Rotary electric vehicle hub cooling manipulator

An electric vehicle and rotary technology, applied in the direction of manipulators, electric vehicles, motors, etc., can solve the problems of high labor intensity, inability to transfer immediately, and easy burns, so as to avoid cumbersomeness and hidden dangers, reduce impact, and avoid The effect of manual picking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

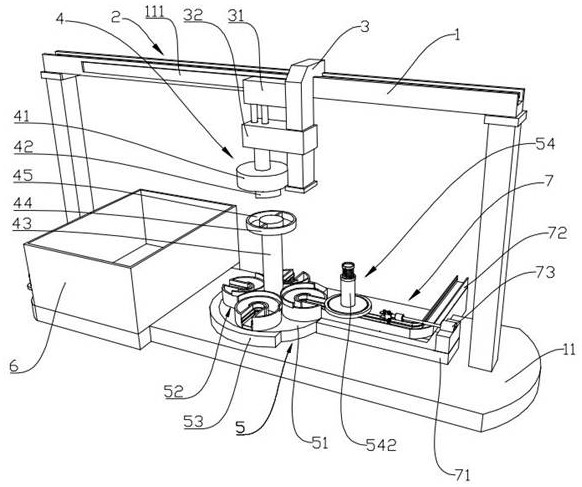

[0031] Example 1: as Figure 1 to Figure 11 As shown, the present invention provides a rotary electric wheel hub cooling manipulator, including a fixed frame 1, the top of the fixed frame 1 is connected with a walking frame 3 through a driving mechanism 2, and a lifting cylinder 31 is fixed on the walking frame 3. 3. The sliding sleeve at one end away from the fixed frame 1 is provided with a sliding seat 32. The sliding seat 32 is fixedly connected with the piston rod of the lifting cylinder 31. The sliding seat 32 is adsorbed by a lifting electromagnet 4 with a cooling placing frame 5. The cooling placing frame 5 includes The disc seat 51 is placed, and several hub placement bins 52 are evenly distributed along the circumferential direction on the disc seat 51. The bottom of the fixing frame 1 is provided with a bottom plate 11, and the bottom plate 11 is sequentially provided with a cooling water tank 6, an arc limit groove 53 and an upper and lower plate. The feeding devic...

Embodiment 2

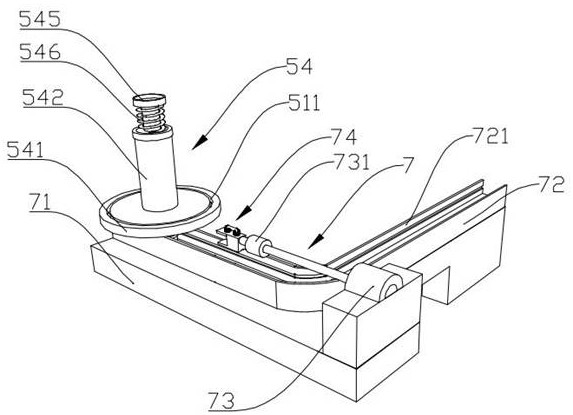

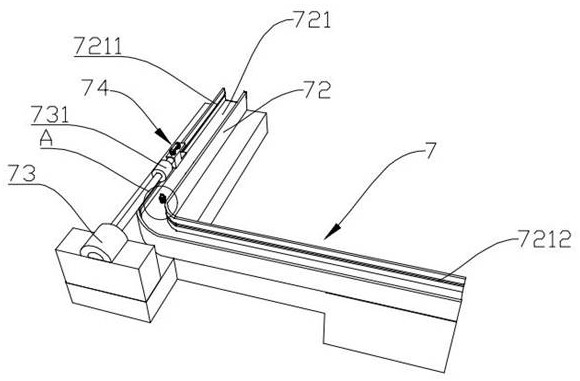

[0036] Embodiment 2: On the basis of Embodiment 1, as Figure 1 to Figure 4 and Figures 6 to 8 As shown, the wheel hub placement rack 54 includes a support plate 541, an L-shaped chute 721 is provided on the L-shaped conveying track 72, the top surface of the L-shaped chute 721 is flush with the top surface of the silo body 521, and the support plate 541 is slidably arranged on the On the top surface of the L-shaped chute 721, the width of the L-shaped chute 721 is the same as the distance between the first support plate 5231 and the second support plate 5232. The support plate 541 is fixedly provided with a support column 542. The support column 542 One end of the support column 542 is located in the L-shaped chute 721, one end of the support column 542 is rotatably sleeved with a positioning ring 543, the other end of the support column 542 is movably provided with a buffer rod 544, and the end of the buffer rod 544 away from the support column 542 is provided with a buffer...

Embodiment 3

[0040] Embodiment 3: On the basis of Embodiment 1, as Figure 1 to Figure 3 As shown, the opposite inner walls of the L-shaped chute 721 are also provided with a first chute 7211 and a second chute 7212 that communicate with the first guide slot 5233 and the second guide slot 5234 respectively, and the positioning ring 543 is slidably clamped. Between the first chute 7211 and the second chute 7212, when the hub placement frame 54 moves in the L-shaped chute 721, the support plate 541 can be guided by the first guide groove 5233 and the second guide groove 5234. Moving (ie, moving from the L-shaped chute 721 to the wheel hub placement bin 52 ) is beneficial to keep the wheel hub placement frame 54 stable when moving in the L-shaped chute 721 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com