Waste gas treatment device with deodorization function

A waste gas treatment device and functional technology, applied in the field of waste gas treatment devices with deodorization function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

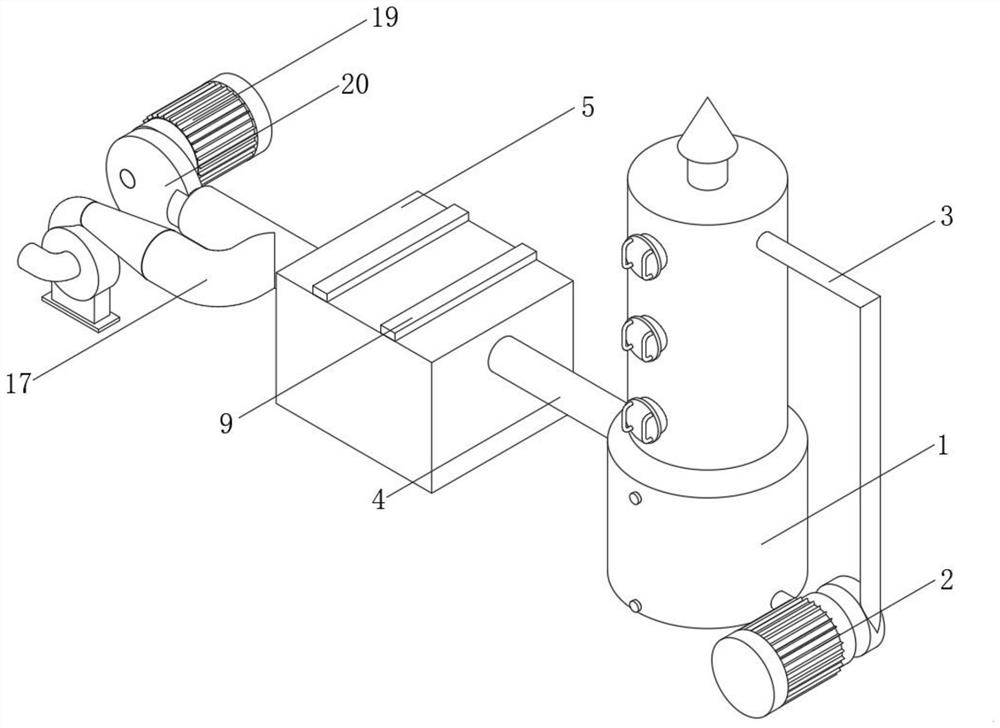

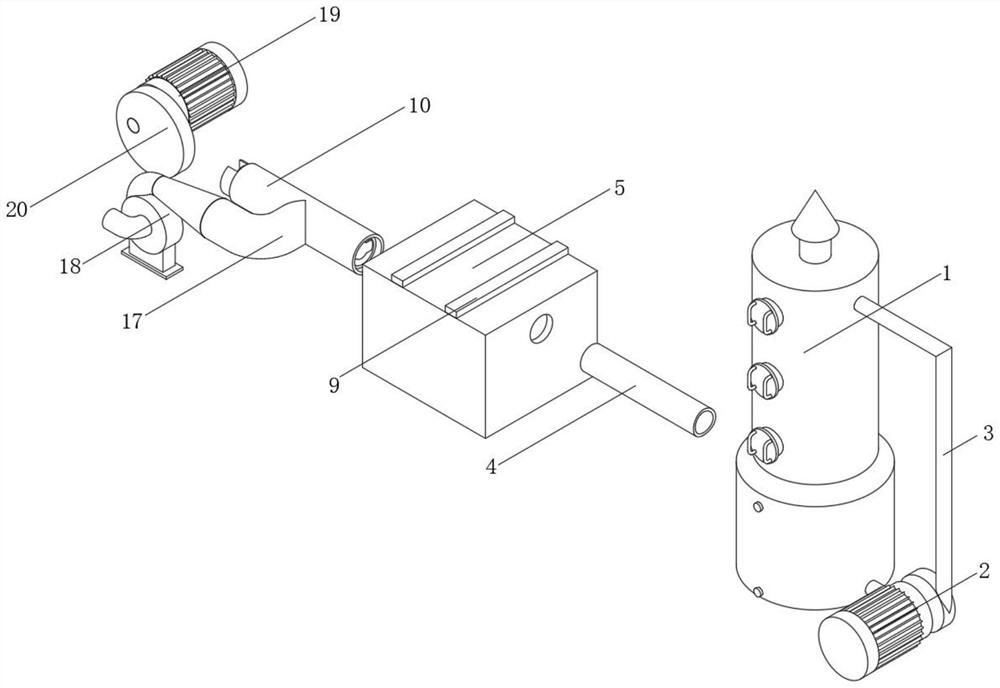

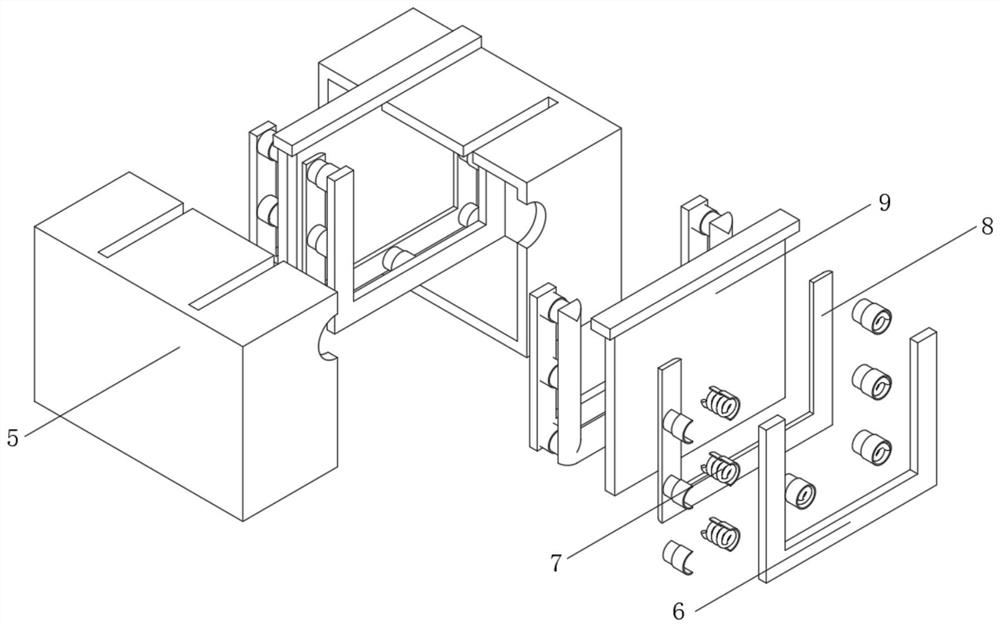

[0045] see Figure 1 to Figure 3 , the present invention provides a technical solution: the inner cavity of the deodorant box 5 is fixedly installed with a fixed frame 6, one side of the fixed frame 6 is fixedly connected with a support spring 7, and the side of the support spring 7 away from the fixed frame 6 is fixedly connected with a clip The holding sleeve 8 is provided with a bamboo charcoal plate 9 on one side of the holding sleeve 8 away from the fixing frame 6 . The fixed frame 6, the supporting spring 7 and the clamping sleeve 8 are all arranged into two groups, the bamboo charcoal plate 9 is located between the two clamping sleeves 8, and the edges and corners on the inner side of the clamping sleeve 8 are opened as arc surfaces, and the bamboo charcoal plate 9 is used for a period of time. , by pulling out the bamboo charcoal board 9, replace the new bamboo charcoal board 9 subsequently, make the bamboo charcoal board 9 insert from the upper direction of the deodor...

Embodiment 2

[0050] see Figure 5 to Figure 8 , On the basis of Embodiment 1, the spray tower 1 is provided with a flow regulating device 21 , and the flow regulating device 21 is fixed to the spray tower 1 .

[0051] The flow regulating device 21 includes:

[0052] Motor 2101, motor protective shell 2102, connecting shaft 2103, blocking plate 2104, communication pipe 2105, first gear 2106, second gear 2107, regulating plate 2108, first through hole 2109, second through hole 2110, third through hole 2111, the third gear 2112;

[0053] The motor 2101 is fixed on the inner upper surface of the spray tower 1 , the motor protection shell 2102 is provided outside the motor 2101 , and the motor protection shell 2102 is fixed to the inner upper surface of the spray tower 1 ;

[0054] The output end of the motor 2101 is fixed with one end of the connecting shaft 2103, and the other end of the connecting shaft 2103 is fixed with the first gear 2106;

[0055] The blocking plate 2104 is arranged b...

Embodiment 3

[0067] On the basis of Embodiment 1, a state parameter detection device of the blocking spring 14 is also included, and the state parameter detection device of the blocking spring 14 includes:

[0068] a displacement sensor, arranged on the restrictor plate 13, for detecting the displacement of the connection end between the restrictor plate 13 and the blocking spring 14;

[0069] a counter, which is set on the restrictor plate 13 and used to record the number of times the blocking spring 14 is compressed;

[0070] an alarm, the alarm is located on the deodorant box 5;

[0071] A controller, the controller is electrically connected with the displacement sensor, the counter and the alarm, respectively, the controller controls the operation of the alarm based on the displacement sensor and the counter, including:

[0072] Step 1: The controller obtains the state parameters of the blocking spring 14 based on the displacement sensor, the counter and the formula (1):

[0073] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com