Stirring device for chemical industry

A stirring device, chemical technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

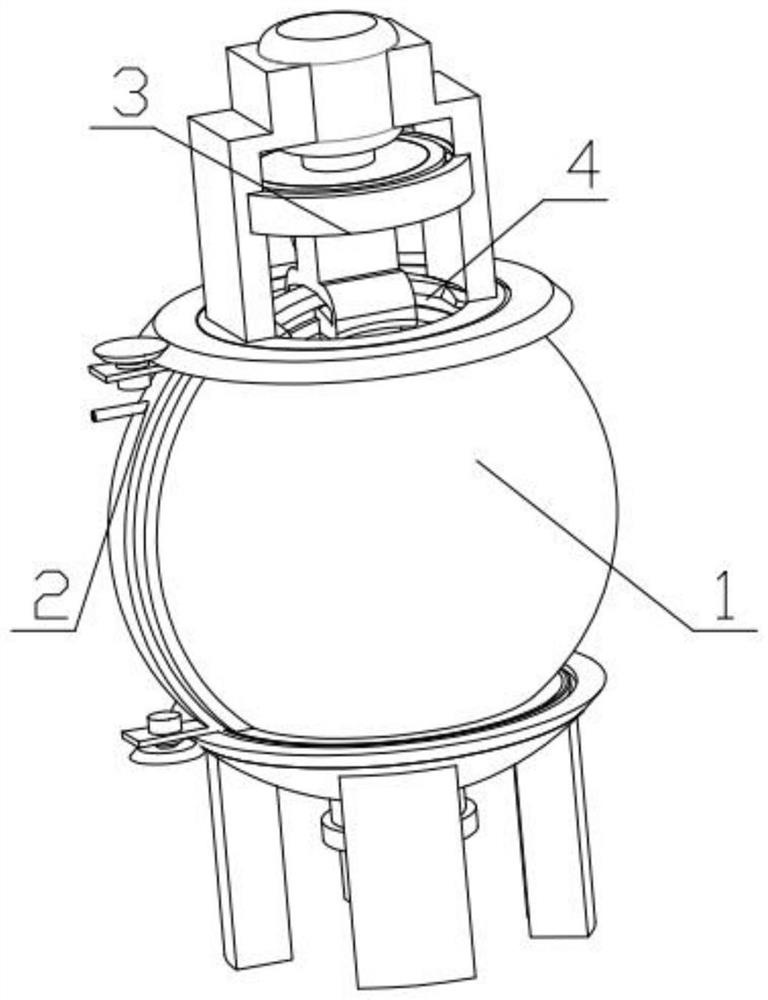

[0027] Combine below Figure 1-8 Illustrating this embodiment, a chemical stirring device includes a cylinder 1, a cooling mechanism 2, a power mechanism 3 and a stirring mechanism 4. The cooling mechanism 2 is slidably installed in a groove provided on the cylinder 1, and the cylinder 1 is screwed with the cooling mechanism 2, the power mechanism 3 is fixedly installed on the cylinder body 1, the stirring mechanism 4 is slidably installed in the groove set on the power mechanism 3, and the stirring mechanism 4 is engaged with the power mechanism 3.

specific Embodiment approach 2

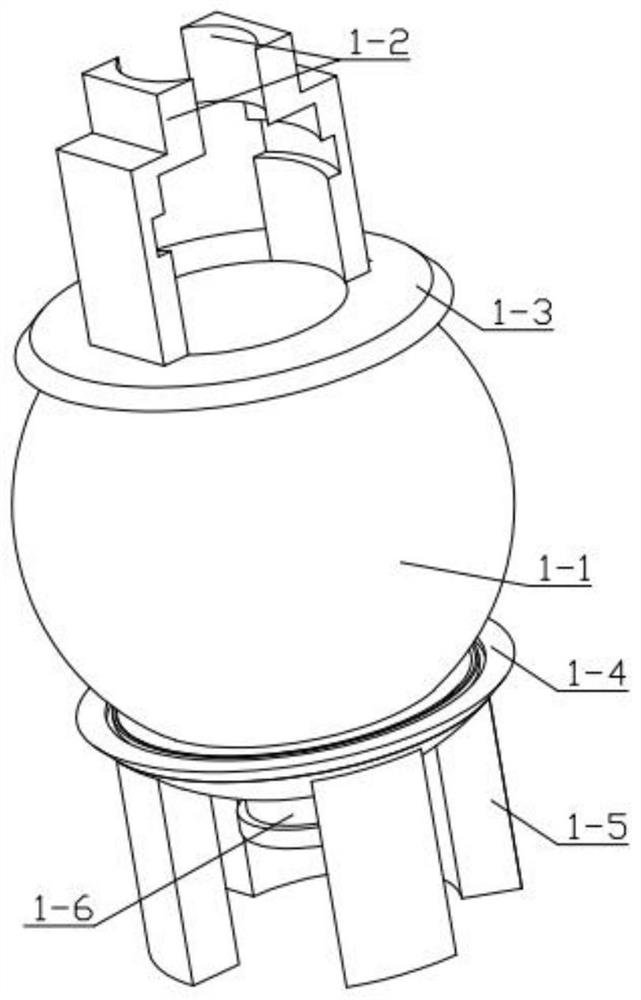

[0028] Combine below Figure 1-8 This embodiment will be described. This embodiment will further describe the first embodiment. The cylinder block 1 includes a circular cylinder block 1-1, a top mounting frame 1-2, an upper helical gear ring 1-3, and a lower helical gear ring 1. -4. Support legs 1-5, bottom discharge pipe 1-6, support legs 1-5 are fixedly installed on the circular cylinder body 1-1, and bottom discharge pipe 1 is fixedly installed on the circular cylinder body 1-1 -6, the upper helical gear ring 1-3 is fixed on the circular cylinder block 1-1, the lower helical gear ring 1-4 is fixed on the circular cylinder block 1-1, and the circular cylinder block 1-1 is fixed on the Top mount brackets 1-2 are installed.

specific Embodiment approach 3

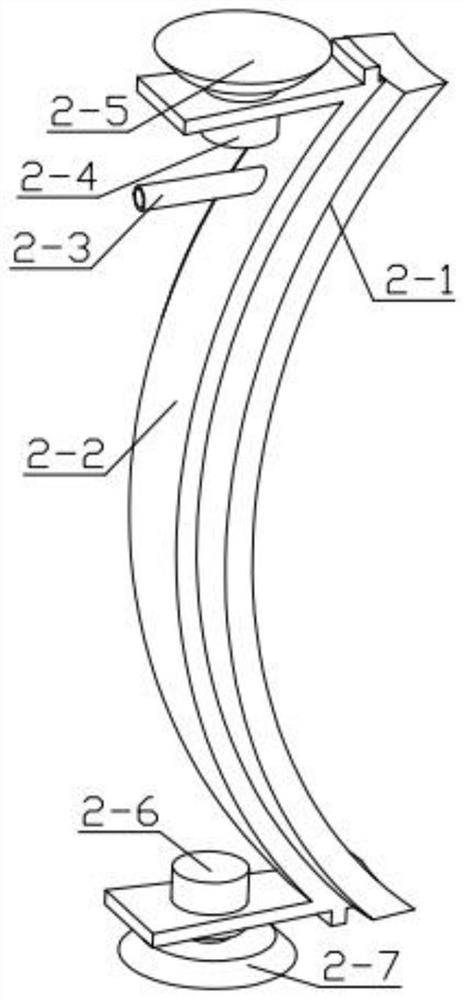

[0029] Combine below Figure 1-8 This embodiment will be described. This embodiment will further describe the second embodiment. The cooling mechanism 2 includes a wiping sea noodle strip 2-1, an arc top plate 2-2, a water inlet pipe 2-3, an upper motor 2-4, an upward slope Gear 2-5, lower motor 2-6, lower helical gear 2-7, a water inlet pipe 2-3 is fixedly installed in the groove set on the arc top plate 2-2, and the water outlet of the water inlet pipe 2-3 is used to wipe the sea noodles 2-1 contact, wipe the sea noodles 2-1 is fixedly installed on the arc top plate 2-2, the arc top plate 2-2 is slidably installed in the groove set on the upper helical gear ring 1-3, and the arc top plate 2-2 slides Installed in the groove set on the lower helical gear ring 1-4, the upper motor 2-4 is fixedly installed on the arc top plate 2-2, the output end of the upper motor 2-4 is fixedly installed with the upper helical gear 2-5, Gear 2-5 meshes with upper helical gear ring 1-3, lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com