Environment-friendly dustproof filter cloth for chemical factory and mounting method of environment-friendly dustproof filter cloth

An environmentally friendly, filter cloth technology, applied in chemical instruments and methods, separation methods, filtration and separation, etc., can solve the problems of small air contact area, poor filtration effect, difficult to hold up, etc., to prolong the cleaning cycle and improve the filtration effect. , the effect of large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

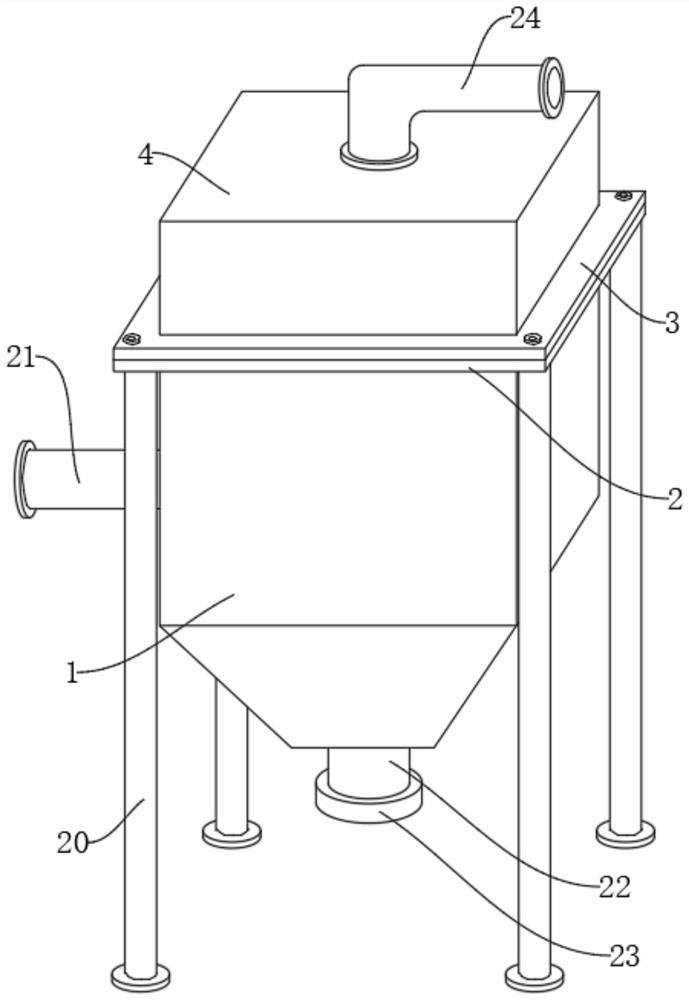

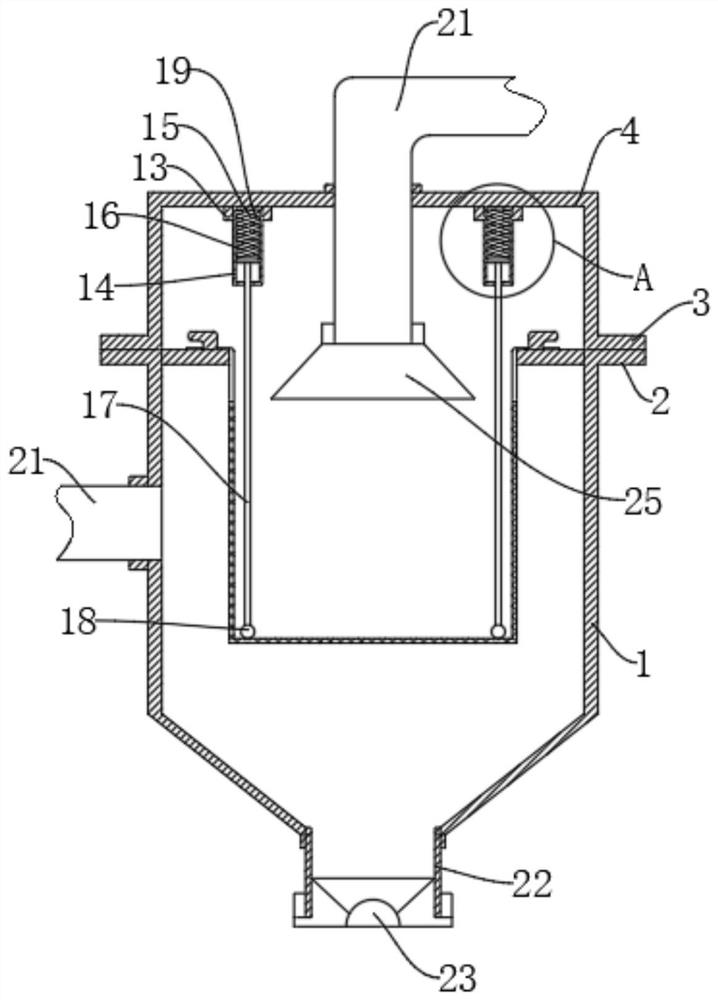

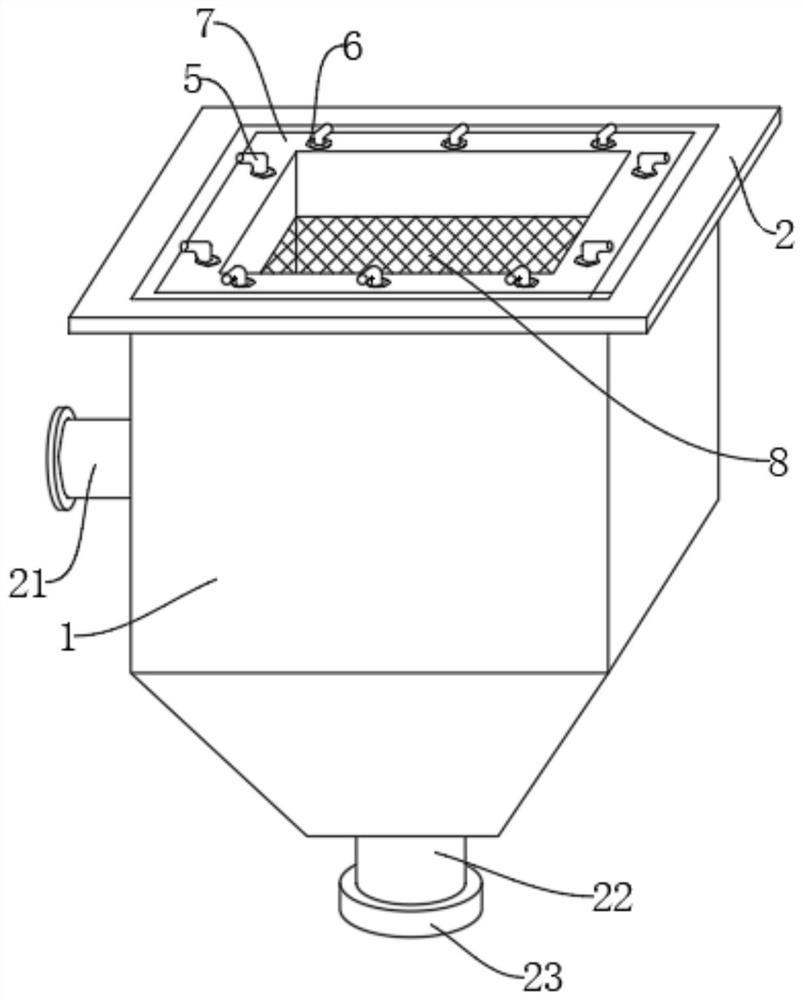

[0026] The present invention will be further described below in conjunction with the accompanying drawings:

[0027] like Figure 1-Figure 7 As shown in the figure, an environmentally friendly dust-proof filter cloth for chemical plants includes a lower casing 1, an upper casing 4 and a filter cloth 8. The upper end of the lower casing 1 is welded with a first connecting plate 2, and the upper end of the first connecting plate 2 is provided with There is a second connecting plate 3, an upper casing 4 is arranged in the middle of the upper end of the second connecting plate 3, a hook 5 is arranged on the periphery of the upper end of the first connecting plate 2 in the upper casing 4, and a hanging ring 6 is arranged on the periphery of the hook 5. An elastic cloth cover 7 is arranged on the periphery of the ring 6, and a filter cloth 8 is arranged at the lower end of the elastic cloth cover 7. The filter cloth 8 includes a synthetic fiber layer 9, a absorbent cotton cloth laye...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap