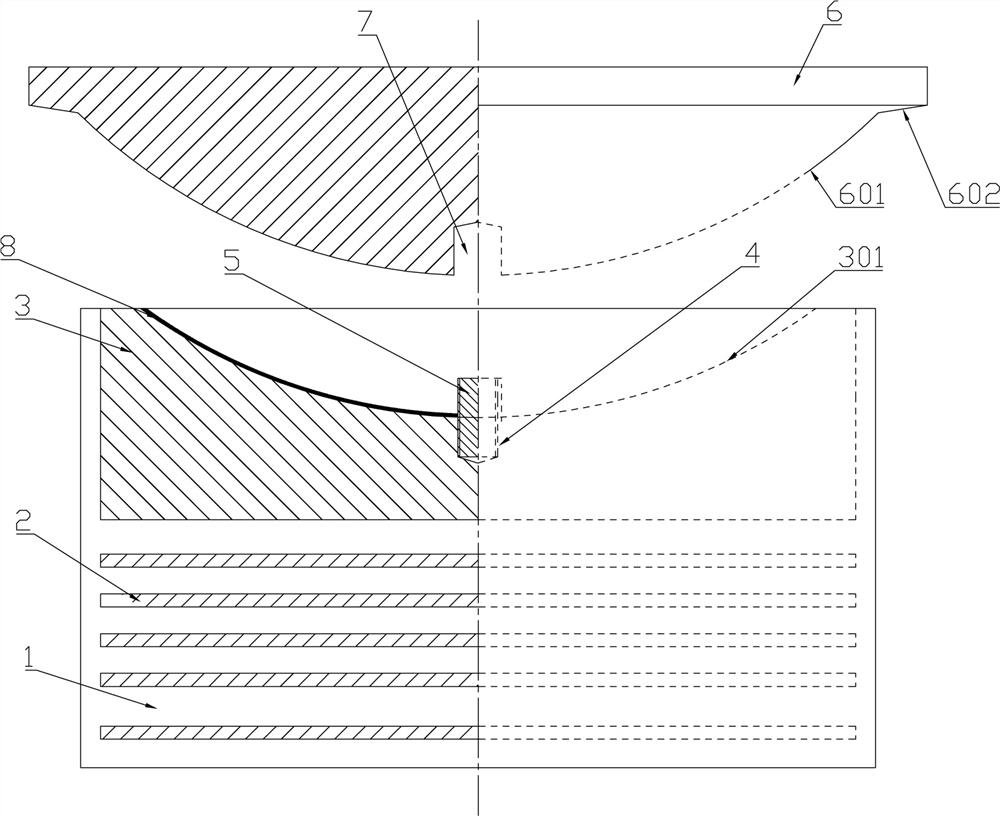

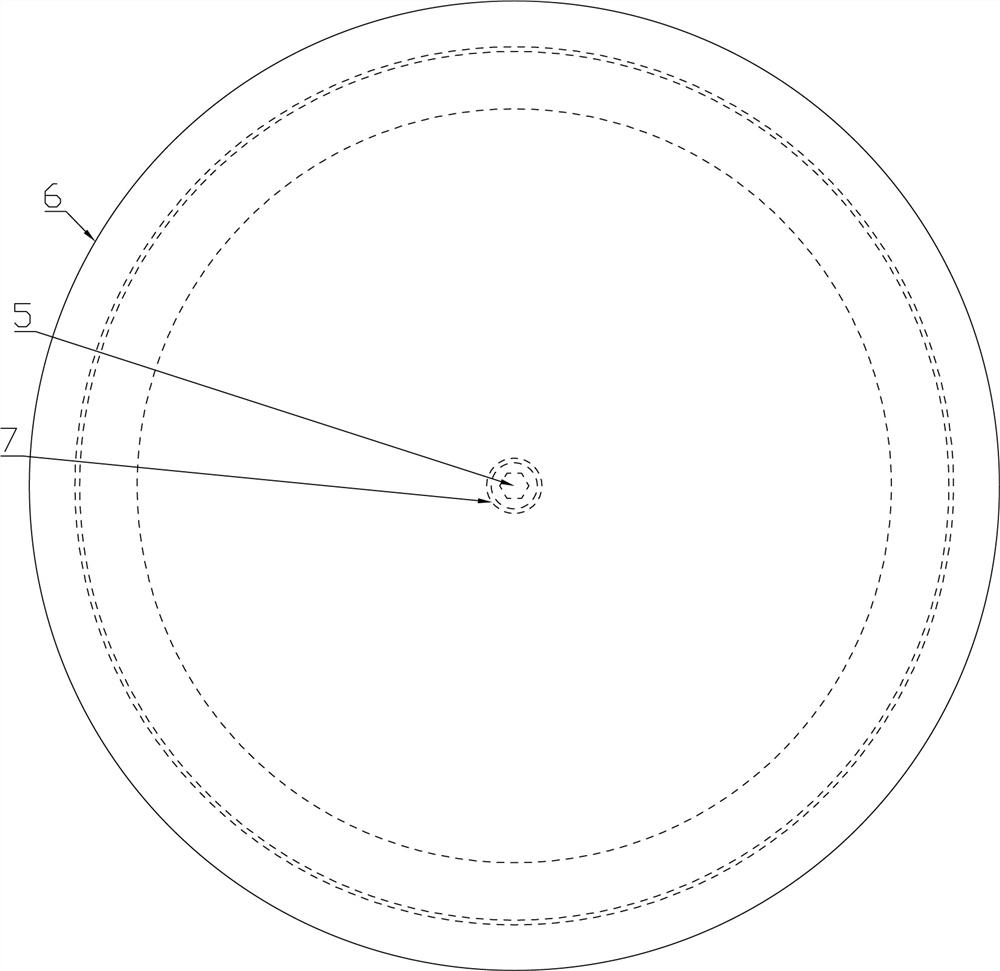

[0025] like Figure 1-Figure 3 Shown is a universal spherical hinge rubber bearing applied to an assembled curved slope inclined highway girder bridge, which includes a lower bearing and an upper bearing, and the lower bearing includes a rubber matrix 1, which is evenly embedded in the rubber matrix 1. A plurality of horizontal steel plates 2 at the lower part and a concave steel ball joint seat 3 arranged on the upper part of the rubber base 1, the middle of the top surface of the concave steel ball joint seat 3 is provided with a concave spherical surface 301; the upper support is convex The bottom surface of the shaped steel ball hinge seat 6 is provided with a convex spherical surface 601 that matches the concave spherical surface 301 . The universal spherical joi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com